Method for manufacturing WS2 solid lubrication film

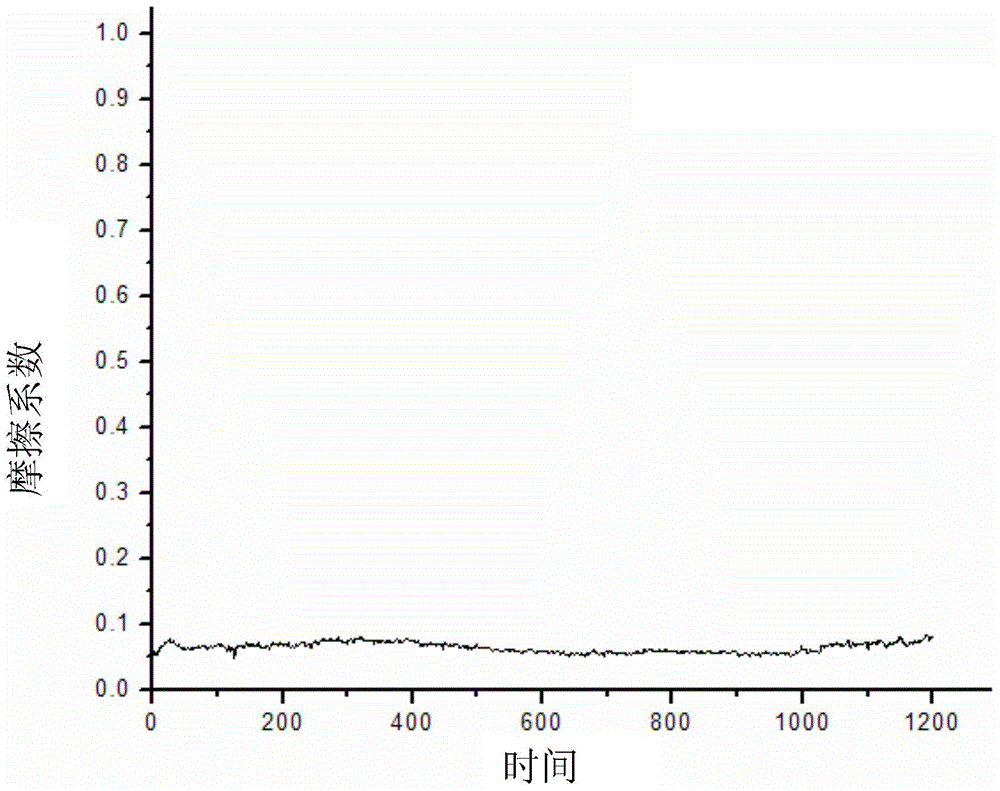

A technology of solid lubrication and manufacturing method, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems that cannot fully meet the requirements of long-life solid lubrication equipment and equipment, the influence of wear resistance of film layers, and the surface of film layers. Large roughness and other problems, to achieve the effect of short preparation time, long wear life and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

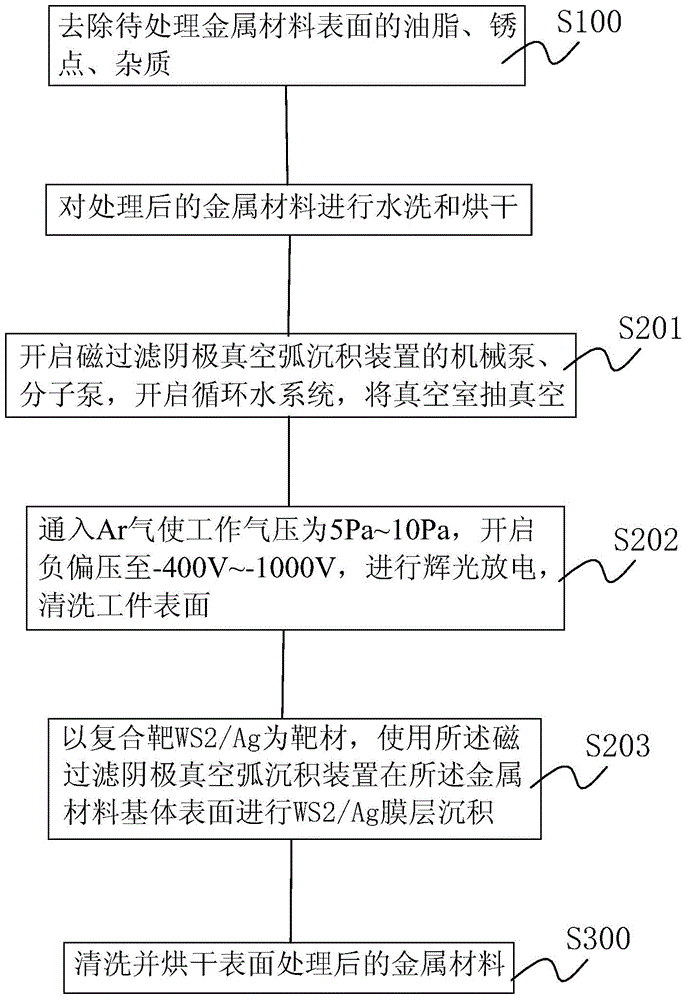

[0052] 1) Put the sample to be processed into the magnetic filtration equipment, and use WS 2 / Ag composite target;

[0053] 2) Turn on the mechanical pump and molecular pump, turn on the circulating water system, and evacuate to 6.0×10 -4 Pa, start process;

[0054] 3) Introduce Ar gas to make the working pressure 5Pa ~ 10Pa, turn on the negative bias to -400V ~ -1000V, perform glow discharge, and clean the surface of the workpiece;

[0055] 4) The specific control parameters are: the arc voltage is 20V~36V, the negative bias voltage is -100V~-800V, and the arc current is 90A~100A. The duty ratio is 50-90%, and the deposition time is 1h. The diameter of the magnetic filter tube is 200mm, the arc of the elbow is 0°, and the magnetic field deflection current is 1.6A~2.2A.

Embodiment 2

[0057] 1) Put the sample to be processed into the magnetic filtration equipment, and use WS 2 / Ag composite target;

[0058] 2) Turn on the mechanical pump and molecular pump, turn on the circulating water system, and evacuate to 6.0×10 -4 Pa, start process;

[0059] 3) Introduce Ar gas to make the working pressure 5Pa ~ 10Pa, turn on the negative bias to -400V ~ -1000V, perform glow discharge, and clean the surface of the workpiece;

[0060] 4) The specific control parameters are: the arc voltage is 20V~36V, the negative bias voltage is -100V~-800V, and the arc current is 90A~100A. The duty ratio is 50-90%, and the deposition time is 1h. The diameter of the magnetic filter tube is 200mm, the arc of the elbow is 90°, and the magnetic field deflection current is 1.6A~2.2A.

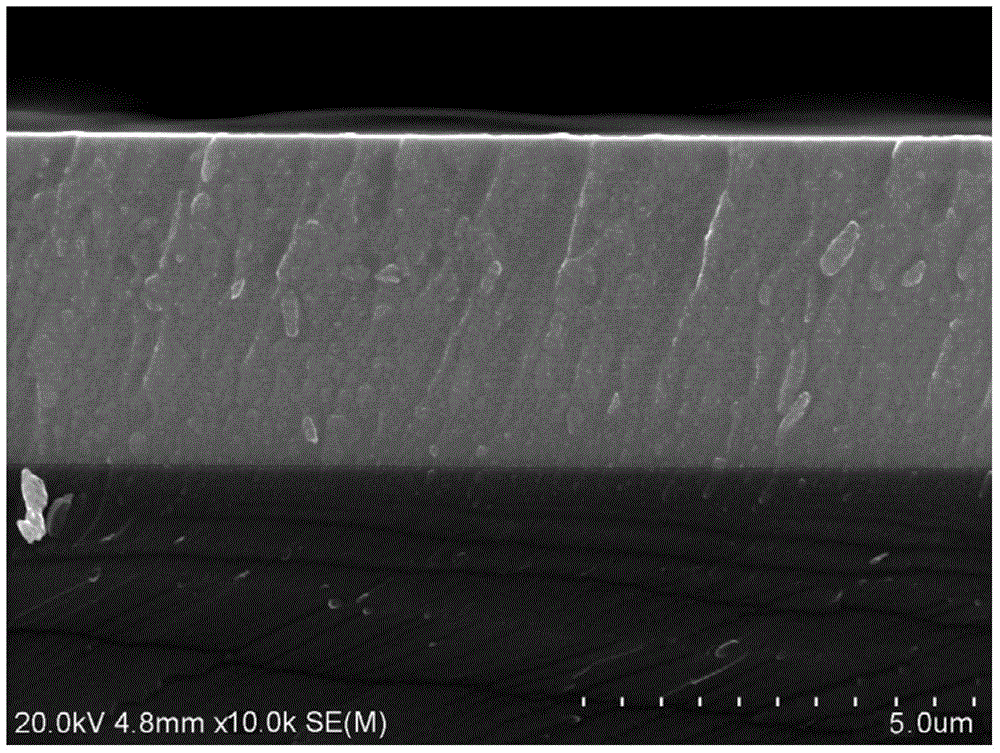

[0061] The invention controls the growth of the film by adjusting parameters such as arc voltage, arc current, negative pressure, and duty cycle to optimize the structure of the film and improve the fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com