Pressure difference injection moulding method and equipment for amorphous magnesium alloy

A molding method and molding equipment technology, which are applied in the field of amorphous magnesium alloy preparation engineering and equipment, can solve problems such as being limited to the experimental research stage and have not been reported, and achieve the effects of good adaptability, simple operation, and stable and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

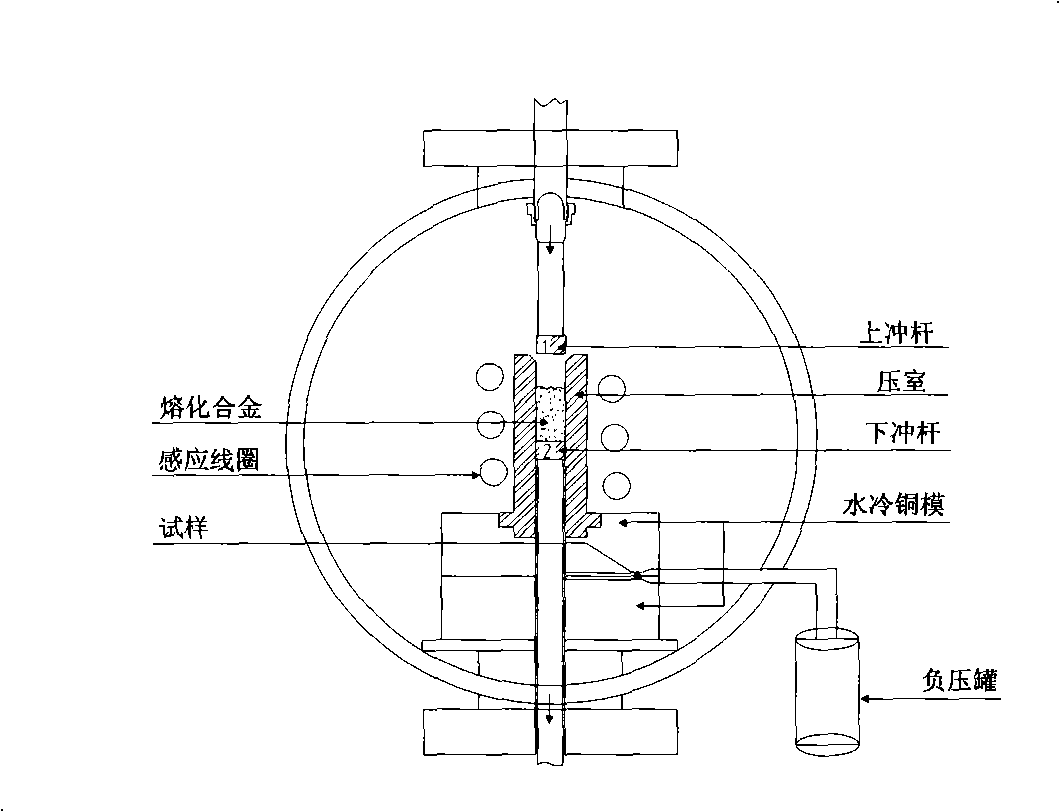

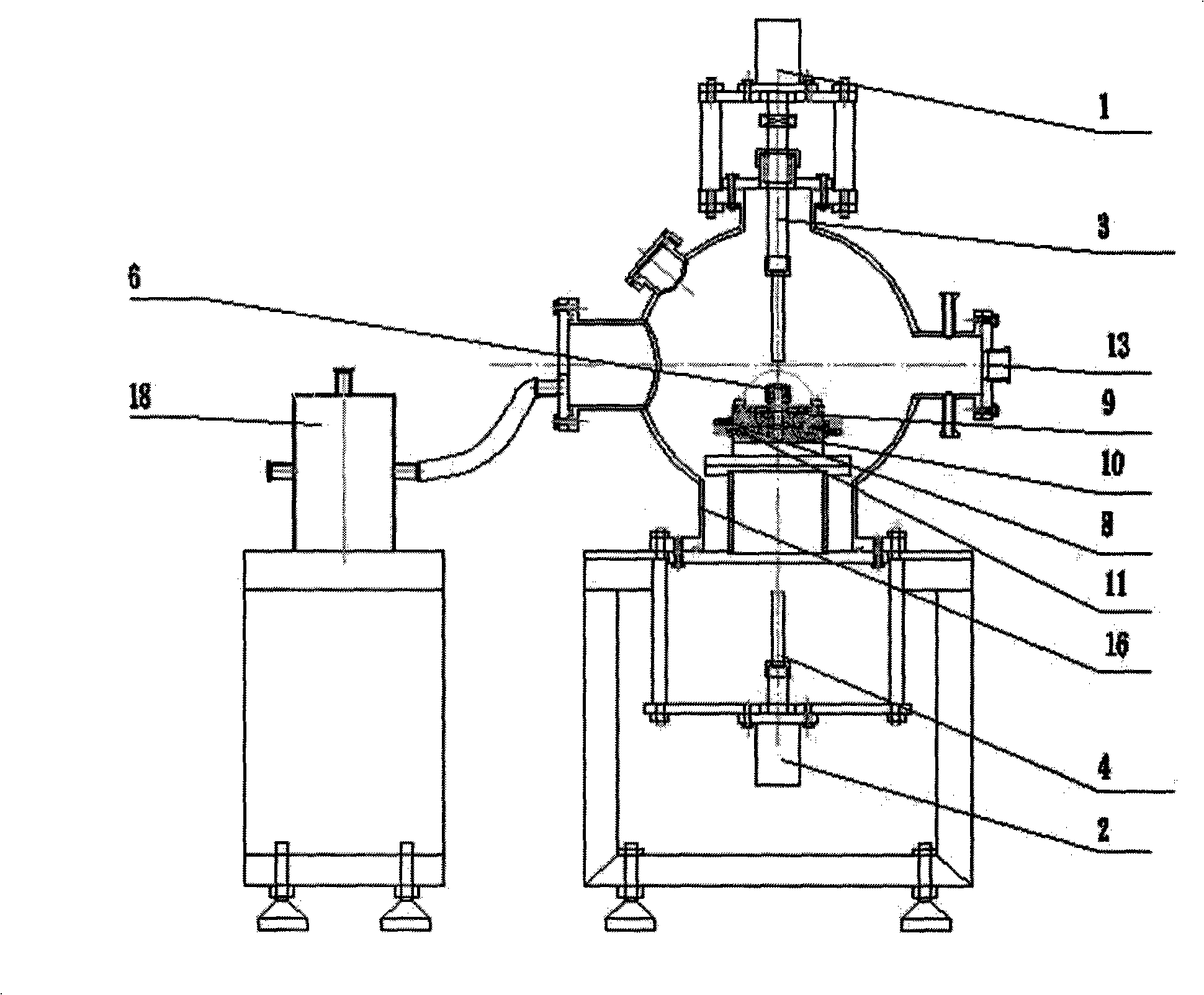

[0019] figure 1 It is a schematic diagram of the device structure of the present invention. like figure 1 As shown, an amorphous magnesium alloy differential pressure injection molding equipment, the equipment includes an upper hydraulic cylinder (1), a lower hydraulic cylinder (2), an upper pressure rod (3), a lower pressure rod (4), an induction power supply ( 5), heating coil (6), pressure chamber (7), pressure chamber feed port (8), mold inlet (9), cooling device (11), mold (10), working cavity (12), vacuum Port (13), protective gas inlet (14), furnace door (15), vacuum pump (16), protective gas cylinder (17), negative pressure tank (18), quick opening valve (19), negative pressure valve (20) ; The upper hydraulic cylinder (1) and the lower hydraulic cylinder (2) are respectively connected to the upper pressure rod (3) and the lower pressure rod (4) to provide i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com