Quick determination device for surface tension of liquid metal and liquid alloy

A liquid alloy and surface tension technology, applied in the field of metallurgy and casting, can solve the problems of affecting the measurement accuracy, blowing out the bubble pressure difference curve, and hindering the promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

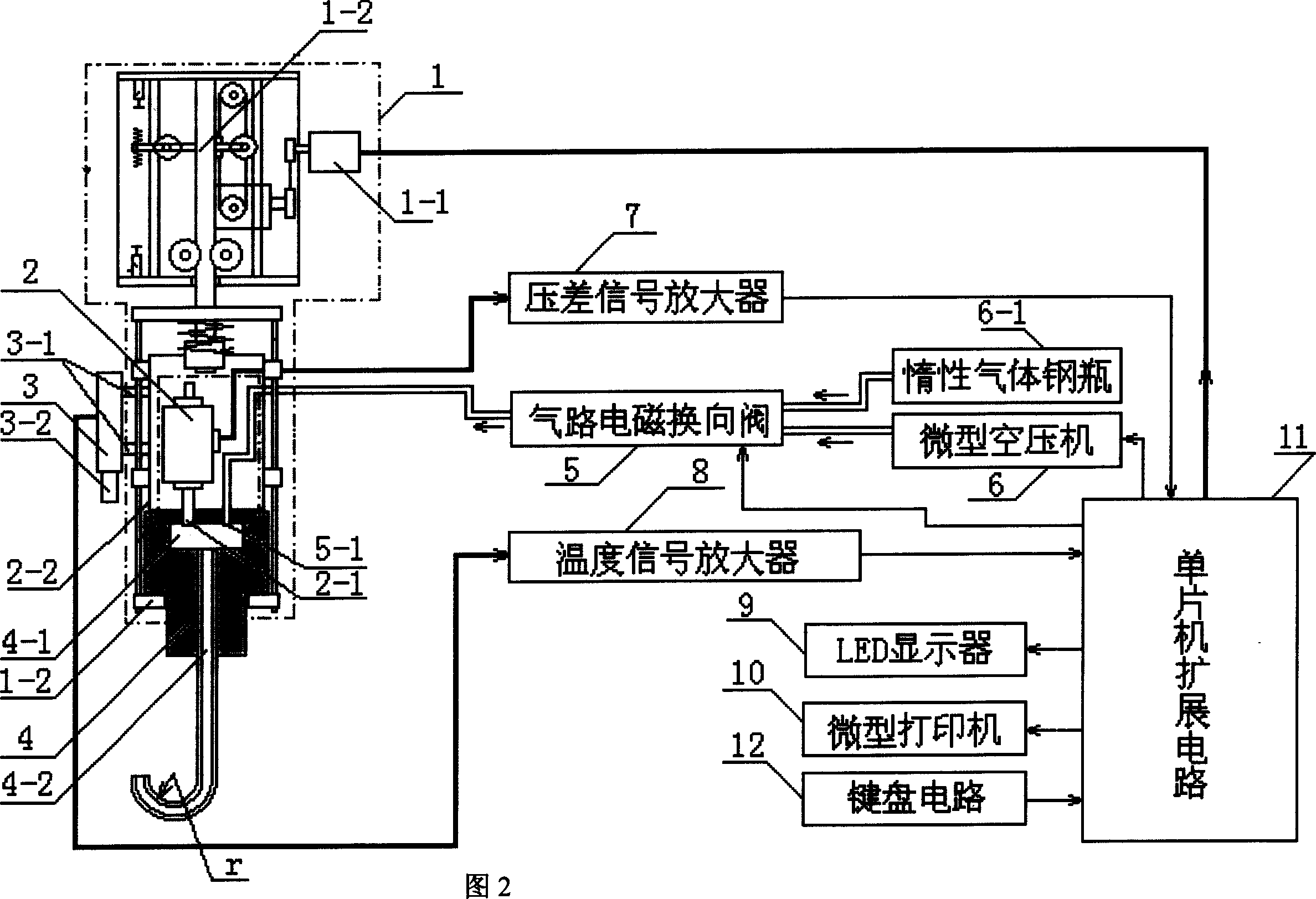

[0005] This embodiment is described in conjunction with Fig. 2. This embodiment consists of a probe up and down drive mechanism 1, a micro pressure difference sensor 2, an infrared temperature sensor 3, a heat-resistant probe 4, an air path electromagnetic reversing valve 5, a miniature air compressor 6, an inert gas Steel cylinder 6-1, differential pressure signal amplifier 7, temperature signal amplifier 8, LED display 9, micro-printer 10, single-chip microcomputer expansion circuit 11, keyboard circuit 12; the power supply control signal input of the motor 1-1 in the probe up and down drive mechanism 1 connected to the power supply control signal output end of the single-chip microcomputer expansion circuit 11, the lower end hoof-shaped manipulator of the traction frame 1-2 in the probe up and down drive mechanism 1 is connected with the outer surface of the heat-resistant probe 4, and the high-temperature-resistant quartz tube in the heat-resistant probe 4 The upper port of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com