Thermal interface material for packaging and radiating chip and preparation method thereof

A thermal interface material and chip packaging technology, applied in heat exchange materials, chemical instruments and methods, electrical components, etc., can solve the problems of poor contact and high thermal resistance, reduce thermal resistance of packaging, improve heat dissipation capacity and stability , Superior thermal contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

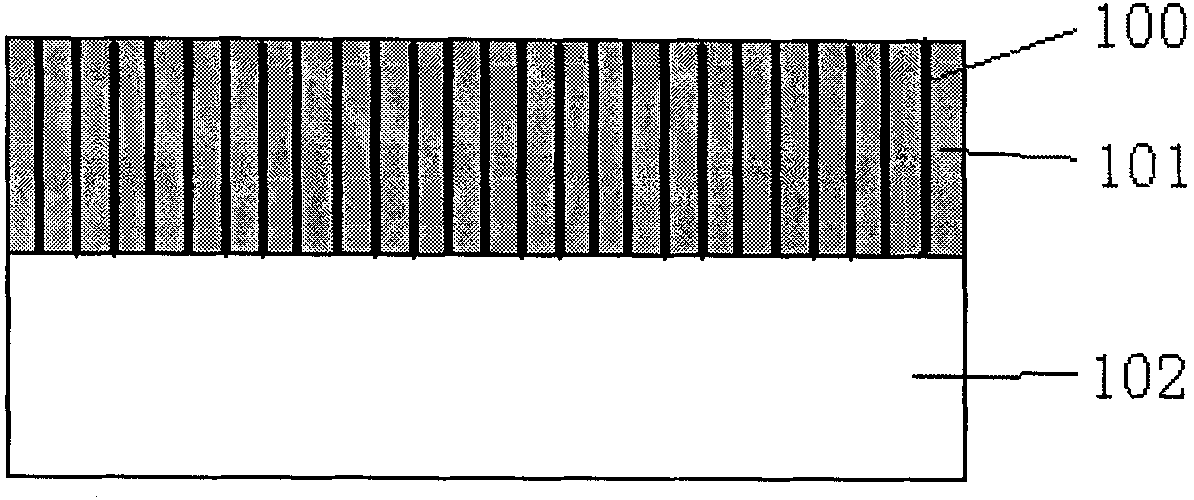

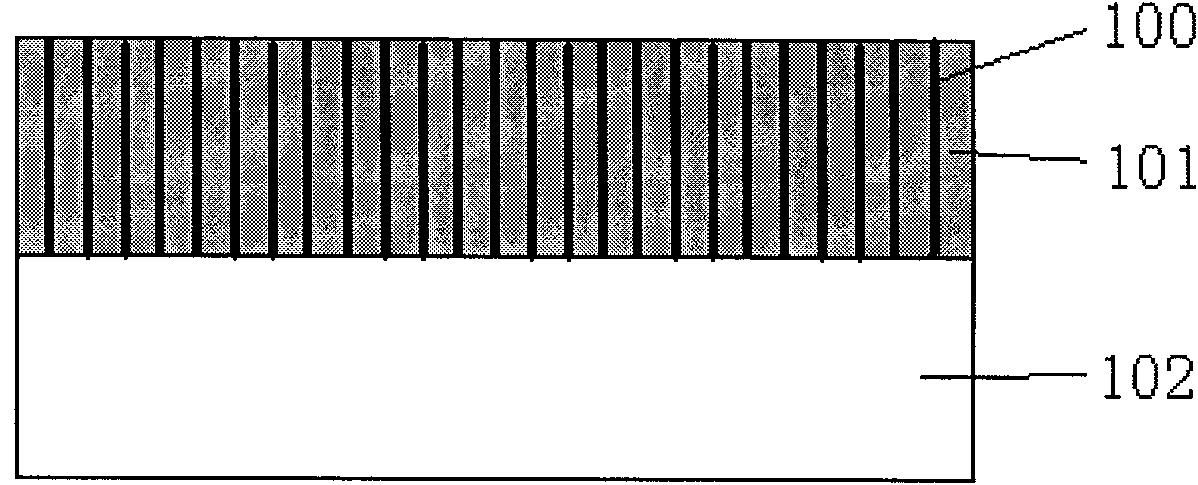

[0019] In order to meet the requirements of high-performance chip cooling technology and overcome the shortcomings of high thermal resistance and poor contact of existing thermal interface materials, the invention provides a thermal interface material used for chip packaging and having excellent heat dissipation. Such as figure 1 Shown is a schematic cross-sectional view of the thermal interface material, and it can be seen that the thermal interface material includes a carbon nanotube array formed by carbon nanotubes 100 on a substrate 102 and liquid metal 101 . in,

[0020] These carbon nanotubes 100 are all formed in a state perpendicular to the substrate 102 during preparation, and the diameter of the carbon nanotubes is about 2nm-100nm. The carbon nanotube array may be a single-wall carbon nanotube array, may be a double-wall carbon nanotube array, may also be a multi-wall carbon nanotube array or a single-wall, double-wall carbon nanotube array. The substrate 102 is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com