Multilayered high-temperature-resistant Ti/Zr codoped diamond-like coating and preparation method thereof

A diamond coating and co-doping technology, applied in the field of coating deposition, can solve the problems of poor thermal stability, low bonding strength of film base, high internal stress of diamond-like coating, reduce internal stress, prevent peeling and cracking, The effect of reducing the accumulation of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

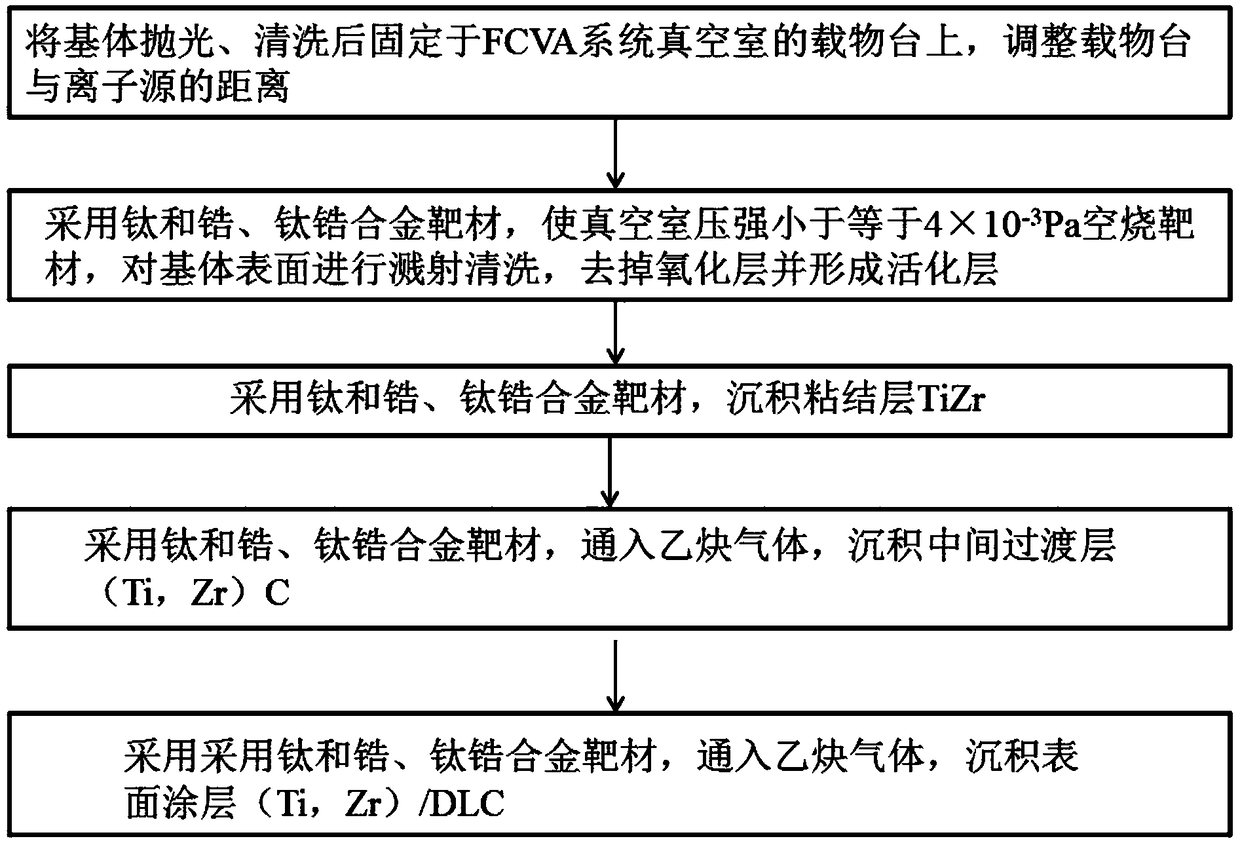

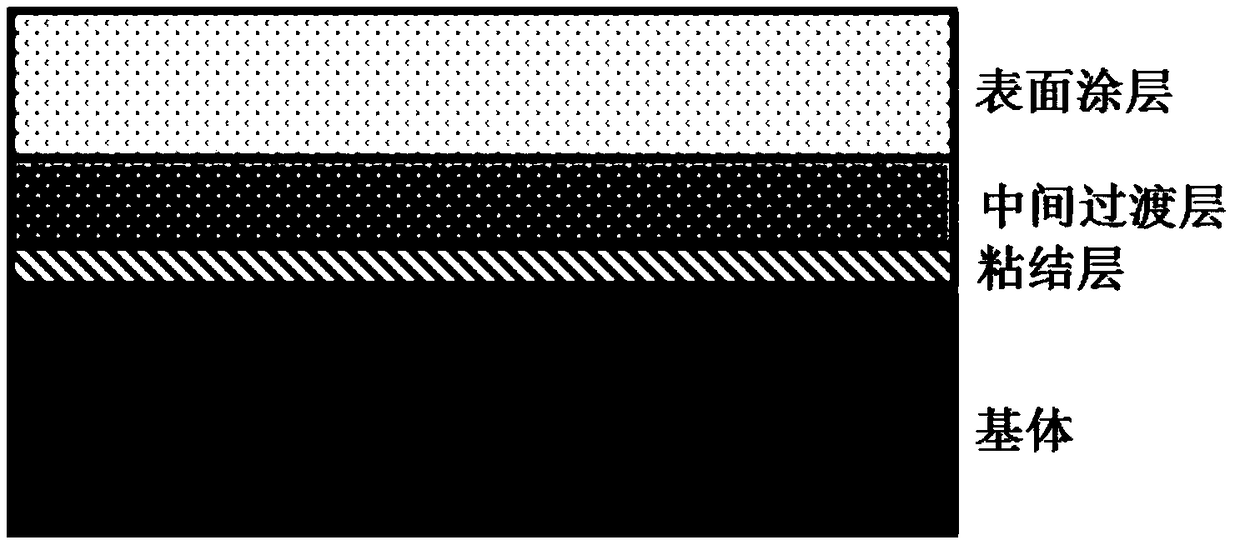

[0055] Another aspect of the present invention provides a method for preparing a multilayer high temperature resistant Ti / Zr co-doped diamond-like coating, the specific steps are as follows:

[0056] (a) Pretreatment of the substrate:

[0057] Use sandpaper and polishing cloth to polish the substrate to a mirror structure, and ultrasonically clean it in acetone and absolute ethanol for 5 to 15 minutes, dry it and place it on the stage of the magnetic filter cathodic vacuum arc deposition system, facing the ion source , adjust the distance between the stage and the ion source to be 5-40cm;

[0058] Preferably, the distance between the stage and the ion source is adjusted to be 15-40 cm;

[0059] (b) Sputter cleaning of substrate surface:

[0060] The magnetic filter cathodic vacuum arc deposition technology is adopted, and 99.9% titanium, zirconium, and titanium zirconium alloy are used as targets. The magnetic filter cathodic vacuum arc deposition system can work at the same...

Embodiment 1

[0080] (a) Using a magnetic filter cathodic vacuum arc deposition system, keep the vacuum chamber pressure less than or equal to 4×10 before starting the coating -3 Pa, using titanium-zirconium alloy (Ti:Zr=3:1) as the target material, turn off the gas flow, turn on the arc power supply, adjust the arc starting current to 90A, the elbow magnetic field current to 4.0A, the negative bias to -900V, and the duty cycle The ratio is 90%, and the surface of the substrate is sputtered and cleaned for 2 minutes;

[0081] (b) On the basis of step (a), adjust the negative bias voltage to -300V, the duty cycle to 80%, and deposit the TiZr bonding layer on the surface of the substrate after cleaning, and the deposition time is 5 minutes;

[0082](c) On the basis of step (b), feed acetylene gas into the vacuum chamber, and adjust the gas feed rate to be 5sccm, 10sccm, 15sccm, 20sccm to deposit the intermediate transition layer successively, at the deposition of each gas feed rate The time ...

Embodiment 2

[0087] All the experimental parameters and experimental procedures in this example are exactly the same as those in Example 1, only the Ti:Zr=3:1 of the titanium-zirconium alloy target in Example 1 needs to be changed to Ti:Zr=4:1 / 5 :1 titanium-zirconium alloy target to obtain multi-layer high temperature resistant Ti / Zr co-doped diamond-like coating.

[0088] When the titanium-zirconium alloy target material Ti:Zr=4:1, the prepared Ti / Zr co-doped diamond-like coating was tested, and it was found that the thickness of the bonding layer TiZr was 0.4 μm, and the intermediate transition layer (Ti , Zr) The thickness of C is 0.6 μm, and the thickness of surface coating Ti / Zr co-doped diamond-like carbon coating is 1.1 μ m; The content of Ti in its surface coating Ti / Zr co-doped diamond-like coating is 5.53at .%, Zr content is 1.69at.%.

[0089] When the titanium-zirconium alloy target material Ti:Zr=5:1, the prepared Ti / Zr co-doped diamond-like coating was tested, and the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com