Process and plant for building tyres for vehicle wheels

A technology of tires and structures, applied in the direction of tires, applications, household appliances, etc., can solve problems such as negative impact on productivity, overall management problems of manufacturing systems, and productivity limitations, so as to achieve high performance quality, eliminate technical flexibility and/or productivity constraints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

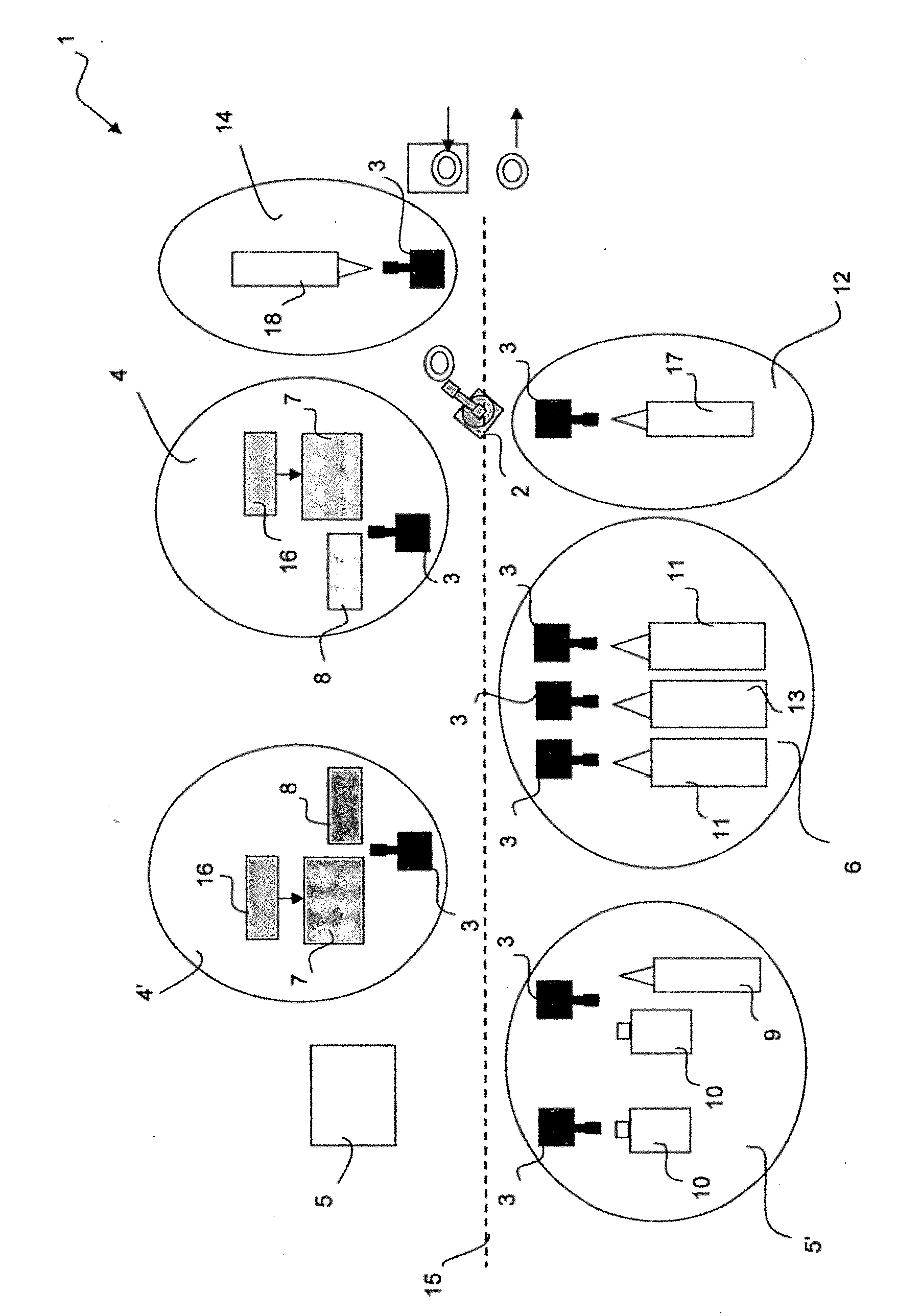

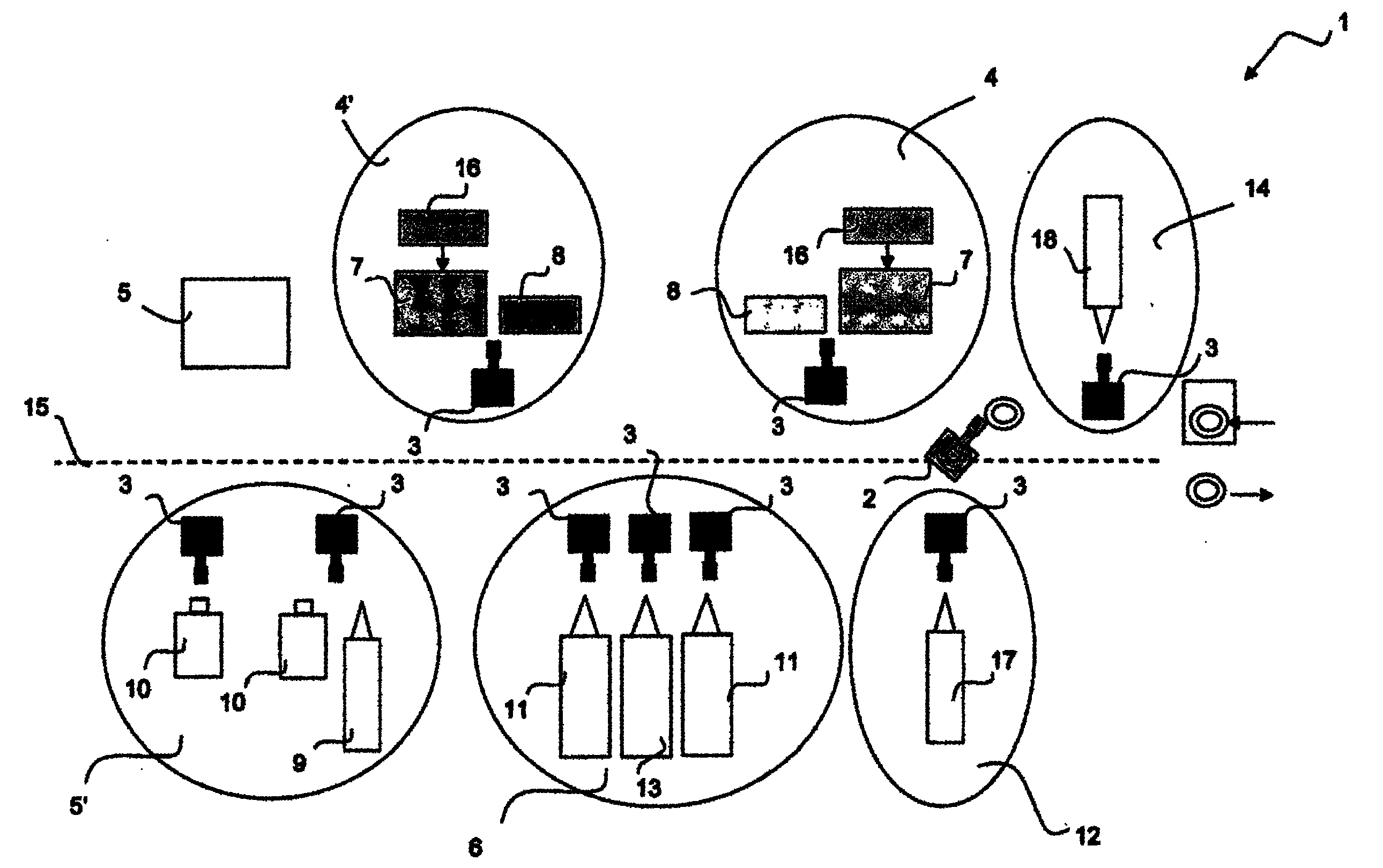

[0108] With reference to this figure, reference numeral 1 generally designates a building line of an apparatus for building tires for vehicle wheels according to the invention. The tires to be built are of at least two different models. These models may differ in size, structural components and / or unit components.

[0109] The building line 1 of the plant comprises a plurality of work stations 4, 4', 5, 5', 6, 12, 14, each of which is adapted to build at least one of each tire by assembling at least one unit component. a structural component. According to the definitions given above, the workstations 4, 4', 5, 5', 6, 12 and 14 are arranged according to a sequential series.

[0110] The construction line 1 of the system also comprises at least one handling device 3 for processing the respective forming support associated with each work station 4, 4', 5, 5', 6, 12, 14 on the tire being processed. Each processing means 3 is adapted to cooperate with a respective workstation 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com