Combined treatment method for ship ballast water

A technology of ship ballast water and combined treatment, applied in the field of water treatment, can solve the problems of decreasing killing rate and effect on effectiveness, and achieve the effect of less floor space, safe operation and strong sterilization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples describe the present invention in more detail:

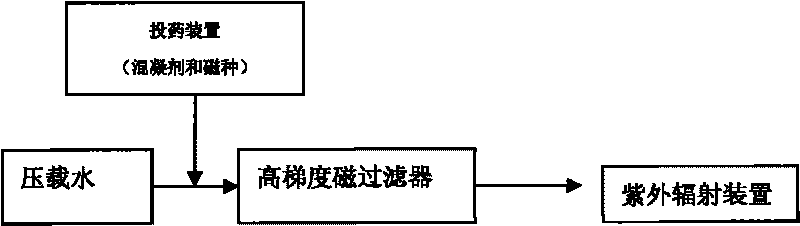

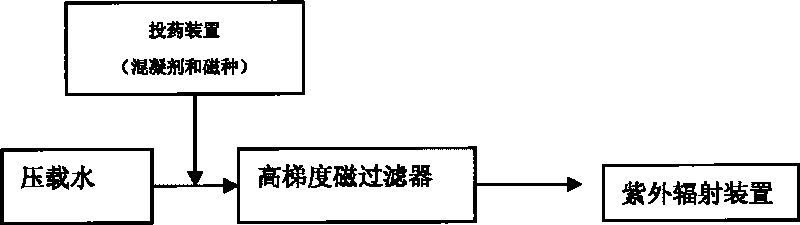

[0022] The treatment method of the ballast water of the present embodiment is realized through the following steps successively:

[0023] First of all, according to the water quality of the ballast water, a certain amount of coagulant and ironmaking furnace dust can be added to pretreat the ship’s ballast water. The coagulant is ferric chloride, and the dosage is 5-100mg / L. The dosage of iron furnace dust is 100mg / L-300mg / L, and the mixing method is mixed by static mixer.

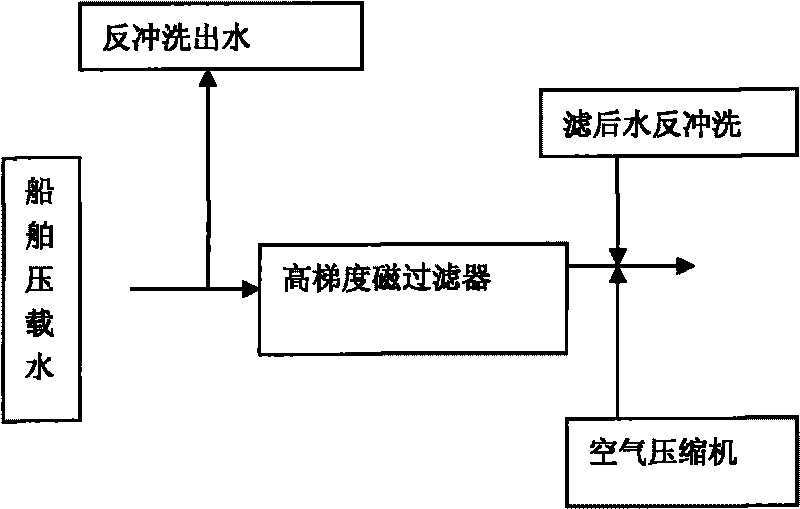

[0024] The pretreated ballast water is filtered through a high-gradient magnetic filter. The high-gradient magnetic filter is composed of an excitation coil, a magnetic yoke iron, a cylinder with steel wool added, and a wiring device. The high-gradient magnetic separator using steel wool matrix can separate weakly magnetic fine particles with low magnetic susceptibility and small volume that cannot be separated by general magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com