Composite buffer sheet

A composite buffer and sheet technology, applied in the field of packaging, can solve the problems of buffer performance, creep performance bearing capacity, weak puncture resistance, cost, storage and transportation costs increase packaging waste, and the volume of packaging parts increases. Achieve overall cost reduction, lower storage and transportation costs, and reduced packaging size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

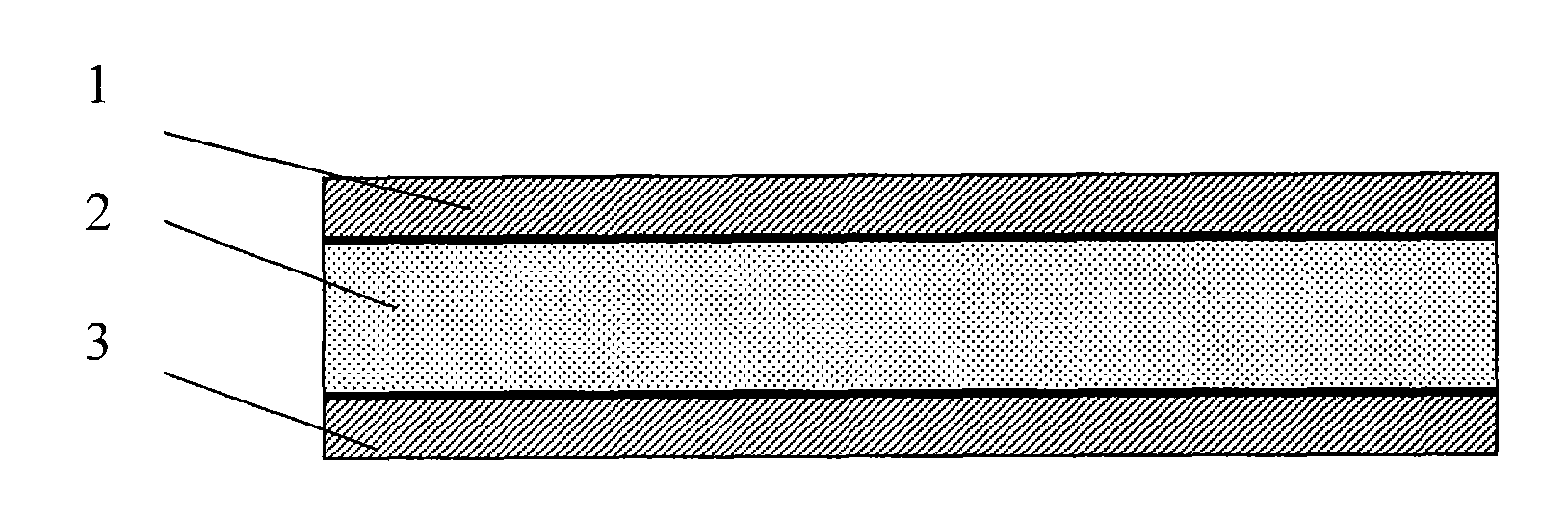

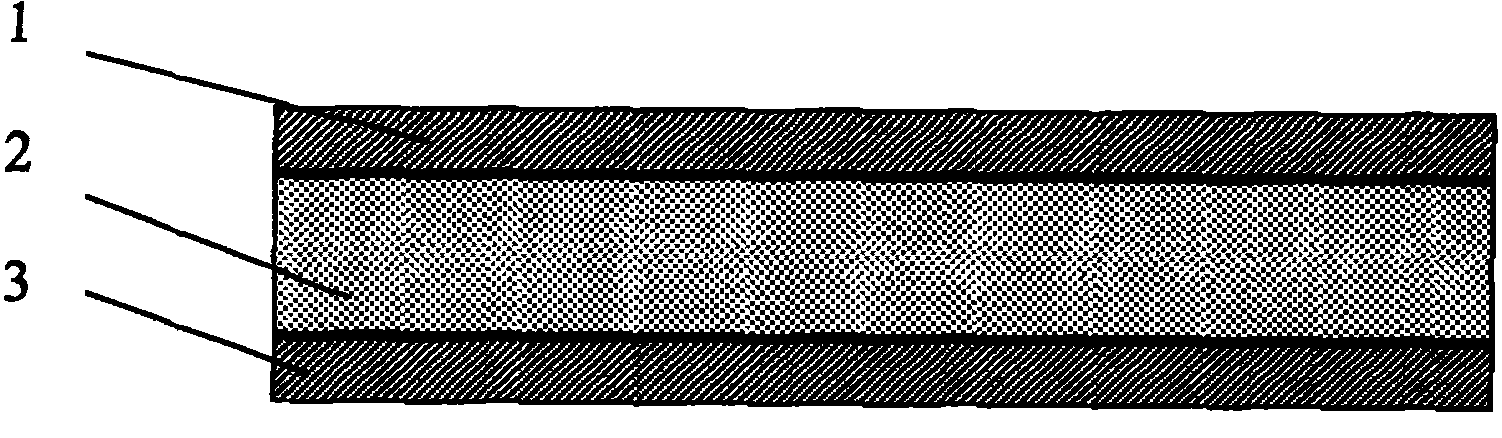

[0013] Such as figure 1 As shown, the composite cushioning sheet of the present invention consists of three elastic cushioning layers, and the middle elastic cushioning layer 2 in the middle is made of a low-density polyethylene foam board, wherein the rest of the elastic cushioning layer 1 and the elastic cushioning layer 3 are respectively made of high-density polyethylene foam boards, and are bonded to the upper side and the lower side of the middle elastic buffer layer 2 respectively.

[0014] Further, the thickness of the elastic buffer layer 2 is greater than the thickness of the elastic buffer layer 1 and the elastic buffer layer 3 .

[0015] Further, the elastic buffer layer 1 and the elastic buffer layer 3 have the same thickness.

[0016] Further, the density of the middle elastic buffer layer 2 is smaller than that of the elastic buffer layer 1 and the elastic buffer layer 3 .

[0017] Further, the elastic coefficient of the middle elastic buffer layer 2 is smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com