Composite powder for high gravity alloy and preparation method thereof

A composite powder, high specific gravity technology, applied in coatings, jewelry, etc., can solve the problems of difficult large-scale production, poor composition uniformity, impurity reduction performance, etc., and achieve the effect of easy operation, improved mechanical properties, and uniform composition distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] A method for preparing composite powder for high specific gravity alloys, the method comprising the following steps:

[0065] (1) Degrease and pickle the tungsten powder, place the tungsten powder in an alkaline solution at 20-80°C for ultrasonic treatment for 10-60 min, then remove the upper layer solution and wash it with deionized water until it is neutral. The final powder was placed in an acidic solution at 20-80 °C for 10-60 min, then the upper solution was removed, washed with deionized water until neutral, and dried in vacuum for later use.

[0066] The particle size of the tungsten powder is 0.5-15 μm.

[0067] The tungsten powder is in irregular shape and / or spherical shape, such as irregular shape, spherical shape or a combination of irregular shape and spherical shape.

[0068] The components and concentrations thereof included in the alkaline solution in the degreasing process of the tungsten powder are as follows:

[0069] Sodium hydroxide 50~100 g / L

...

Embodiment 1

[0099] Example 1: Composite powder for nickel-iron alloy electroplating solution for intermittent electroplating of high specific gravity alloys

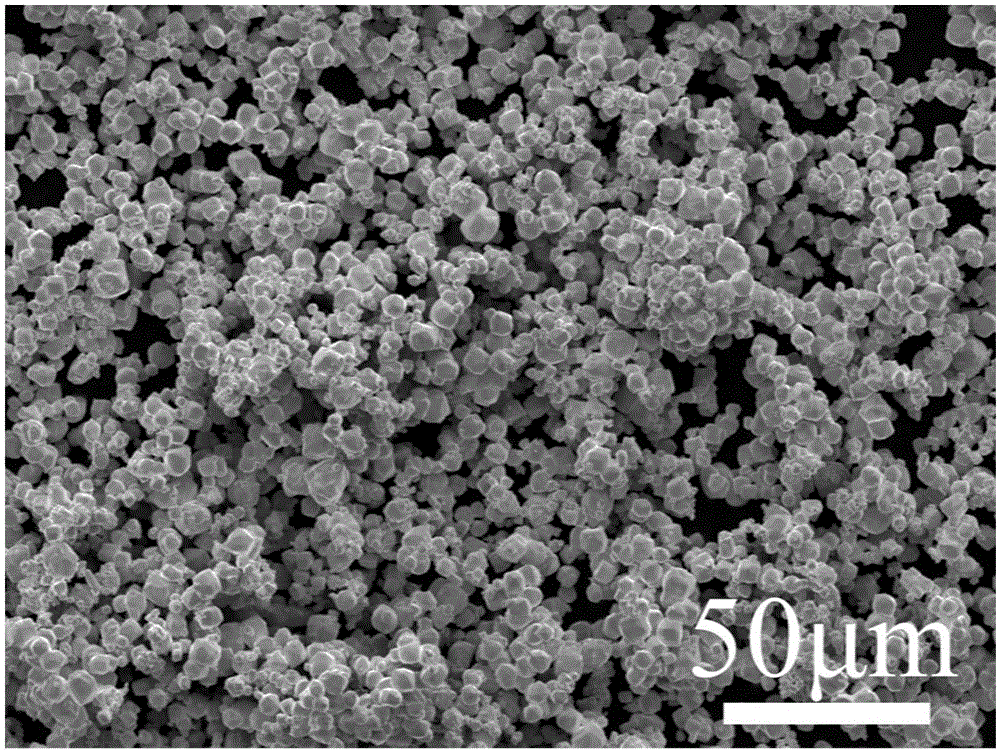

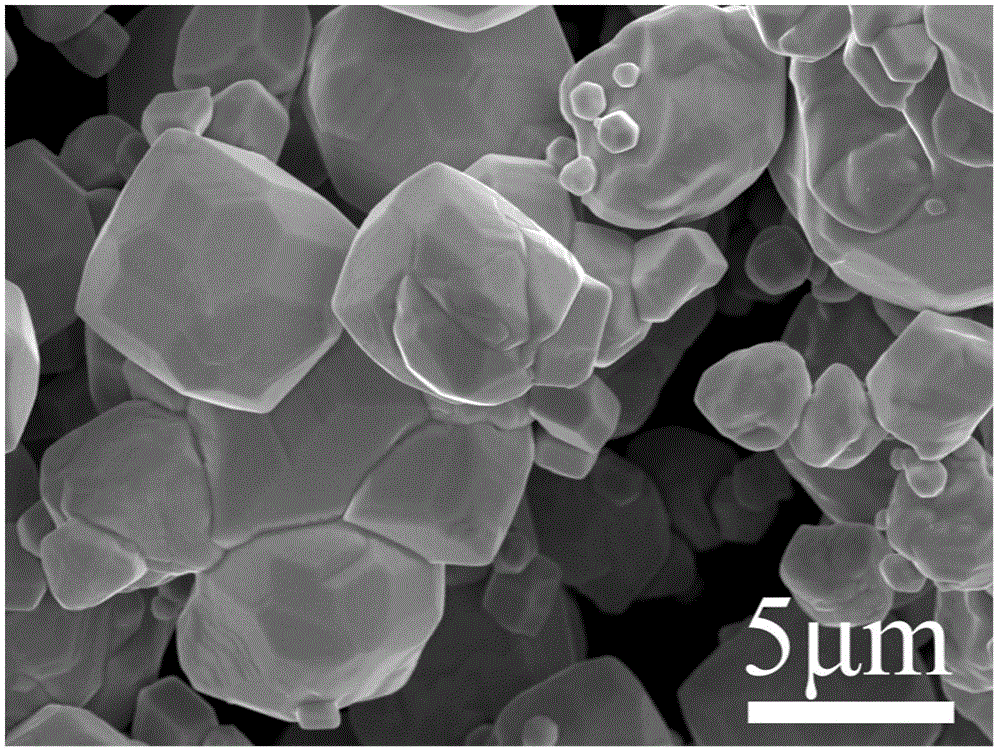

[0100] (1) Irregularly shaped tungsten powder with an average particle size of 4-6 μm ( figure 1 and figure 2 ) in an alkaline solution (degreasing solution) at 50°C for 30 minutes, and the alkaline solution includes: sodium hydroxide 100 g / L, sodium carbonate 10 g / L, trisodium phosphate 20 g / L, twelve Sodium alkyl sulfonate 1 g / L, then remove the upper layer solution, and wash it with deionized water to neutrality, then place it in an acidic solution at 20 °C for 30 min, wherein the acidic solution includes concentrated sulfuric acid 100 g / L, Then remove the upper layer solution and wash the tungsten powder to neutrality, and dry it in vacuum for later use. (2) Add the tungsten powder treated in step (1) into the iron-nickel alloy electroplating solution, wherein the dosage of tungsten powder is 13 g / L, and the plating solution ...

Embodiment 2

[0101] Example 2: Composite powder for nickel-iron alloy electroplating solution for intermittent electroplating of high specific gravity alloys

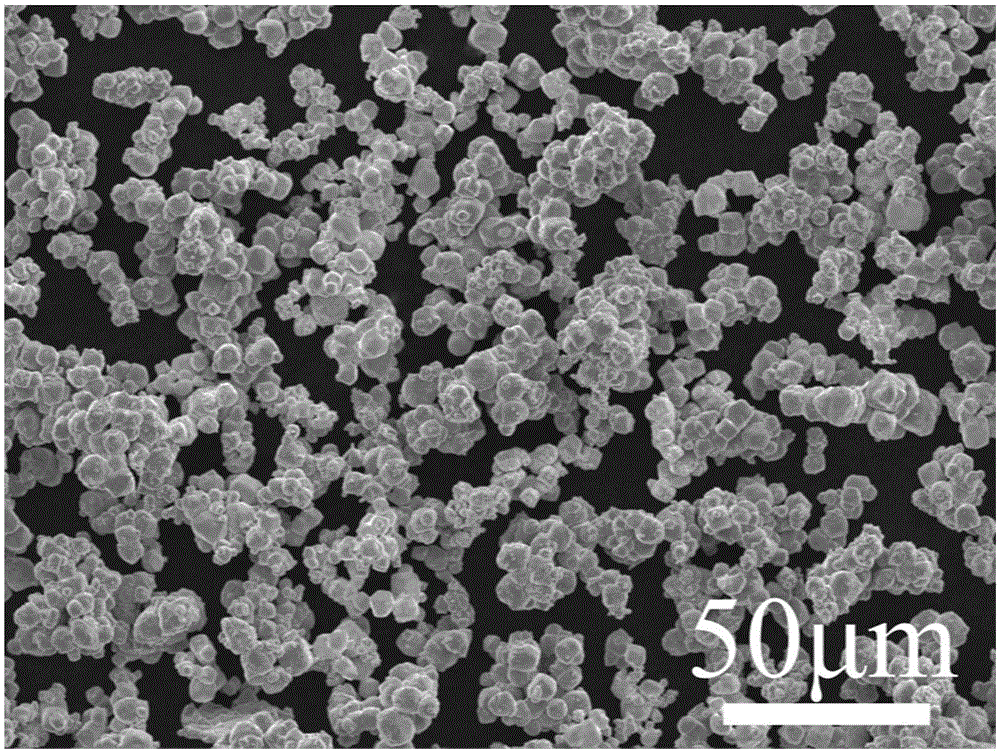

[0102] (1) Put spherical tungsten powder with an average particle size of 4-6 μm in an alkaline solution (degreasing solution) at 80°C for 60 minutes, wherein the alkaline solution includes: sodium hydroxide 100 g / L, carbonic acid Sodium 50 g / L, trisodium phosphate 60 g / L, sodium dodecylsulfonate 5 g / L, then remove the upper layer solution, and wash it with deionized water until neutral, then put it in an acidic solution at 80°C Sonicate for 60 min, in which the acidic solution includes concentrated sulfuric acid 200 g / L, then remove the upper layer solution and wash the tungsten powder to neutrality, and vacuum dry it for later use. (2) Add the tungsten powder treated in step (1) into the nickel-iron alloy electroplating solution, wherein the dosage of tungsten powder is 12 g / L, and the plating solution includes: nickel sulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com