Method for producing hydrophobic DLC coating layer

A coating and hydrophobic technology, which is applied in the field of preparation of hydrophobic DLC coatings, to achieve the effect of improving the binding force, improving the uniformity of the film layer, and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

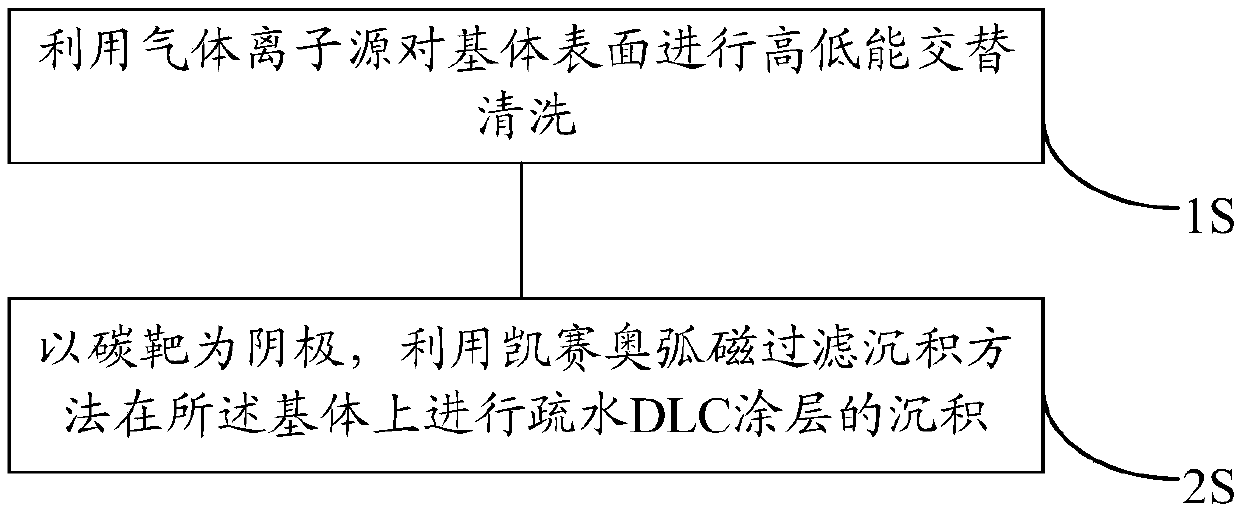

[0060] The preparation method of the hydrophobic DLC coating of the present application comprises the following steps:

[0061] The Kaufman ion source is used to alternately clean the surface of the substrate with high and low energy, and polish or etch the surface of the substrate to obtain a substrate surface with a roughness of 0.01-0.1 microns. Among them, the energy of the Kaufman ion source is 1-3000eV, and the beam intensity is 1-500mA.

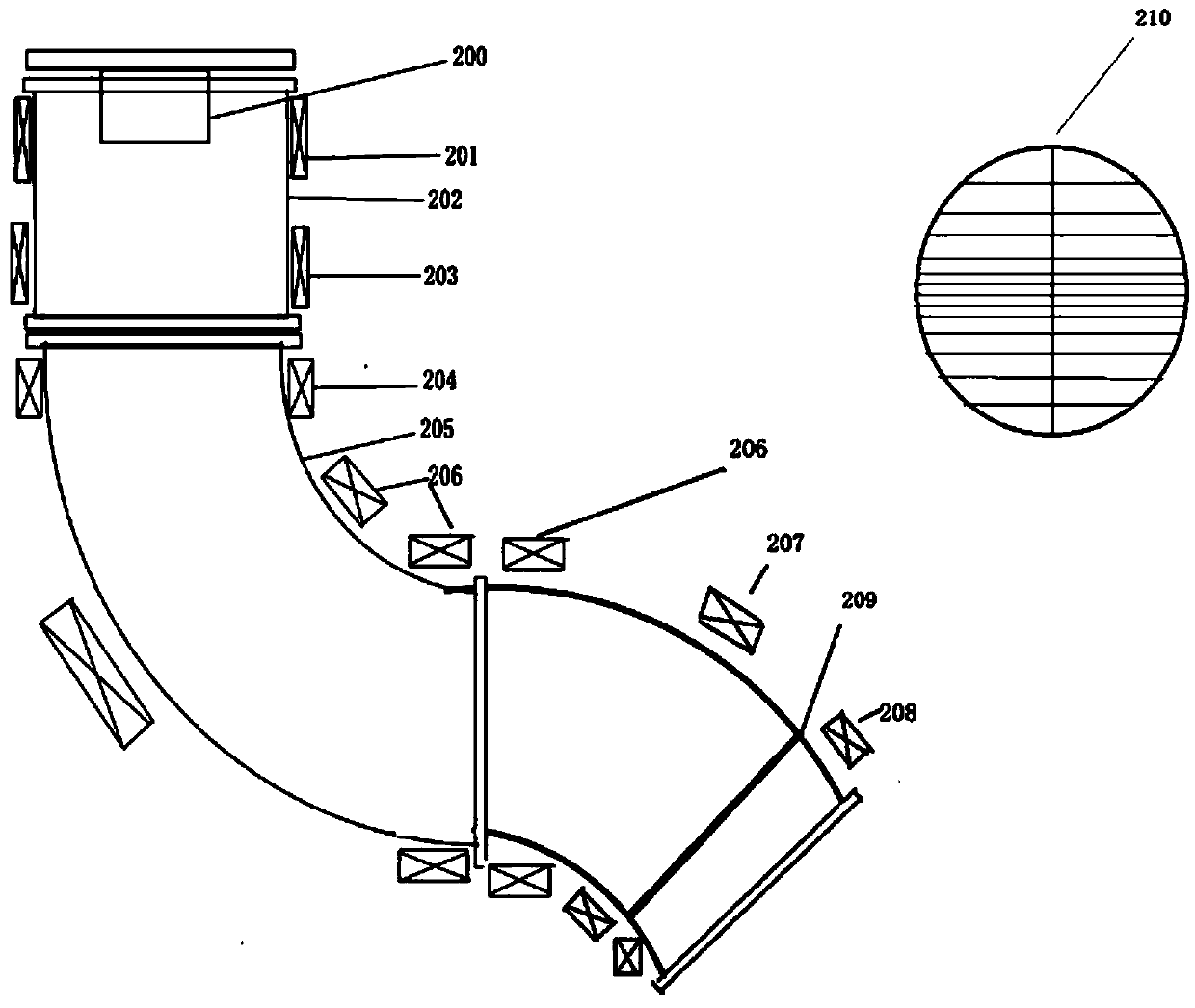

[0062] With the carbon target as the cathode, the carbon ions generated by the carbon target pass through the first strong pulse line package, the suppression line package and the second strong pulse line package, the middle line package, and the third strong pulse line set on the magnetic filter elbow in sequence. package, high-power pulse grid and high-pulse focused line package, and then deposit a hydrophobic DLC film layer with a self-organized concave-convex structure on the substrate.

[0063] Deposition process: set the arcing ...

Embodiment 1

[0068] 1S: Use the Kaufmann ion source to clean the substrate with high energy (1500-2000V), and use the Kaufmann ion source to clean the substrate with low energy (100-500V);

[0069] 2S: Use the carbon target as the cathode, set the arcing current to 100A, the high-power pulse bias voltage is the highest voltage of 12kv, the pulse width is 5ms, and the pulse frequency is 200Hz; the DC bias voltage is 300V, the duty cycle is 80%; the deposition time is 40 minutes .

[0070] The magnetic field parameters of each wire package are as follows:

[0071] 201: frequency 18Hz, current 30A;

[0072] 203: frequency 50Hz, current 5A;

[0073] 204: frequency 80Hz, current 20A;

[0074] 206: current 3A;

[0075] 207: frequency 20Hz, current 18A;

[0076] 208: frequency 150Hz, current 100A;

[0077] 209: the voltage is -20V, and the frequency is 10Hz.

Embodiment 2

[0079] 1S: Use the Kaufmann ion source to clean the substrate with high energy (2000-2500V), and use the Kaufmann ion source to clean the substrate with low energy (100-300V);

[0080] 2S: carbon target as cathode, arcing current 100A, high-power pulse bias voltage up to 8kv, pulse width 3ms, pulse frequency 10Hz; DC bias voltage 600V, duty cycle 50%; deposition time 50 minutes.

[0081] The magnetic field parameters of each wire package are as follows:

[0082] 201: frequency 50Hz, current 20A;

[0083] 203: frequency 50Hz, current 3A;

[0084] 204: frequency 80Hz, current 20A;

[0085] 206: current 3A;

[0086] 207: frequency 30Hz, current 15A;

[0087] 208: frequency 80Hz, current 20A;

[0088] 209: the voltage is -10V, and the frequency is 5Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com