Method for preparing aluminum alloy by virtue of molten salt electrodeoxidation-ingot metallurgy

A molten salt electro-deoxidation and aluminum alloy technology, applied in the field of electrolytic metallurgy, can solve the problems of alloy powder molten salt inclusion, complex process and equipment, large loss of active metal, etc., and achieves reduced element segregation, good development prospects, and uniform composition distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

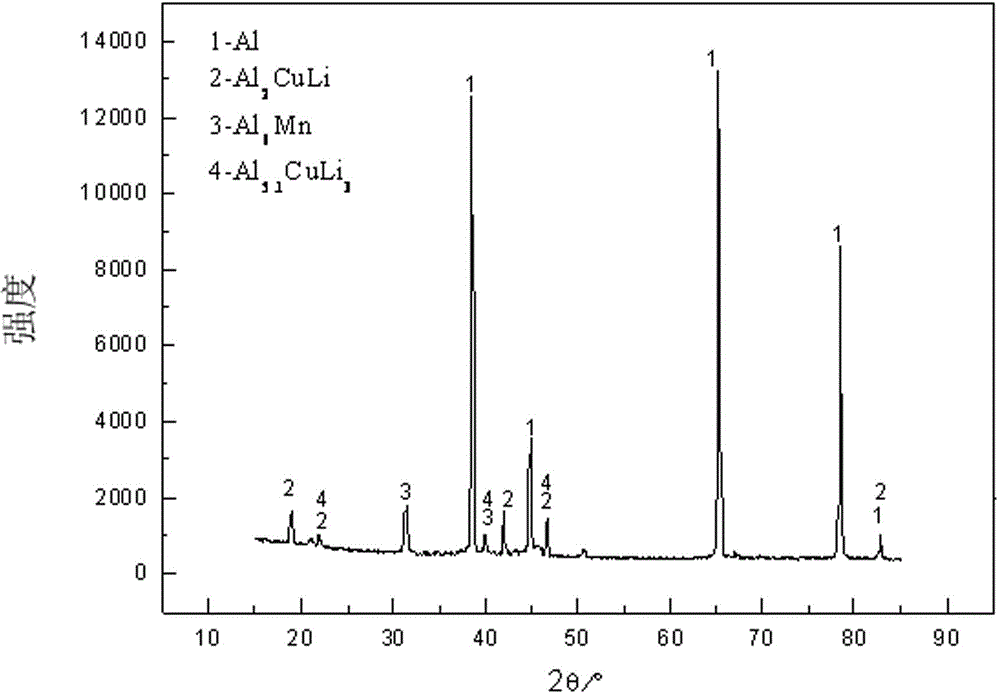

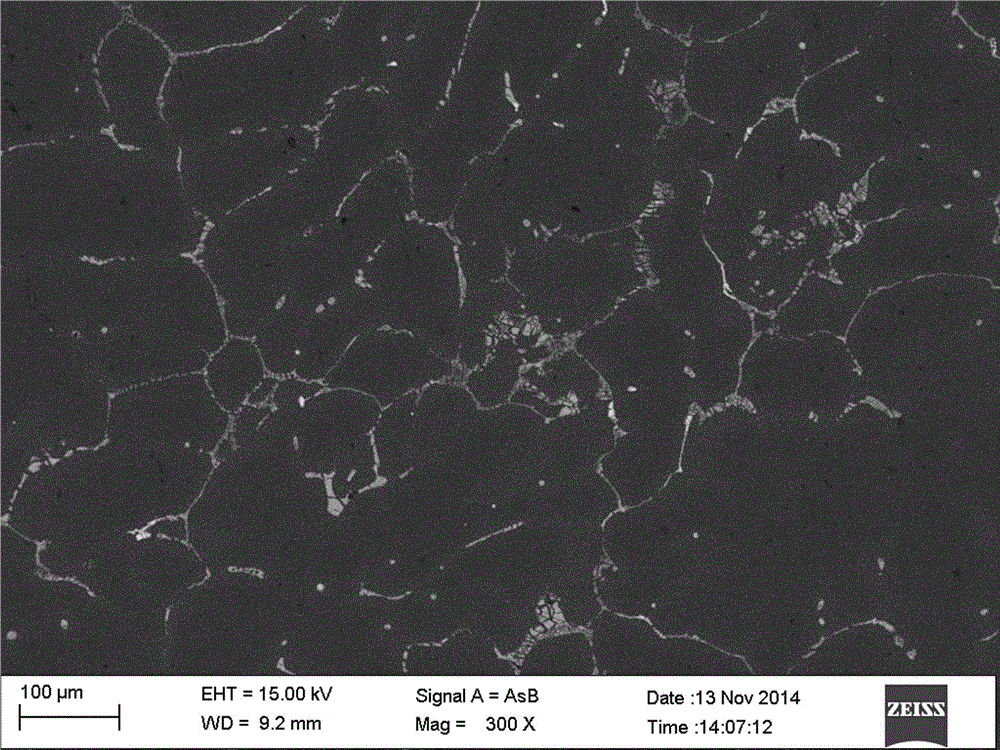

[0041] Preparation of 2297 Al-Li alloy:

[0042] Al powder, Cu powder and Li 2 The O powder is mixed evenly, and then compressed to obtain a mixed tablet; by weight percentage, the Al powder accounts for 90%, the Cu powder accounts for 5%, and the Li powder accounts for 5%. 2 O powder accounts for 5%;

[0043] Graphite is used as the anode, the mixed pressed tablet is used as the cathode, the cathode and the anode are placed in the molten salt electrolyte, and the electrolytic reduction is carried out by the molten salt electro-deoxidation method; the voltage during the electrolytic reduction is lower than the decomposition voltage of the molten salt electrolyte, and the electrolysis time is 5h After the electrolytic reduction is completed, the electrolytic product is separated from the molten salt electrolyte under the protection of an inert gas, and the temperature of the electrolytic product is lowered to normal temperature before being taken out; the molten salt electroly...

Embodiment 2

[0048] Preparation of 2397 Al-Li alloy:

[0049] Preparation of mixed tablets: Al powder, Cu powder and Li 2 The O powder is mixed evenly, and then compressed to obtain a mixed tablet; by weight percentage, the Al powder accounts for 70%, the Cu powder accounts for 10%, and the Li powder accounts for 10%. 2 O powder accounts for 20%;

[0050] Graphite is used as the anode, the mixed pressed tablet is used as the cathode, the cathode and the anode are placed in the molten salt electrolyte, and the electrolytic reduction is carried out by the molten salt electro-deoxidation method; the voltage during the electrolytic reduction is lower than the decomposition voltage of the molten salt electrolyte, and the electrolysis time is 8h After the electrolytic reduction is completed, the electrolytic product is separated from the molten salt electrolyte under the protection of an inert gas, and the temperature of the electrolytic product is lowered to normal temperature before being tak...

Embodiment 3

[0055] Preparation of 2197 Al-Li alloy:

[0056] Preparation of mixed tablets: Al powder, Cu powder and Li 2 The O powder is mixed evenly, and then compressed to obtain a mixed tablet; by weight percentage, the Al powder accounts for 80%, the Cu powder accounts for 8%, and the Li powder accounts for 8%. 2 O powder accounts for 12%;

[0057] Graphite is used as the anode, the mixed pressed tablet is used as the cathode, the cathode and the anode are placed in the molten salt electrolyte, and the electrolytic reduction is carried out by the molten salt electro-deoxidation method; the voltage during the electrolytic reduction is lower than the decomposition voltage of the molten salt electrolyte, and the electrolysis time is 11h , after the electrolytic reduction is completed, the electrolysis product is separated from the molten salt electrolyte under the protection of an inert gas, and the temperature of the electrolysis product is lowered to normal temperature and then taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com