Method for magnetic filtration of strip-sectional vacuum cathodic arc plasma

A plasma and cathodic arc technology, applied in ion implantation plating, vacuum evaporation plating, circuit, etc., can solve problems such as small deposition area, unsuitable for large-scale industrial coating application, uneven deposition film, etc., and the method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following provides examples in conjunction with the accompanying drawings and the content of the method of the present invention, so as to further understand the specific implementation manners of the present invention.

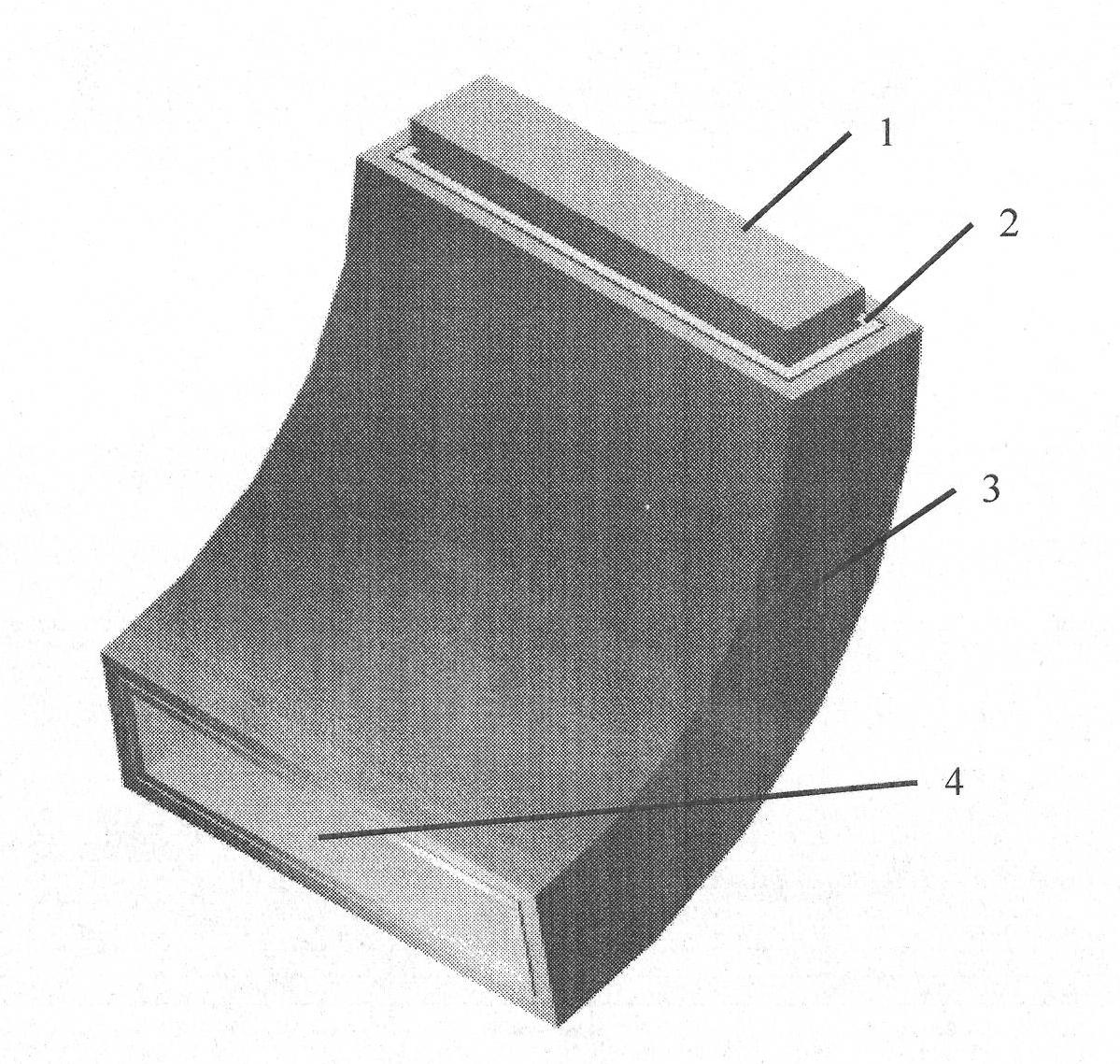

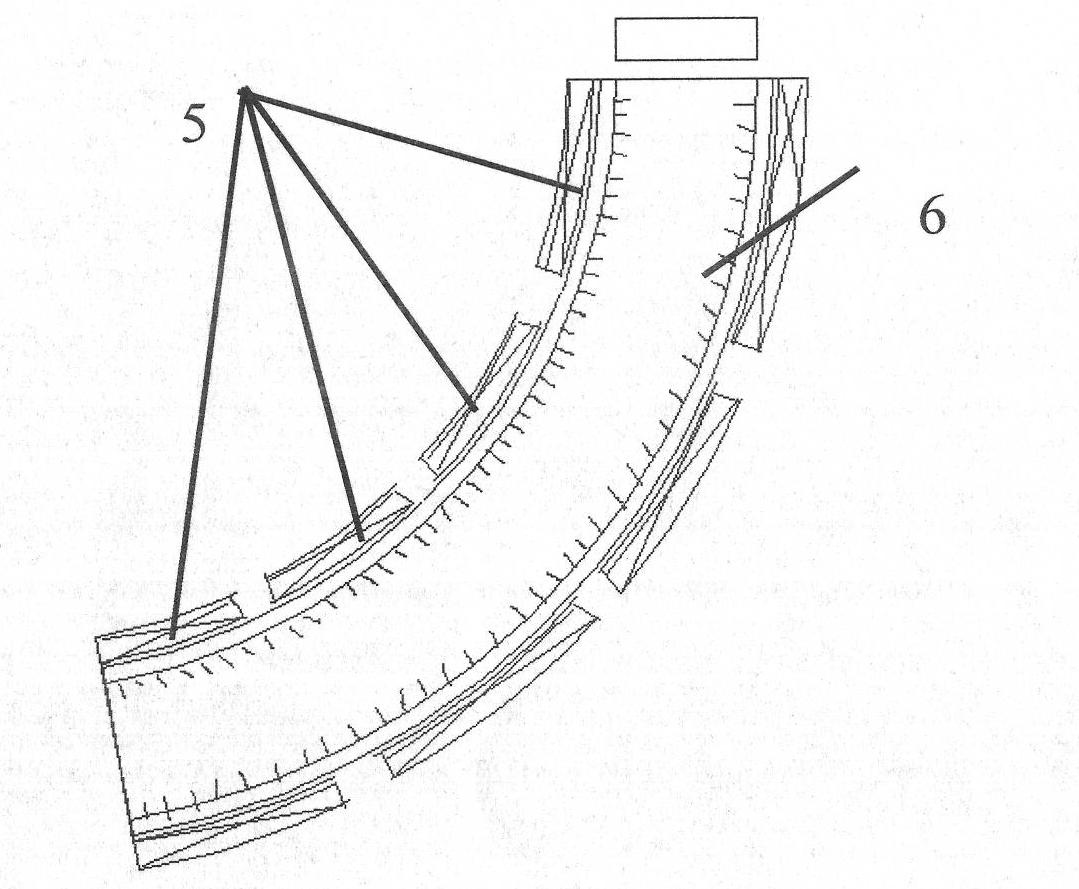

[0024] figure 1 A schematic diagram of the device for magnetically filtering the ribbon plasma generated by the rectangular vacuum cathode arc source using the arc-shaped curved ribbon plasma bending magnetic filter channel is given. After the arc plasma is generated by the vacuum cathode arc target 1 , it enters into the strip-shaped plasma bending magnetic filter channel 2 . Outside the arc-shaped curved ribbon-shaped plasma bending magnetic filter channel, an electromagnetic coil 3 wound with copper wire is wound. The electromagnetic coil 3 surrounds the outside of the ribbon-shaped plasma bending magnetic filter channel 2. Inside the filter channel is formed a magnetic force line (not shown) that is substantially parallel to the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com