Super-hydrophobic composite coating and preparation method thereof as well as application

A composite coating, super-hydrophobic technology, applied in the coating, metal material coating process, ion implantation plating and other directions, can solve the problem of poor hydrophobicity of the coating, and achieve the effect of prolonging the service life and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

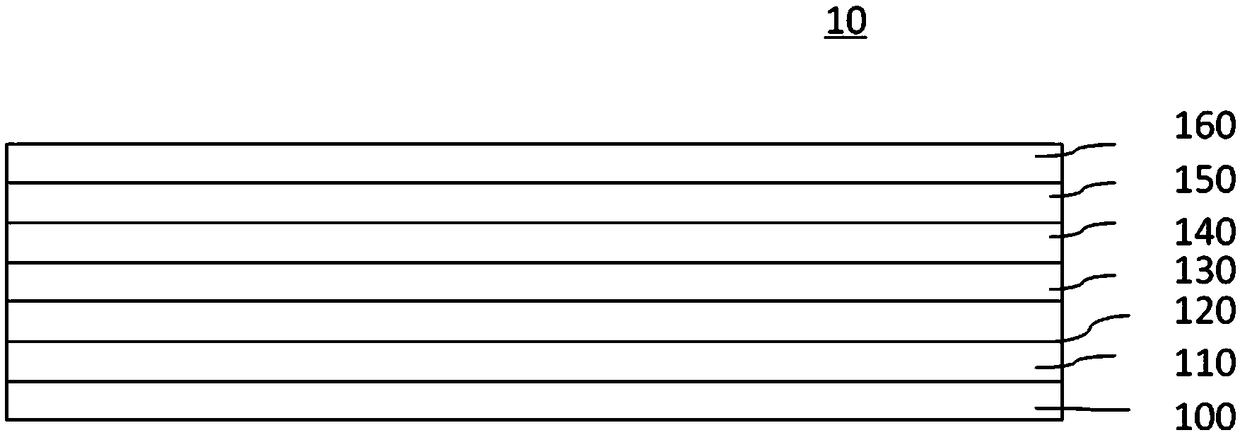

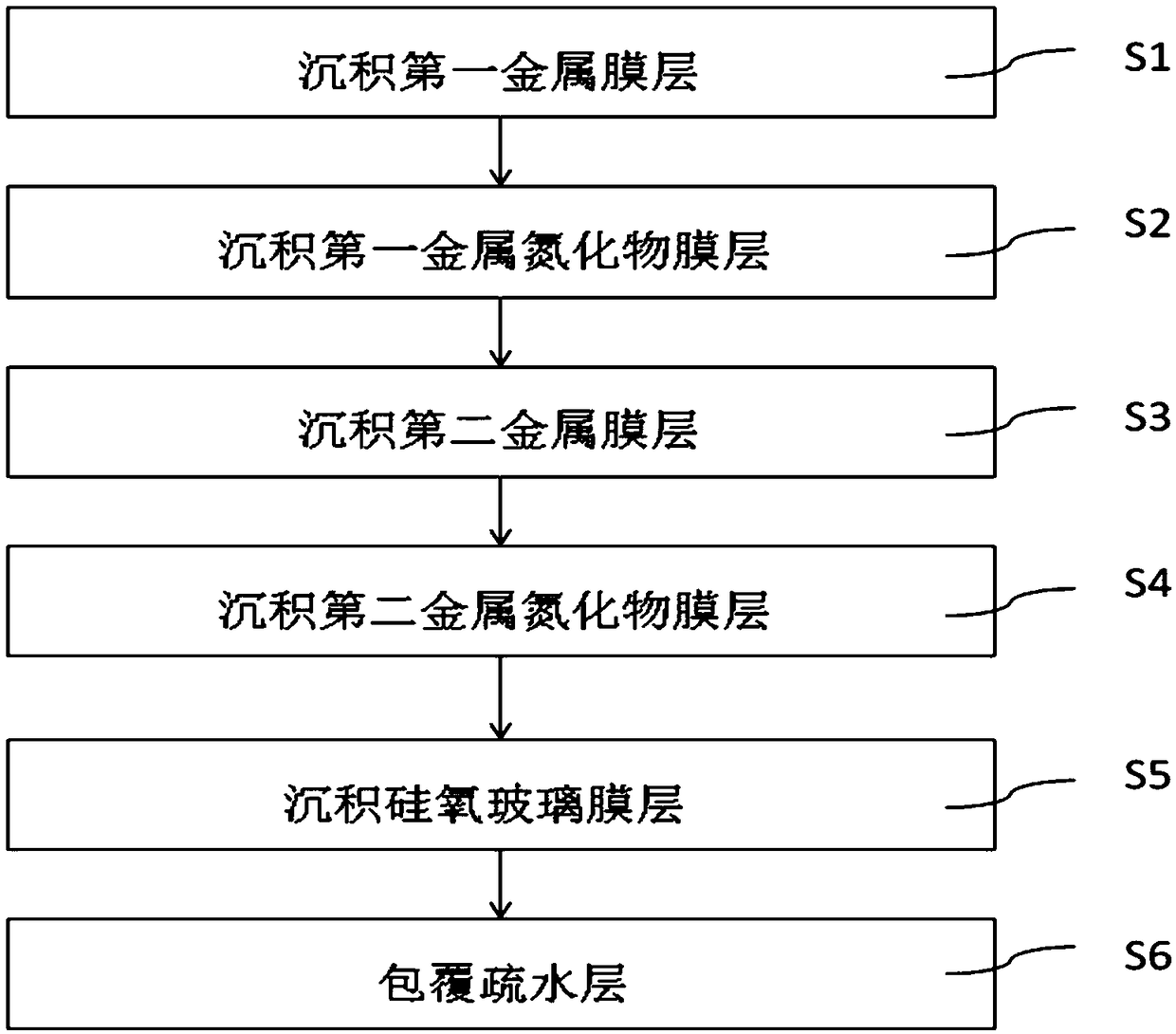

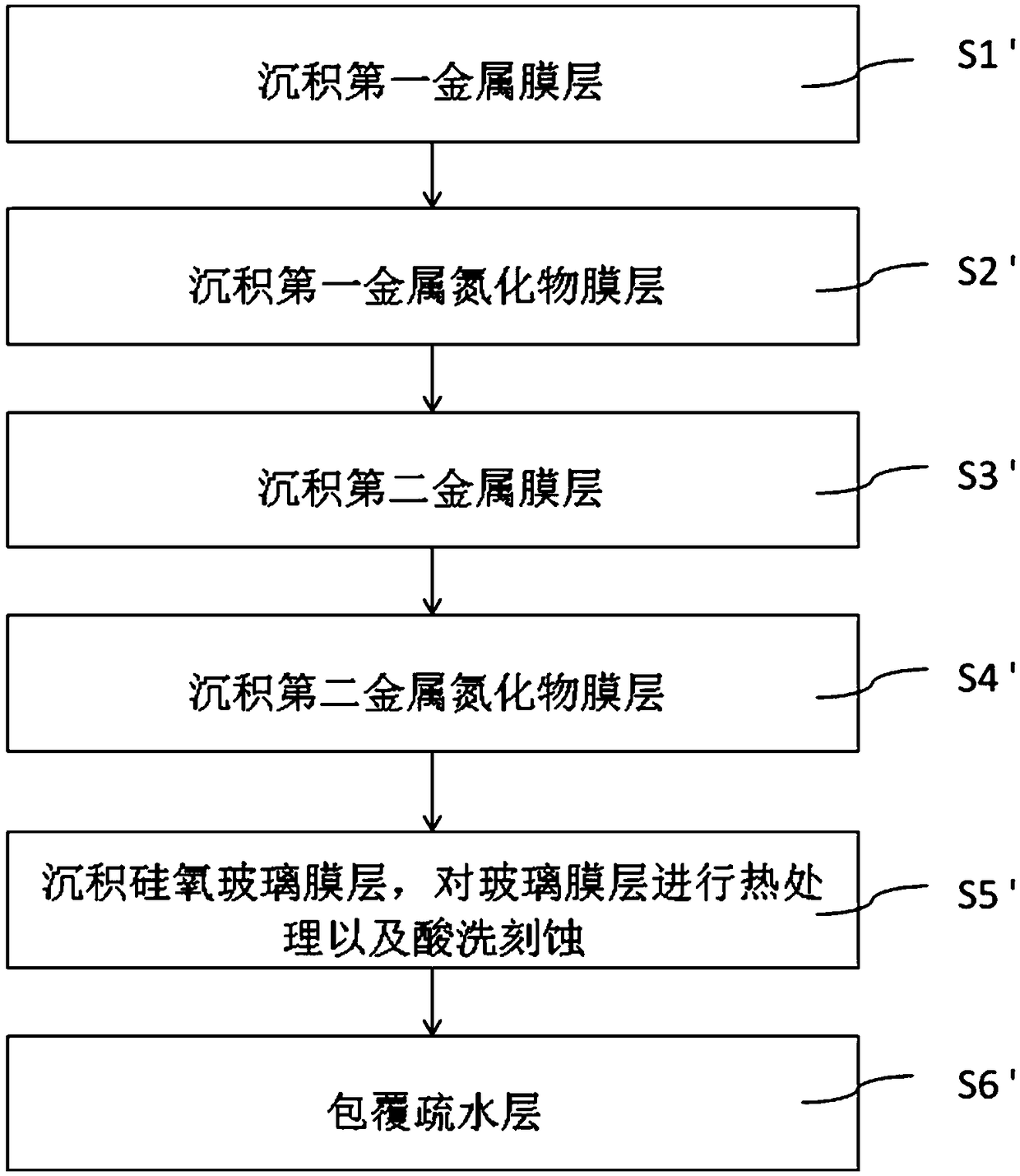

[0070] The present invention also discloses the preparation method of the above-mentioned super-hydrophobic composite coating, the flow chart is as follows figure 2 Shown, this preparation method comprises the steps:

[0071] S1, using a magnetic filter cathode vacuum arc source to deposit a first metal film layer 110 on the surface of the substrate 100;

[0072] S2, using a magnetic filter cathode vacuum arc source to deposit a first metal nitride film layer 120 on the first metal film layer 110 under the condition of feeding nitrogen gas;

[0073] S3, using a magnetic filter cathode vacuum arc source to deposit the second metal film layer 130 on the first metal nitride film layer 120;

[0074] S4, using a magnetic filter cathode vacuum arc source to deposit a second metal nitride film layer 140 on the second metal film layer 130 under the condition of feeding nitrogen gas;

[0075] S5, using vacuum radio frequency magnetron sputtering technology, using borosilicate glass ...

Embodiment 1

[0099] Step 1: Clean the surface of the substrate with a magnetically filtered cathode vacuum Cr arc source. Specifically, the workpiece is placed in a vacuum chamber, and the workpiece is positioned at the exit of the Cr arc source, and the surface of the substrate is bombarded with a high-energy ion beam For cleaning, a pulse negative bias of 800V is applied to the workpiece, the pulse ratio is 70%, and the bombardment time is 5min.

[0100] Step 2, using a magnetic filter cathode vacuum arc source to deposit a Cr film on the surface of the substrate. Specifically, the cathode arc current is controlled at 80A, the deposition negative bias is controlled at 300V, the duty cycle is maintained at 80%, the deposition time is about 1 hour, and the film thickness is controlled at 0.5 μm.

[0101] Step 3, after depositing the Cr film layer, deposit a CrN film layer on the Cr film layer. Specifically, feed 50sccm nitrogen gas to keep the vacuum degree of the vacuum chamber at 1.6×10...

Embodiment 2

[0109] Step 1: Clean the surface of the substrate with a magnetically filtered cathode vacuum Cr arc source. Specifically, the workpiece is placed in a vacuum chamber, and the workpiece is positioned at the exit of the Cr arc source, and the surface of the substrate is bombarded with a high-energy ion beam For cleaning, a pulse negative bias of 800V is applied to the workpiece, the pulse ratio is 70%, and the bombardment time is 5min.

[0110] Step 2, using a magnetic filter cathode vacuum arc source to deposit a Cr film on the surface of the substrate. Specifically, the cathode arc current was controlled at 90A, the deposition negative bias was controlled at 700V, the duty cycle was maintained at 90%, the deposition time was about 0.5 hours, and the film thickness was controlled at 0.8 μm.

[0111] Step 3, after depositing the Cr film layer, deposit a CrN film layer on the Cr film layer. Specifically, 70 sccm nitrogen gas was introduced to keep the vacuum degree of the vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com