Device and method for preparing pure titanium with liquid alloys as electrodes

A liquid alloy and pure titanium technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high environmental pollution, high production cost of metal titanium, and restrictions on the application of metal titanium, and achieve the goal of shortening the process flow and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

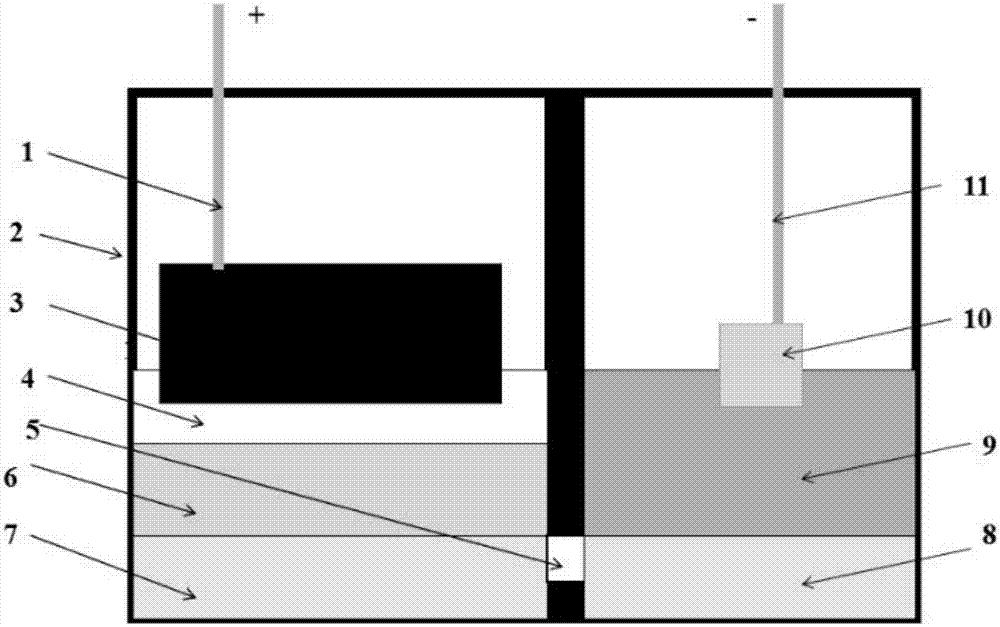

[0033] (1) First, in the first electrolyzer, select Na 2 O-SiO 2 -TiO 2 Melt as electrolyte, TiO added in molten salt 2 As raw material, choose CaCl 2 As a transition anode, graphite is used as an inert anode, and Ti-Cu alloy is used as the cathode of the first electrolytic cell;

[0034] (2) After the start of electrolysis, Na 2 O-SiO 2 -TiO 2 The Ti element in the melt will continuously discharge at the cathode and enter the Ti-Cu liquid cathode;

[0035] (3) Na 2 O-SiO 2 -TiO 2 Oxygen in the element will pass through the CaCl 2 The transition cathode reaches the surface of the graphite anode, loses electrons, and is oxidized to O 2 , while further reacting to produce CO x ;

[0036] (4) As the electrolysis continues, the titanium element entering the Ti-Cu liquid cathode continues to increase, and the liquid Ti-Cu alloy flows into the second electrolytic cell and is used as the anode of the second electrolytic cell;

[0037] (5) In the second electrolytic cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com