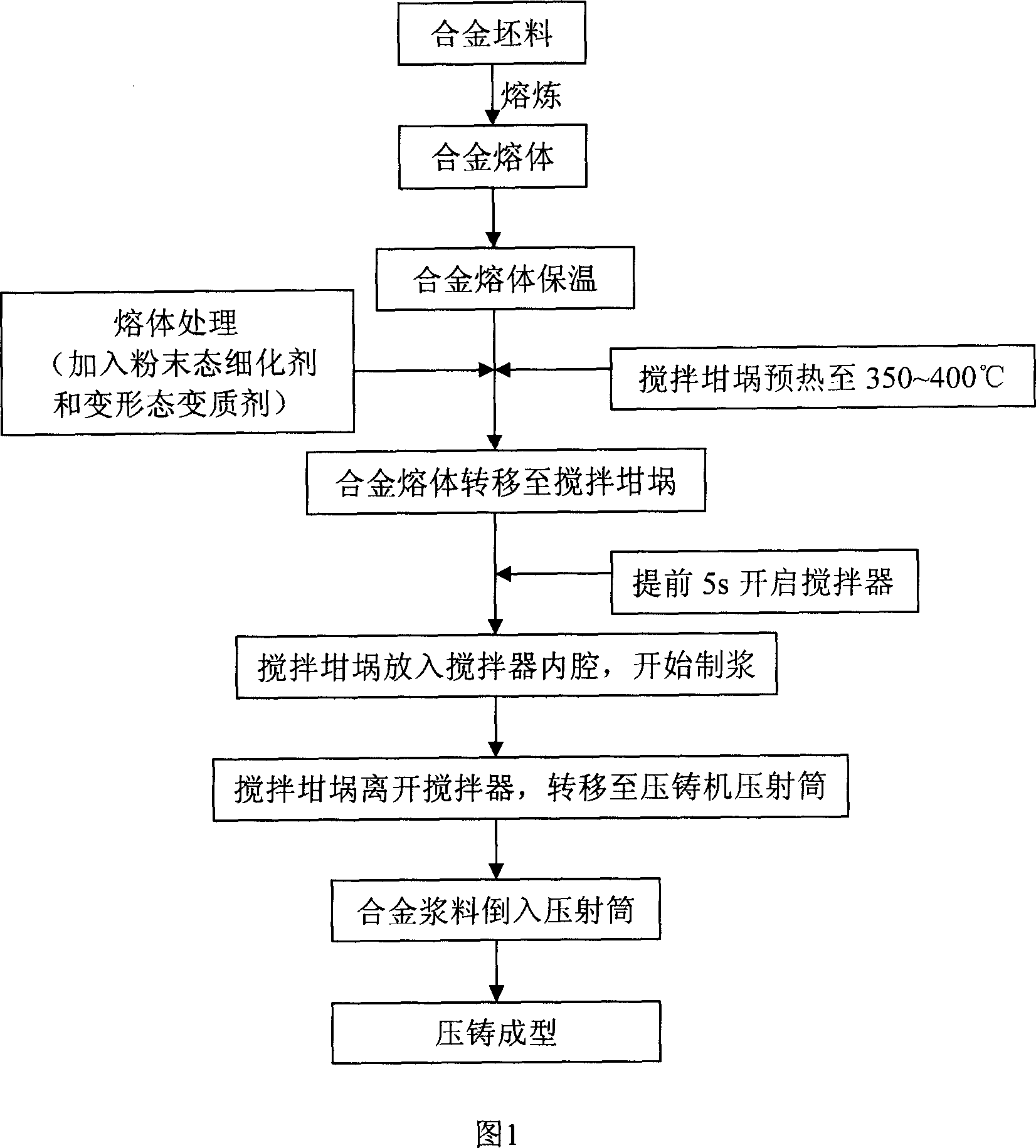

Slurrying-forming separated aluminium alloy rheological forming method

A rheological forming and aluminum alloy technology, which is applied in the field of pulping-forming separate aluminum alloy rheological forming, can solve the problems of undisclosed technical details, and achieve the effects of improved production efficiency and strong process applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] 1. Preparation of superheated liquid alloy

[0042] (1.1) Preparation of superheated melt. There are no special requirements on the equipment, and various heating methods in the prior art can be used, but it is necessary to ensure that the temperature of the melt is uniform, and the melt is pure and free from contamination.

[0043] (1.2) Melt treatment process. Carried out in a traditional air resistance holding furnace. First, it is required to select a suitable master alloy. Taking A356 alloy as an example, micron-sized Al-5Ti-B alloy powder should be used as the refiner, and extruded Al-10Sr binary alloy with a deformation of about 50% should be used as the modifier. Second, compared with the traditional bulk master alloy, the addition of master alloy powder is slightly more and the standing time is shorter. Thirdly, if the particle size of the master alloy powder is different, the adding temperature will be different, the finer the powder particles, the lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com