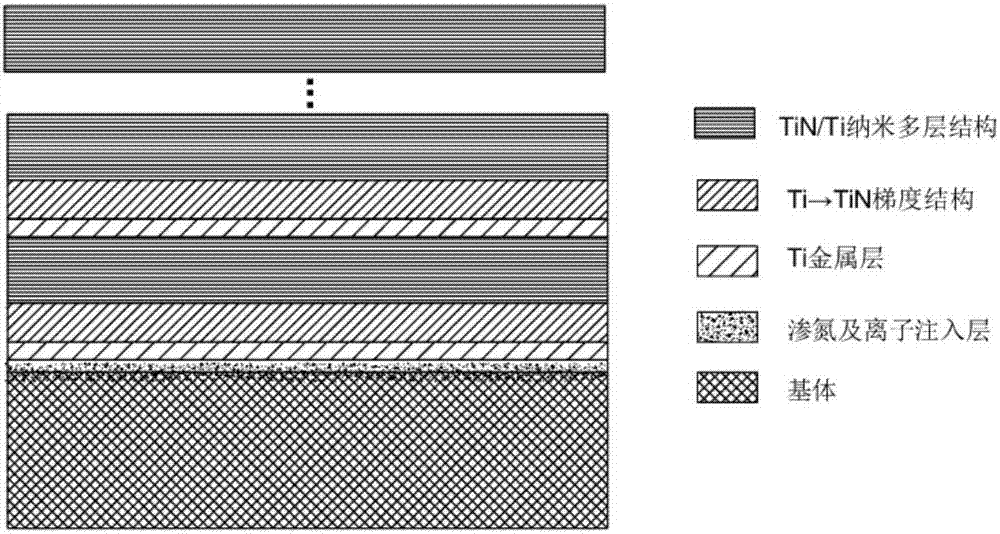

Nano multilayer gradient composite anti-erosion coating structure and preparation method thereof

A nano-multilayer, anti-erosion technology, applied in the coating, superimposed layer plating, metal material coating process and other directions, can solve the problem that the bonding force of the film base cannot meet the sand and dust erosion resistance, and achieve impact toughness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Polishing and cleaning of the substrate

[0036] Use 400-600, 800-1000, 1200 and 2000 mesh sandpaper in turn to rough and finely grind the TC4 substrate sample until there are no obvious horizontal and vertical grinding marks, and then use polishing flannelette and diamond polishing paste to polish the finely ground sample Process until the surface roughness of the sample reaches Ra=0.02±0.005 μm.

[0037] The polished substrate must be ultrasonically cleaned twice with absolute ethanol and acetone before clamping and coating, each time for 10 minutes, and quickly dried with high-purity nitrogen.

[0038] 2) surface nitriding treatment

[0039] The process of nitriding the surface of the substrate is as follows: using the glow plasma nitriding technology, the surface nitriding treatment of the substrate is carried out, and the nitriding gas is NH 3 , the glow voltage is 800V, the current is 13A, the vacuum in the furnace is 100Pa, the nitriding temperature is 400°C...

Embodiment 2

[0051] 1) Polishing and cleaning of the substrate

[0052] Use 400-600, 800-1000, 1200 and 2000 mesh sandpaper in sequence to rough and finely grind the TC4 matrix sample, and then use polishing flannelette and diamond polishing paste to polish the finely ground sample until the surface of the sample is rough The degree reaches Ra=0.02±0.005μm.

[0053] After polishing, the substrate must be ultrasonically cleaned with absolute ethanol and acetone for 10 minutes before clamping and coating, and then quickly dried with high-purity nitrogen.

[0054] 2) surface nitriding treatment

[0055] The process of nitriding the surface of the substrate is as follows: using the glow plasma nitriding technology, the surface nitriding treatment of the substrate is carried out, and the nitriding gas is NH 3 , the glow voltage is 800V, the current is 13A, the vacuum in the furnace is 100Pa, the nitriding temperature is 400°C, and the nitriding time is 1h.

[0056] 3) Preparation of "Embedde...

Embodiment 3

[0069] 1) Polishing and cleaning of the substrate

[0070] Use 400-600, 800-1000, 1200 and 2000 mesh sandpaper in sequence to rough and finely grind the TC4 matrix sample, and then use polishing flannelette and diamond polishing paste to polish the finely ground sample until the surface of the sample is rough The degree reaches Ra=0.02±0.005μm.

[0071] After polishing, the substrate must be ultrasonically cleaned with absolute ethanol and acetone for 10 minutes before clamping and coating, and then quickly dried with high-purity nitrogen.

[0072] 2) surface nitriding treatment

[0073] The process of nitriding the surface of the substrate is as follows: using the glow plasma nitriding technology, the surface nitriding treatment of the substrate is carried out, and the nitriding gas is NH 3 , the glow voltage is 800V, the current is 13A, the vacuum in the furnace is 100Pa, the nitriding temperature is 400°C, and the nitriding time is 1h.

[0074] 3) Preparation of "Embedde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rough surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com