Gallium liquid metal material and application of gallium liquid metal material to teletransmission pressure and different pressure transmitter

A differential pressure transmitter, liquid metal technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of measuring diaphragm bulging, affecting pressure conduction, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

[0015] An application of a gallium liquid metal material in a remote pressure and differential pressure transmitter. The pressure and differential pressure transmitter has a capillary 1, and all or part of the capillary 1 is filled with a gallium liquid metal material. The gallium liquid The parameter requirements of metal materials are: thermal conductivity > 10W / m·k; kinematic viscosity is 5×10 -8 -9×10 -8 m 2 / s; melting point 1000°C. In this embodiment, the thermal conductivity is 15W / m·k; the kinematic viscosity is 7.11×10 -8 m 2 / s; melting point 8°C; boiling point > 1000°C.

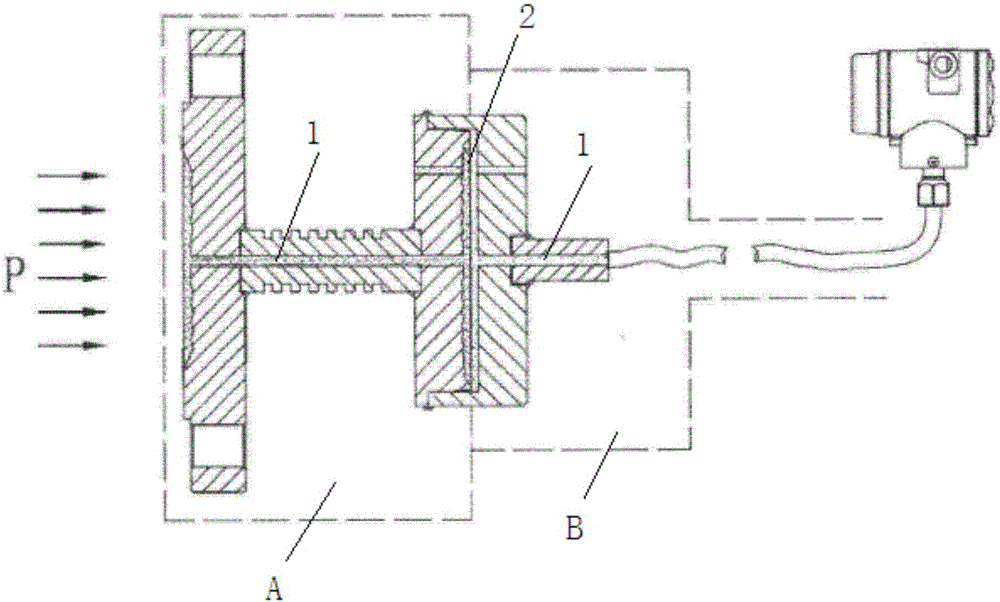

[0016] combine figure 1 As shown, it is embodiment 1 of the present invention, part of the capillary is filled with the gallium liquid metal material, as shown in Figure A area; the other part of the filling hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com