Liquid alloy, preparing method of liquid alloy and application of liquid alloy

A technology of liquid alloys and mixtures, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, and usage of superconductor elements, etc., can solve problems such as incompetence, high requirements for connecting materials, and complicated preparation process of superconducting joints, etc., to achieve Avoiding accidental loss and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

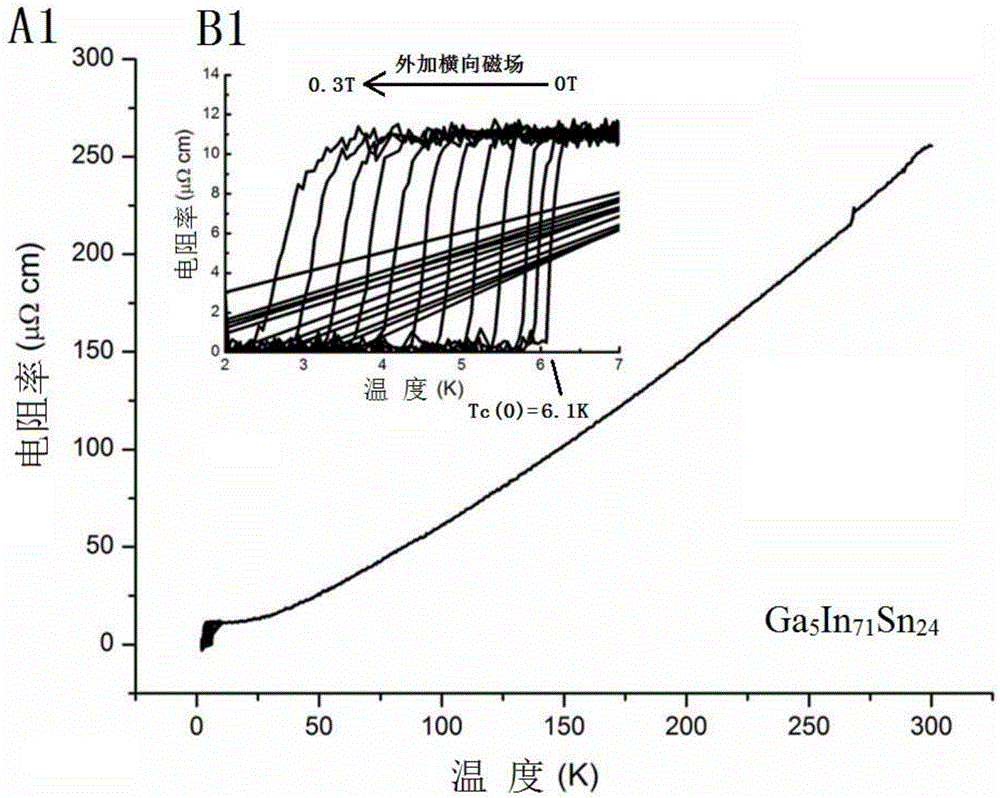

[0057] Gallium, indium and tin were weighed at a weight ratio of gallium:indium:tin=5:71:24. Then, under the condition of isolating the air, first heat the gallium until it is completely melted, continue to keep the state of isolating the air, add tin and heat it to above 235°C, and stir at the same time, after the tin is completely melted, add indium and keep the temperature above 120°C , stirring at the same time, after the indium is completely melted, it is naturally cooled to room temperature, so as to obtain a weight ratio of Ga 5 In 71 sn 24 liquid alloy.

Embodiment 2

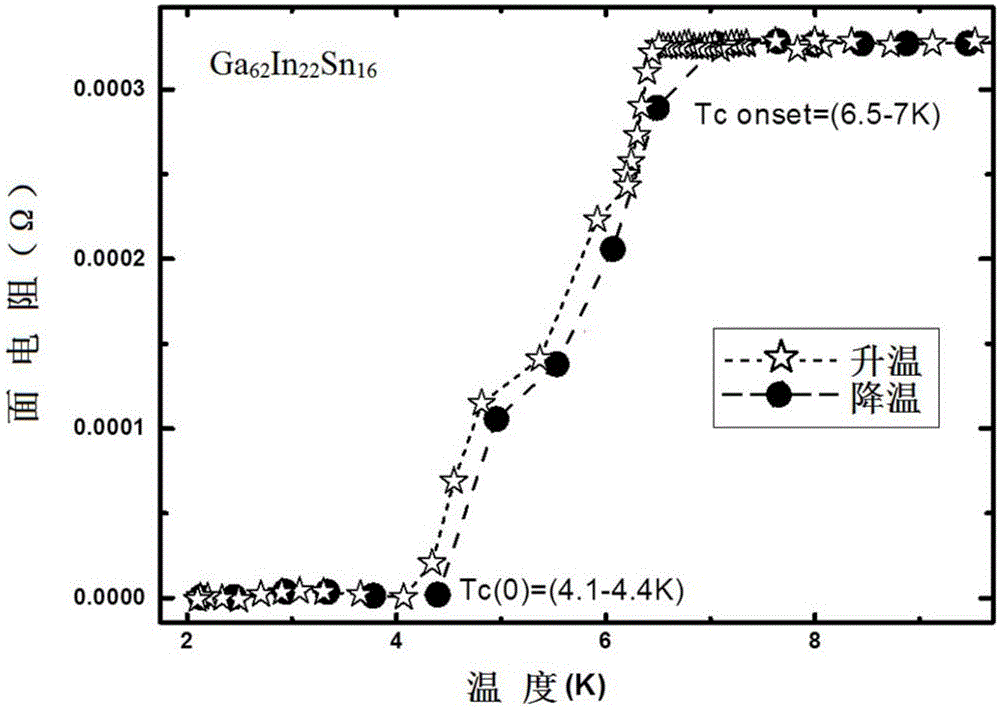

[0059] In addition to weighing gallium, indium and tin respectively at a weight ratio of gallium:indium:tin=62:22:16. Obtained weight ratio is Ga with the same method as embodiment 1 62 In 22 sn 16 liquid alloy.

Embodiment 3

[0061] In addition to weighing gallium, indium and tin respectively at a weight ratio of gallium:indium:tin=40:40:20. Obtained weight ratio is Ga with the same method as embodiment 1 40 In 40 sn 20 liquid alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com