Method for smelting return scrap of martensitic stainless steel used for impeller

A technology of martensitic stainless steel and return materials, applied in the field of metallurgy, can solve the problems of return materials or waste forgings that cannot be used, and achieve the effects of improving various mechanical performance indicators, reducing defects, and improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

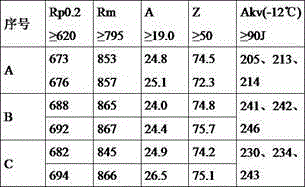

Examples

Embodiment 1

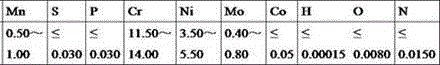

[0024] Carry out baking and shot blasting treatment on the return materials and waste forgings produced during the preparation of the impeller, clean the surface of the return materials and waste forgings, and then place them in a vacuum induction furnace at the same time to start vacuuming the vacuum equipment, when the vacuum degree is ≤ 3.2Pa , heat up to 1030°C by power transmission, refining for 15 minutes, and then heat the alloy melt to 1610°C for refining, the refining time is 30 minutes, in which the vacuum degree is controlled to be ≤12.1Pa during the melting process of the alloy melt, and the vacuum degree is ≤3.2 during the refining process Pa; After refining, cool down to the conjunctiva on the surface of the alloy melt. Heat the alloy melt of the conjunctiva to 1550°C and cast it into a primary ingot.

[0025] The chemical composition of the primary ingot was analyzed by weight percentage as Ni 4.18%, Cr 12.85%, Mo 0.61%, Mn 0.87%, Si 0.24%, C 0.039%, and the bal...

Embodiment 2

[0032] Carry out baking and shot blasting treatment on the return materials and waste forgings produced during the preparation of the impeller, clean the surface of the return materials and waste forgings, and then place them in a vacuum induction furnace at the same time to start vacuuming the vacuum equipment, when the vacuum degree is ≤ 3.2Pa At this time, the temperature is raised to 1032°C by power transmission, refining for 16 minutes, and the temperature of the alloy melt is raised to 1620°C for refining. The refining time is 28 minutes. During the melting process of the alloy melt, the vacuum degree is controlled to be ≤12.1Pa, and the vacuum degree is controlled to be ≤3.2 during the refining process. Pa; After refining, cool down to the conjunctiva on the surface of the alloy melt. Heat the alloy melt of the conjunctiva to 1550°C and cast it into a primary ingot.

[0033]The chemical composition of the primary ingot was analyzed by weight percentage as Ni 4.25%, Cr 1...

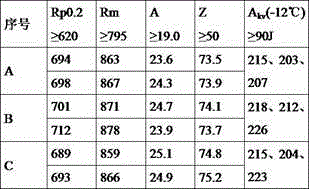

Embodiment 3

[0040] The production process routes in Examples 1 and 2 are adopted, and the produced impeller forgings are treated in a fixed heat treatment process system, and the obtained mechanical properties are shown in Table 4.

[0041] Table 4 Mechanical properties of impeller products

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com