Preparation method of low pressure guide connected hollow blade

A low-pressure guide and blade technology, applied in the field of precision casting, can solve the problems of low qualified rate of finished products and high brazing cost, and achieve the effect of refining grain structure, improving manufacturing qualification rate and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

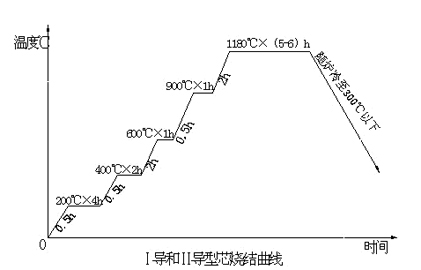

[0021] Embodiment 1: The preparation of the first-stage guide conjoined hollow blade is carried out according to the following process steps:

[0022] (1) Preparation of the hollow conjoined blade core: First, the ingredients are formulated according to the following weight percentages, 65% of quartz glass powder, 15% of mullite powder, 20% of additives, and 18% of plasticizer; then The well-stirred core powder is injected into the core pressing equipment, the pressing temperature is 96°C, the injection pressure is 4.0MPa, after holding the pressure for 22s, it is taken out and put into the calibration mold to make the mother core; finally put it in the material tank Insert the quartz glass powder with a height of 180mm, insert the mother core into the powder vertically, the distance between the lower end of the mother core and the bottom of the material tank is controlled at more than 30mm, and the distance between the mother core is 30mm, use quartz glass powder To fill the ...

Embodiment 2

[0026] Embodiment 2: The preparation of the two-stage guide hollow conjoined blade is carried out according to the following process steps:

[0027] (1) Preparation of the hollow conjoined blade core: First, the ingredients are formulated according to the following weight percentages, 65% of quartz glass powder, 15% of mullite powder, 20% of additives, and 20% of plasticizer; then The well-stirred core powder is injected into the core pressing equipment, the pressing temperature is 105°C, the injection pressure is 4.8MPa, after holding the pressure for 20s, it is taken out and put into the calibration mold to make the mother core; finally, put it in the material tank Insert the quartz glass powder with a height of 200mm, insert the mother core into the powder vertically, control the distance between the lower end of the mother core and the bottom of the tank at more than 30mm, and the distance between the mother core is 30mm, use quartz glass powder To fill the entire tank, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com