Super-hard self-lubricating diamond/diamond-like composite laminated coating material and preparation method thereof

A multi-layer material, self-lubricating technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of wear resistance limitation, no diamond, large residual stress of diamond film, etc. Good anti-wear and wear-resistant properties, excellent self-lubricating anti-friction and wear properties, precise and controllable synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] WC-6%Co is selected as the coating substrate, and the cemented carbide is made into the international standard shape SNGN1204 08 0.3×30° (12.7×12.7×4.76mm) blade, and the process described in (2) is used for cleaning and pretreatment After that, use a drying oven to dry for later use.

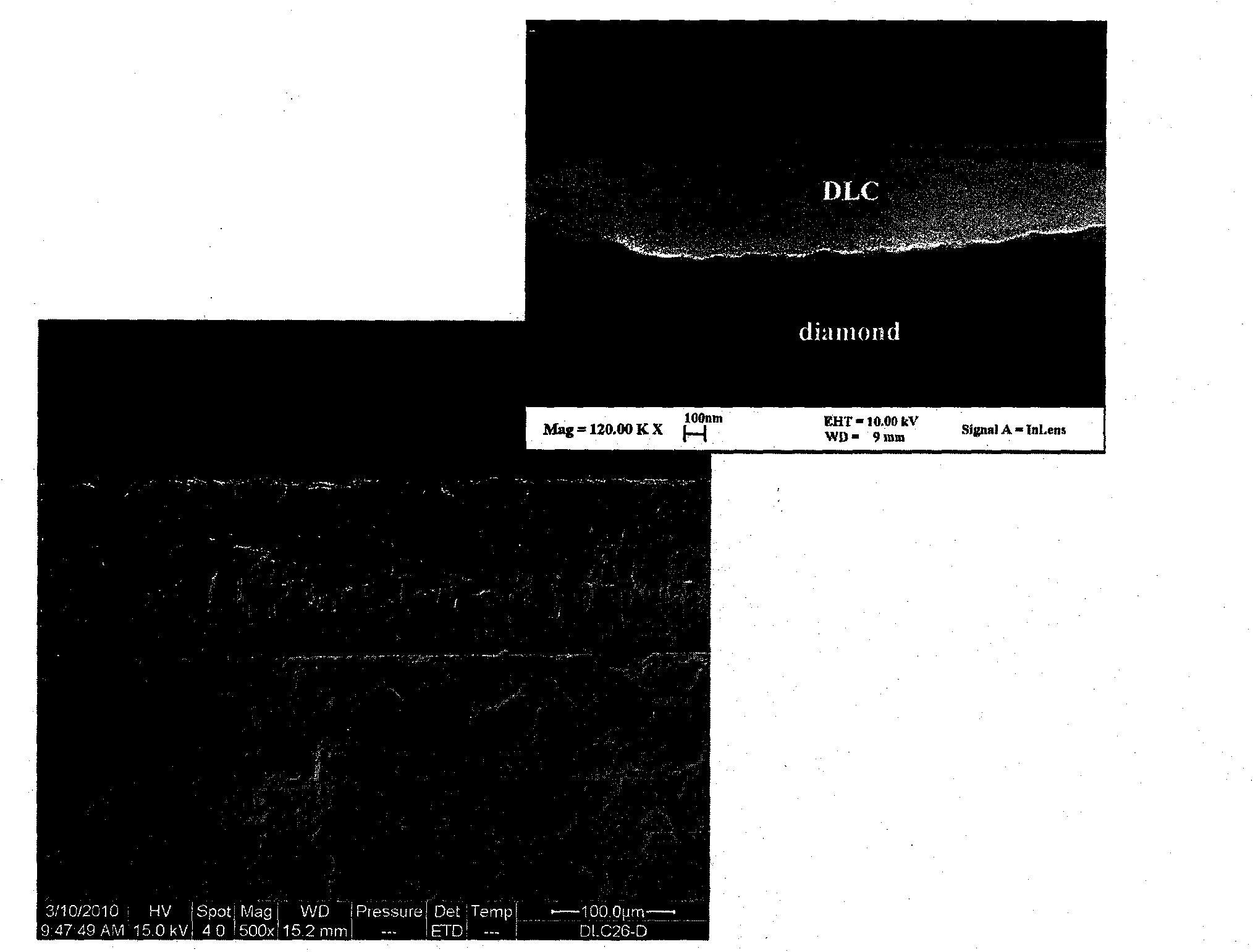

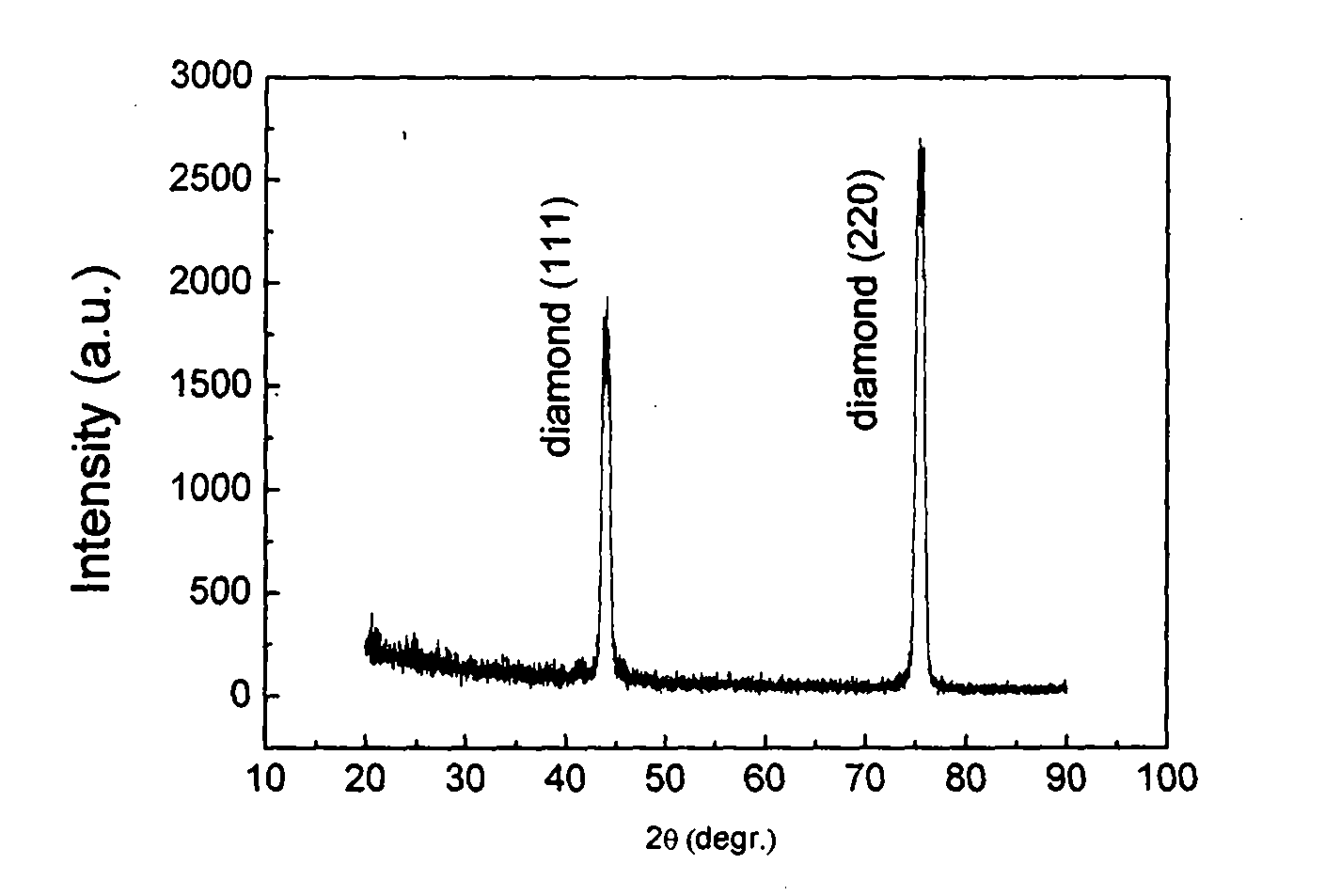

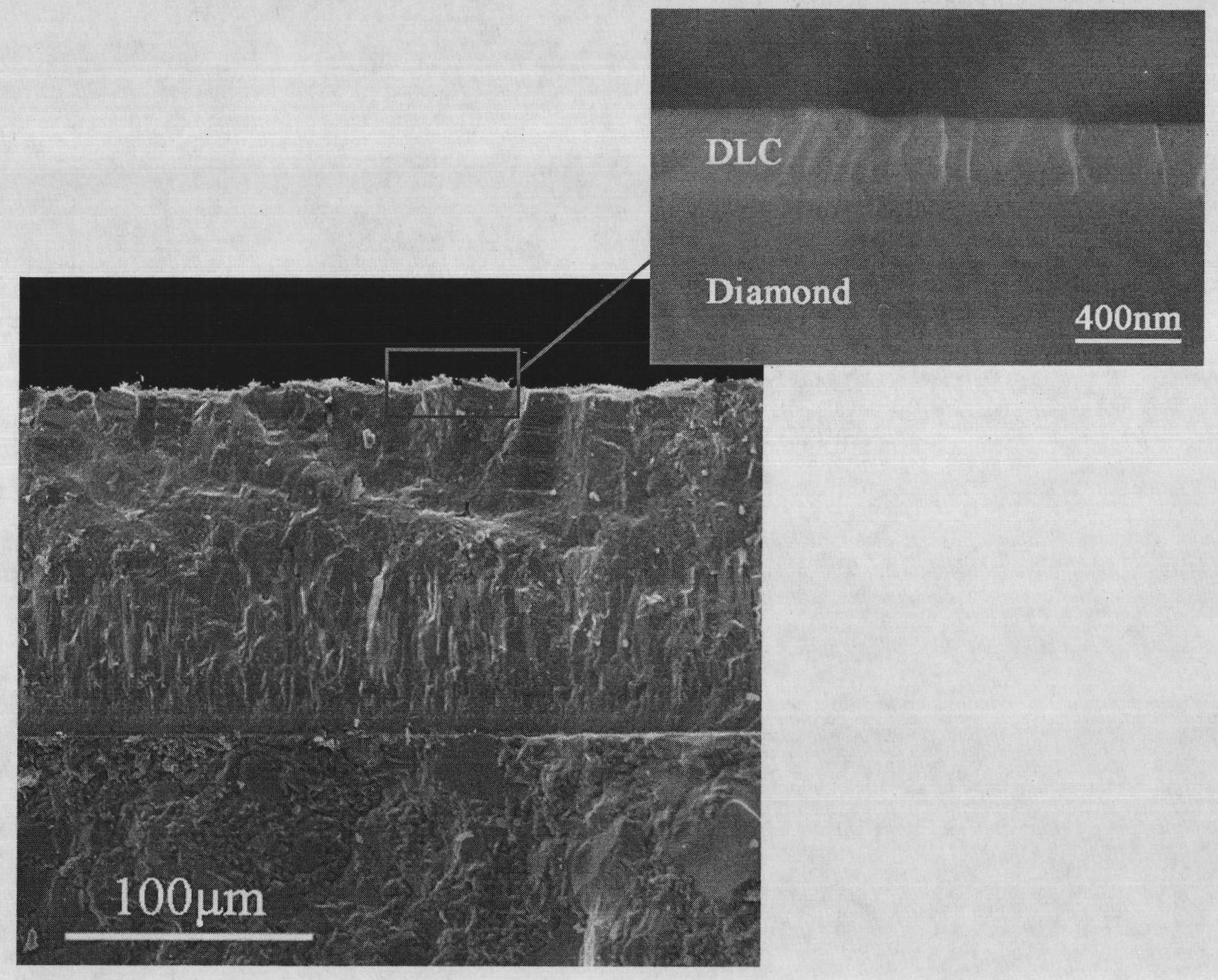

[0032] Put the pretreated cemented carbide substrate into the vacuum chamber of the hot-wire CVD deposition device. The distance between the substrate and the hot-wire is 25mm. First, tetramethylsilane and hydrogen are used as reaction gases, and SiC with a thickness of about 10μm is deposited as a transition layer. Among them, the volume fraction of tetramethylsilane is 0.1Vol.%, the total pressure of the working gas is 0.5kPa, the gas flow is 2000sccm, the temperature of the tungsten wire is 1900℃, and the temperature of the substrate is 780℃; subsequently, methane and hydrogen are used as reaction gases to deposit the diamond film. Fraction 1.5Vol.%, working gas pressure 3.0kPa, gas flow...

Embodiment 2

[0037] A stainless steel with a size of 60mm×50mm is selected as the coating substrate, and after cleaning and pretreatment using the process described in (2) above, it is dried in a drying oven for use.

[0038] Put the pretreated substrate into the vacuum chamber of the hot filament CVD deposition device. The distance between the substrate and the hot filament is 25mm. First, use tetramethylsilane, nitrogen and hydrogen as reactive gases, and deposit SiCN with a thickness of 25μm as the transition layer. The volume fraction of methylsilane is 0.1Vol.%, the volume fraction of nitrogen is 0.15Vol.%, the total pressure of working gas is 0.6kPa, the gas flow is 2000sccm, the temperature of the tungsten wire is 1900℃, and the temperature of the substrate is 400℃; subsequently, methane and hydrogen are used as reaction gases for deposition Diamond, methane volume fraction 1.5Vol.%, working gas pressure 3.0kPa, gas flow 300sccm, tungsten wire temperature 2100℃, substrate temperature 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com