Low-carbon steel wire rod and manufacturing method thereof

A manufacturing method and technology of low-carbon steel, applied in the field of steel rolling, can solve the problems of customer variability, shrinkage cavity and surface defects, high scrap return, etc., and achieve the effect of improving the pass rate, reducing surface defects, and reducing scrap return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

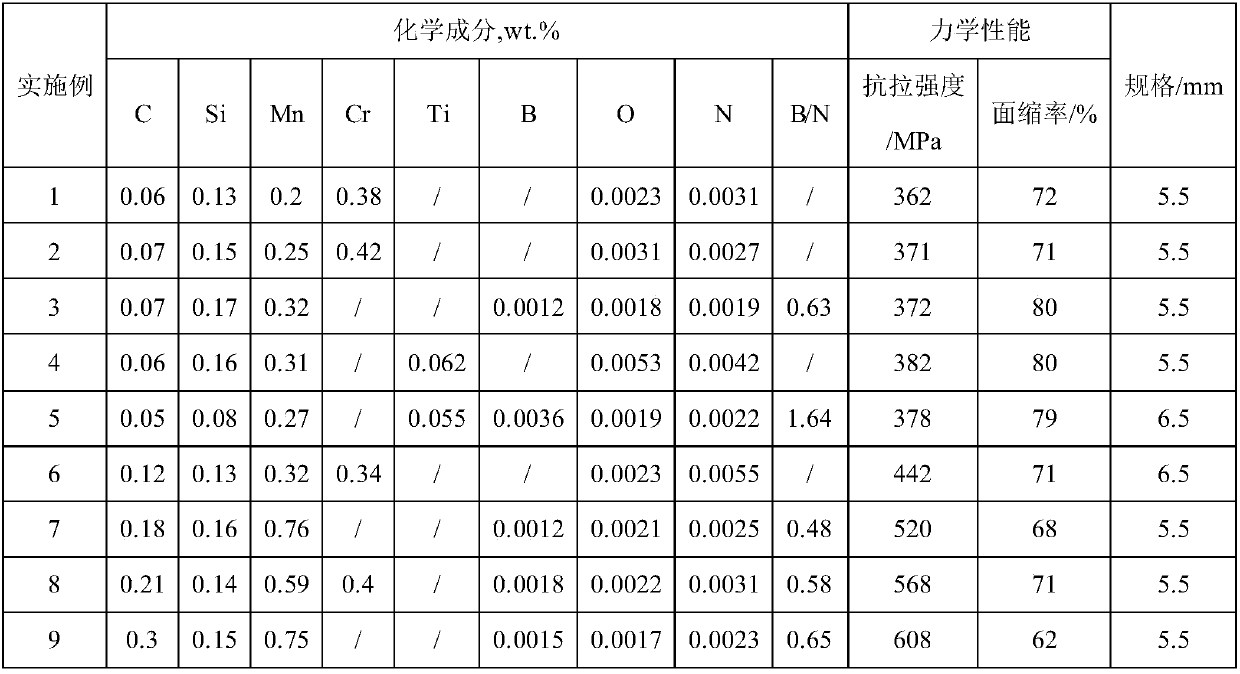

Examples

Embodiment 1 and 2

[0016] Examples 1 and 2: After continuous casting, hot charging and hot delivery are adopted, the starting rolling temperature is controlled to be 905°C, the rough and intermediate rolling is rolled without temperature control, the spinning temperature is 908°C, and the speed of the roller table is controlled to 0.3m / s. When the fan is not turned on, the opening of the Jialing device is adjusted to 40%, and the heat preservation cover is fully opened.

Embodiment 3

[0017] Example 3: After continuous casting, the billet is partially ground and rolled three days later. The starting rolling temperature is controlled at 925°C. The rough and medium rolling is rolled without temperature control. The spinning temperature is 912°C and the roller table speed is controlled. 0.35m / s, turn on the first fan, the air volume of the fan is 100%, the opening of the Jialing device is adjusted to 40%, and the insulation cover is fully opened.

Embodiment 4 and 5

[0018] Examples 4 and 5: After continuous casting, the billet is fully ground, and rolling is carried out three days later. The starting rolling temperature is controlled at 925°C. The rough and medium rolling is rolled without temperature control. The spinning temperature is 915°C. The speed control is 0.30m / s, the first two fans are turned on, and the air volume of the fans is 50%, the opening of the Jialing device is adjusted to 40%, and the insulation cover is fully opened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com