Rail vehicle vehicle terminal relation integration testing stand

A technology of comprehensive test bench and vehicle-end relationship, applied in the field of comprehensive test bench for vehicle-end relationship, can solve problems such as lack of vehicle-end detection equipment, and achieve the effect of ensuring the accuracy and reliability of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

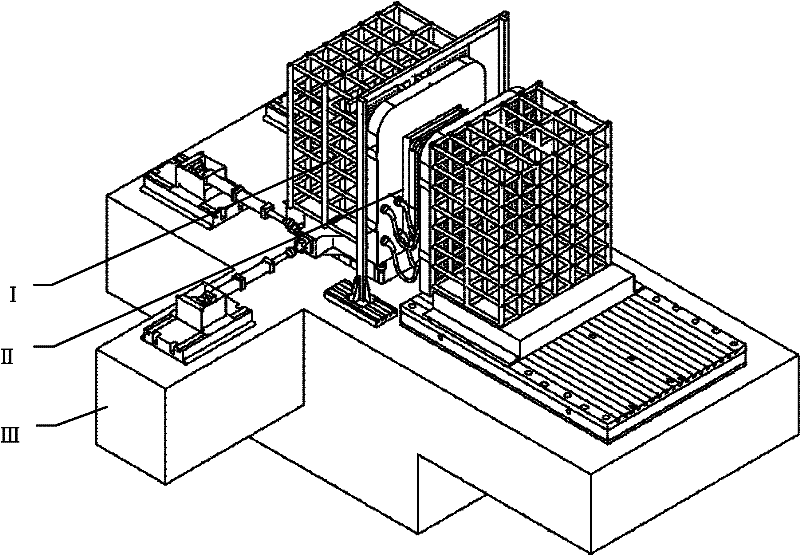

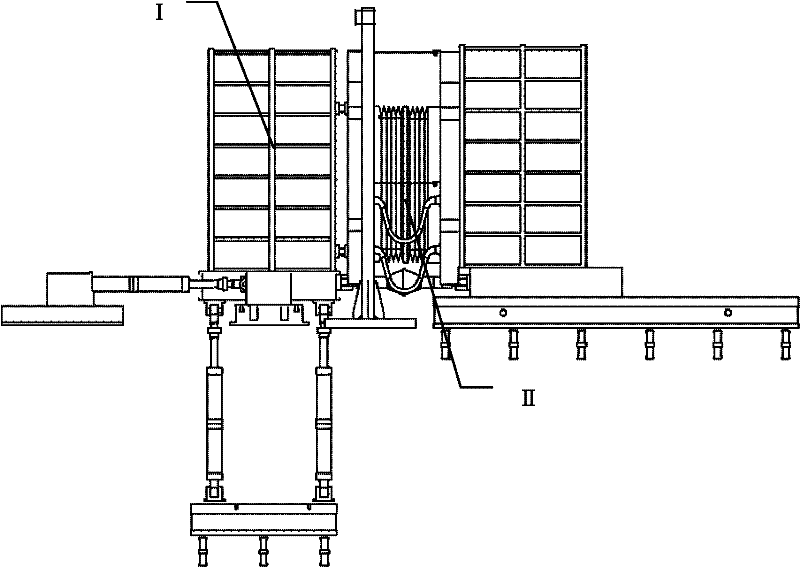

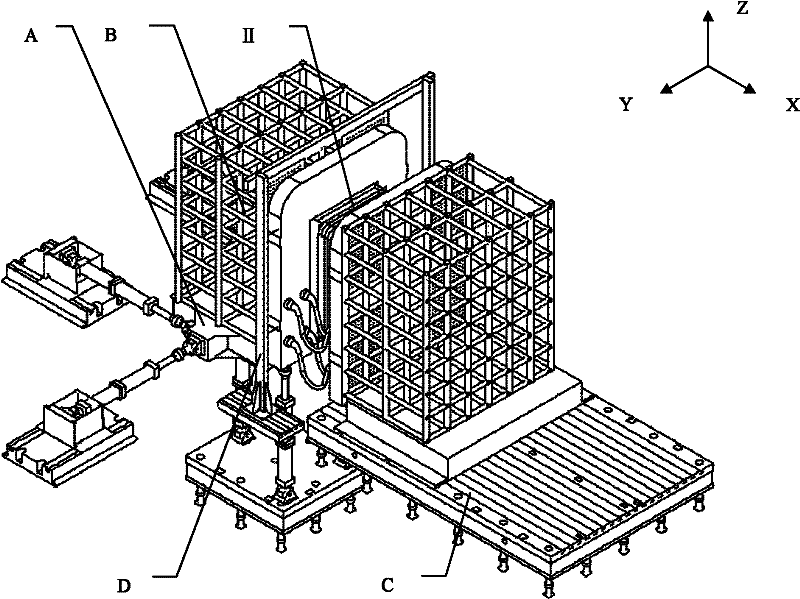

[0041] refer to figure 1 , 2 , 3, 4, the rail vehicle vehicle end relation comprehensive test bench of the present invention is composed of six degrees of freedom motion platform assembly A, truss vehicle end wall assembly B, simulated vehicle frame and fixed platform assembly C, test assembly D. Composed of electronic control part and hydraulic pump station.

[0042] The six-degree-of-freedom motion platform assembly A is installed on the left end of the concrete foundation III, the simulated vehicle frame and fixed platform assembly C are installed on the right end of the concrete foundation III, and the horizontal direction of the motion platform f in the six-degree-of-freedom motion platform assembly A (along axis direction) symmetry plane is coplanar with the longitudinal (along the X-axis direction) symmetry plane of the fixed platform l in the simulated vehicle frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com