Patents

Literature

34results about How to "High material yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

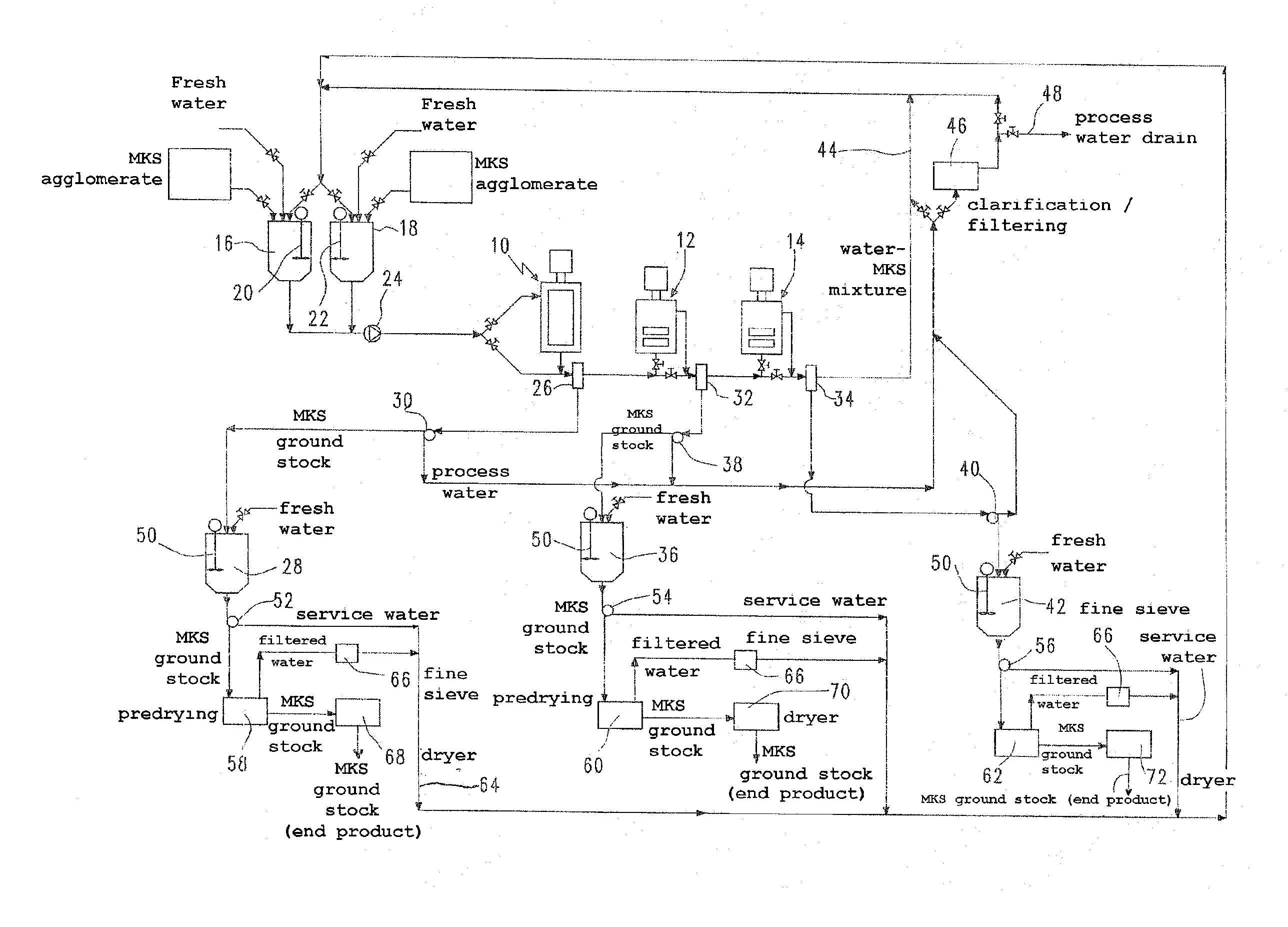

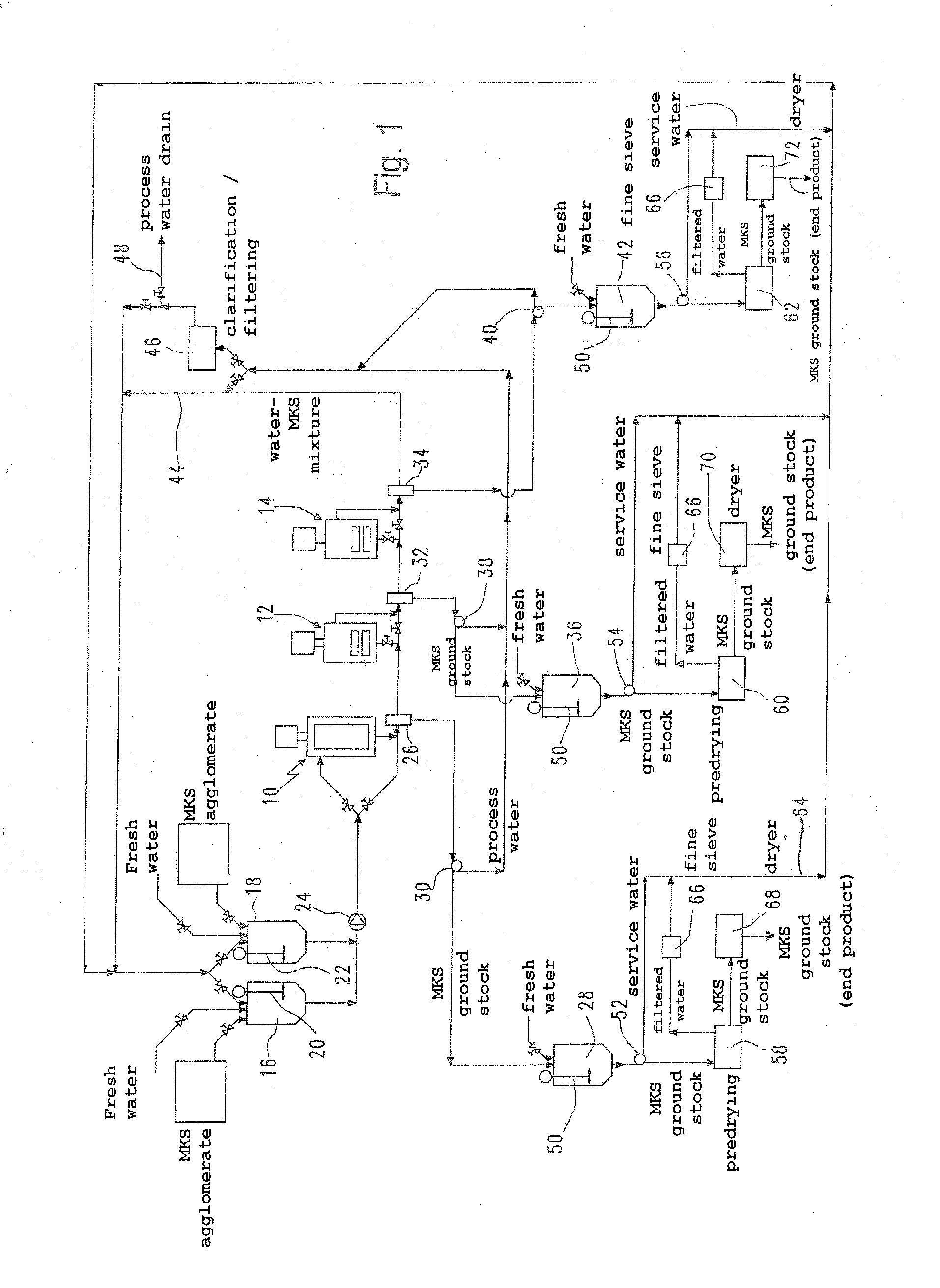

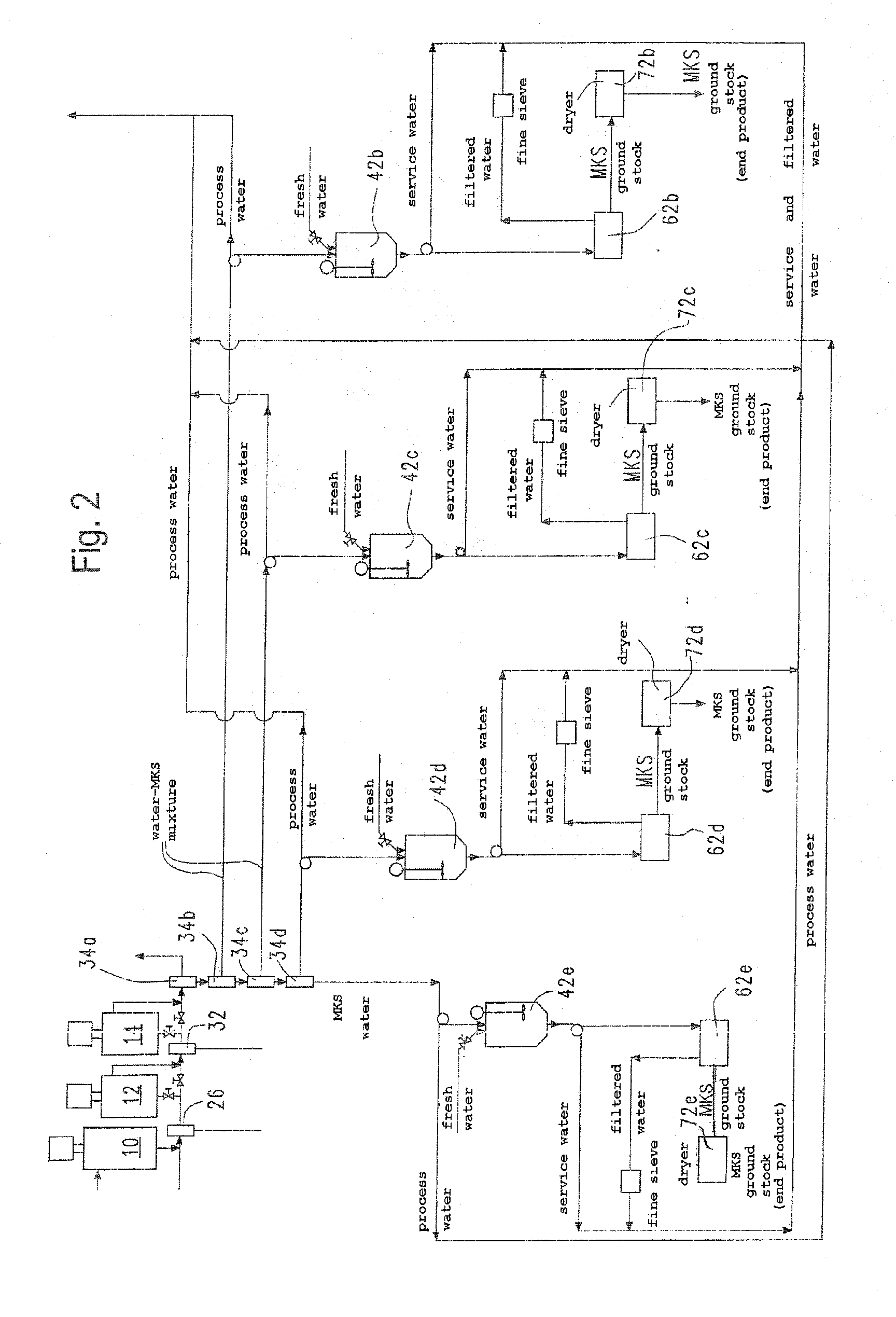

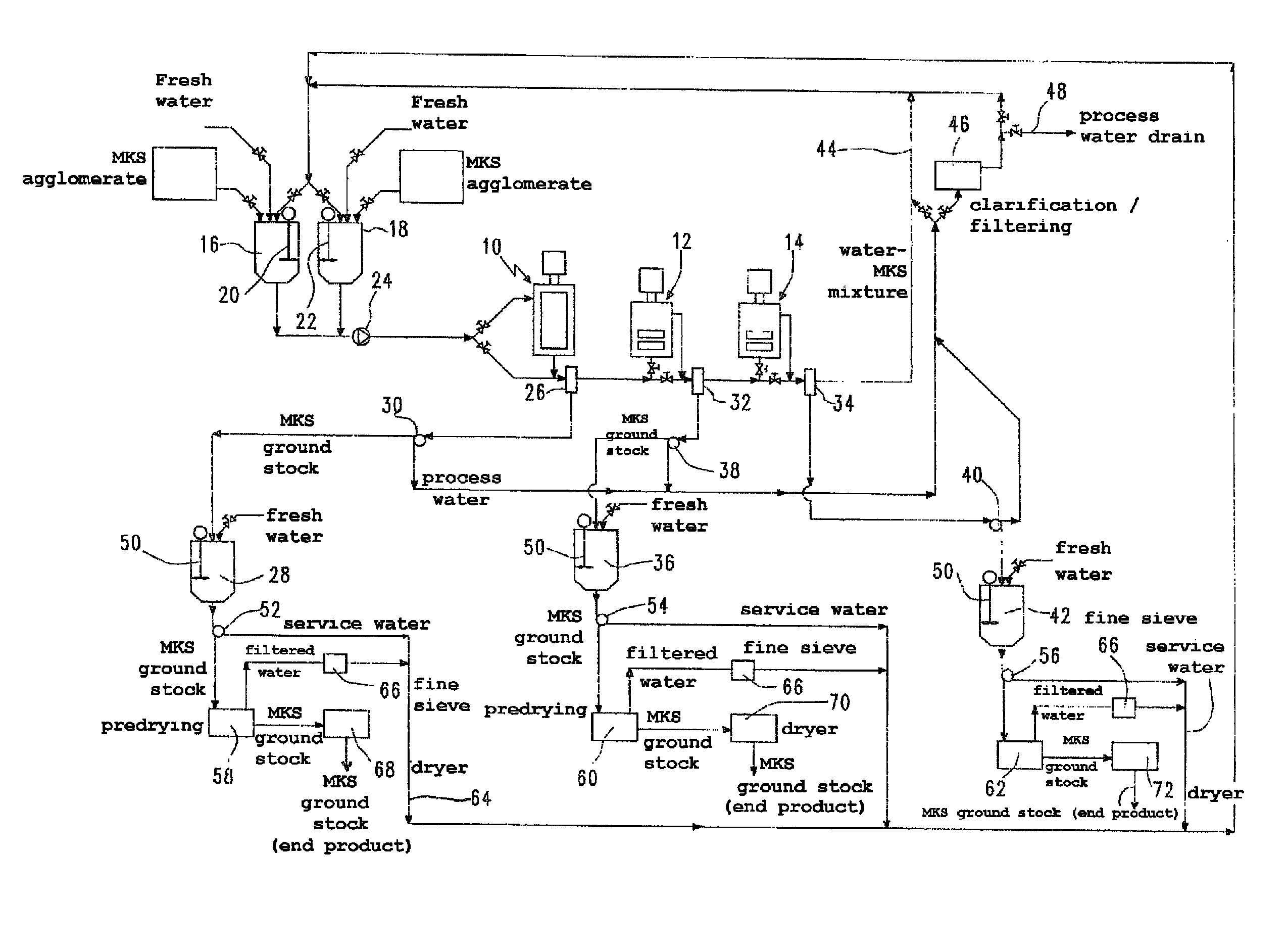

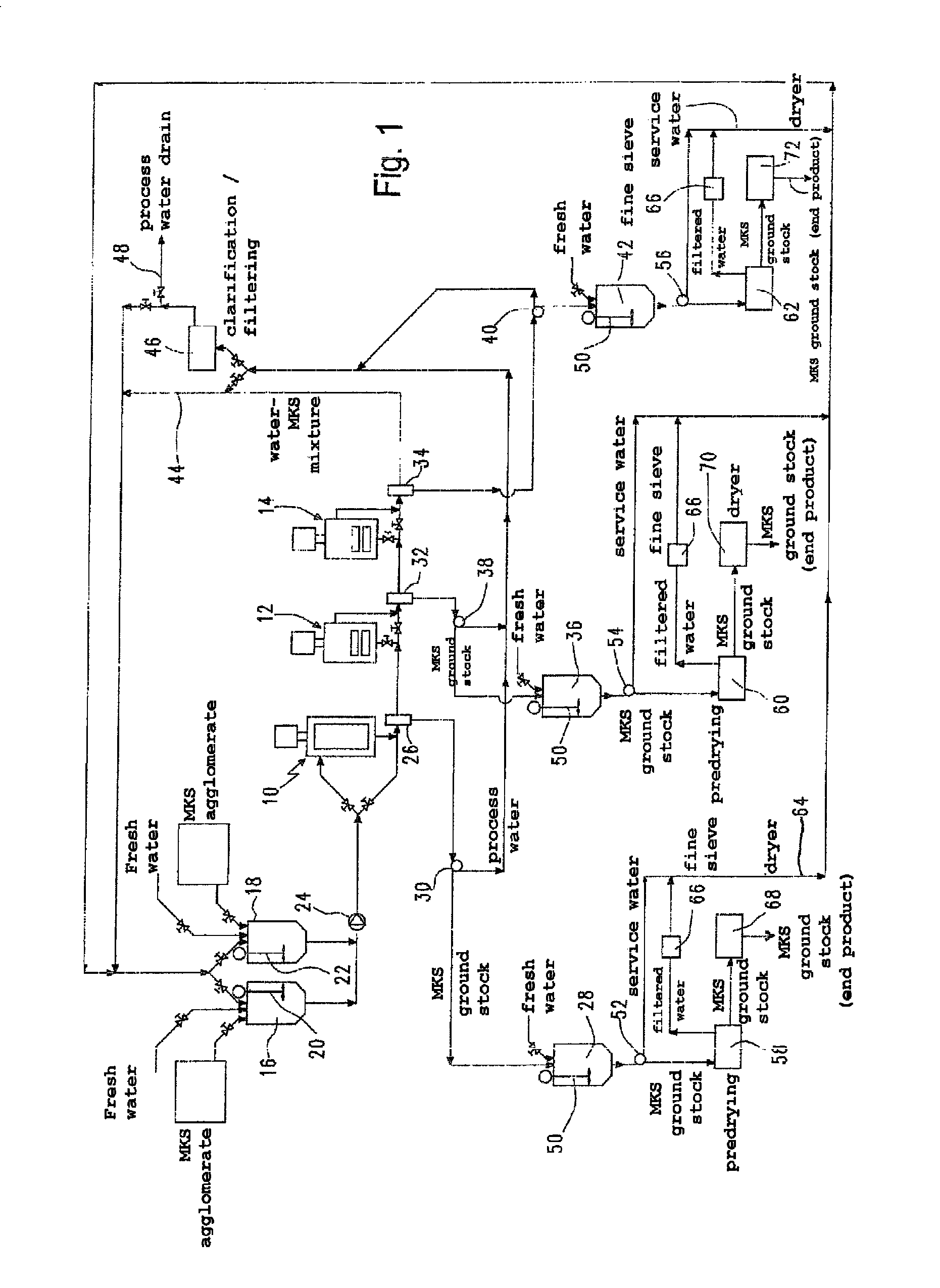

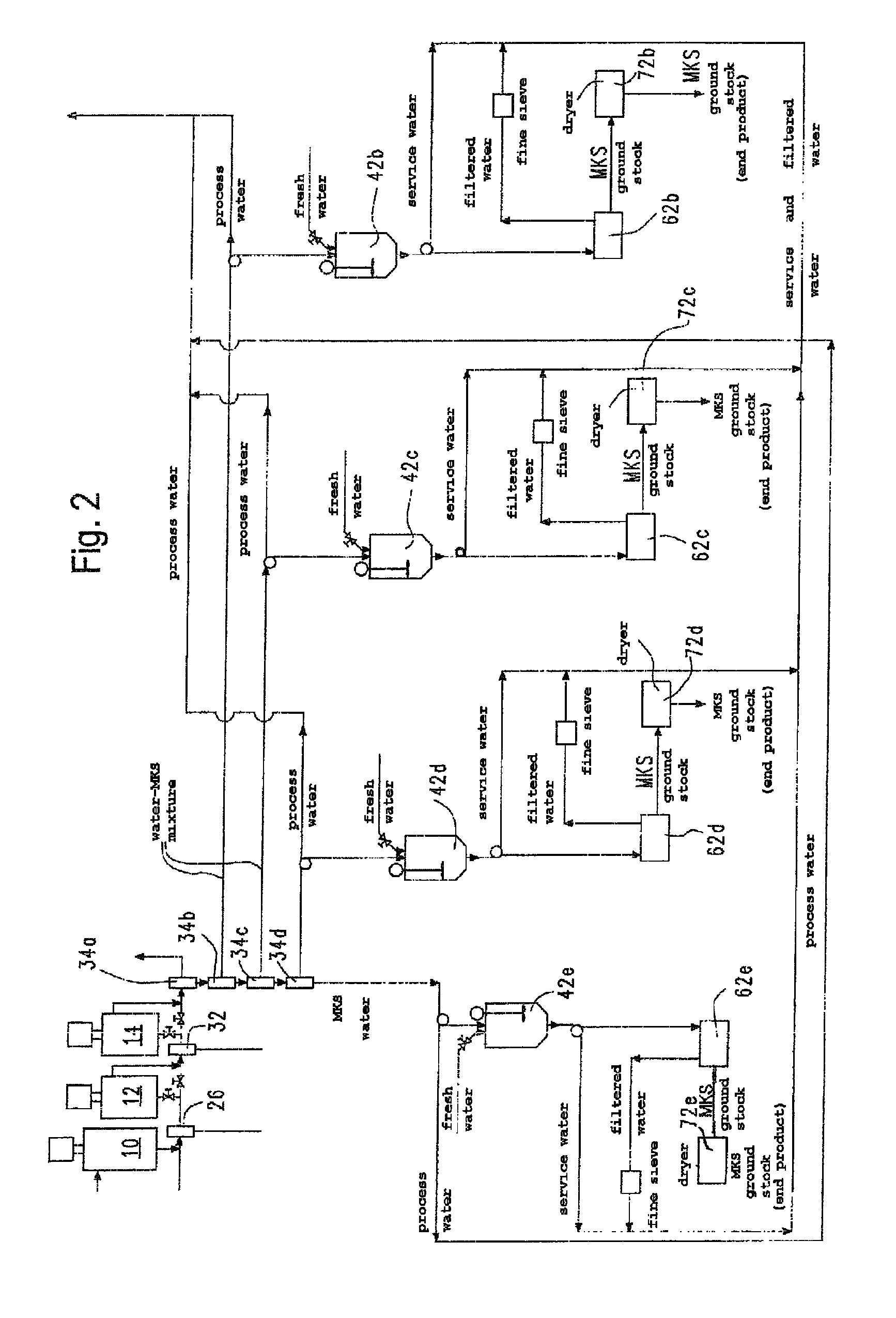

Method and Apparatus for Comminuting and Cleaning of Waste Plastic

InactiveUS20080191069A1Improve consistencyHigh material yieldSolid waste disposalWood working apparatusThick wallFine grain

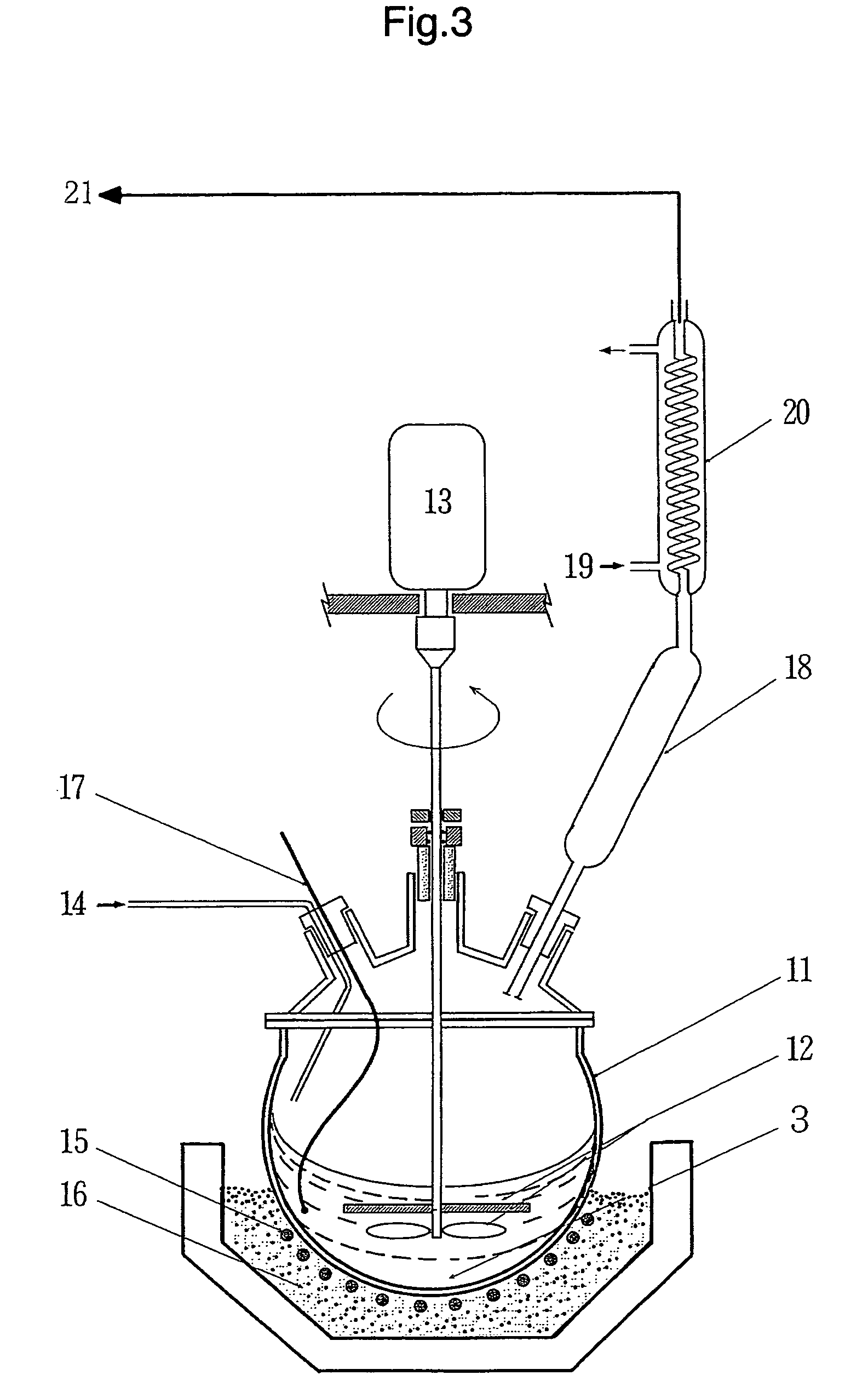

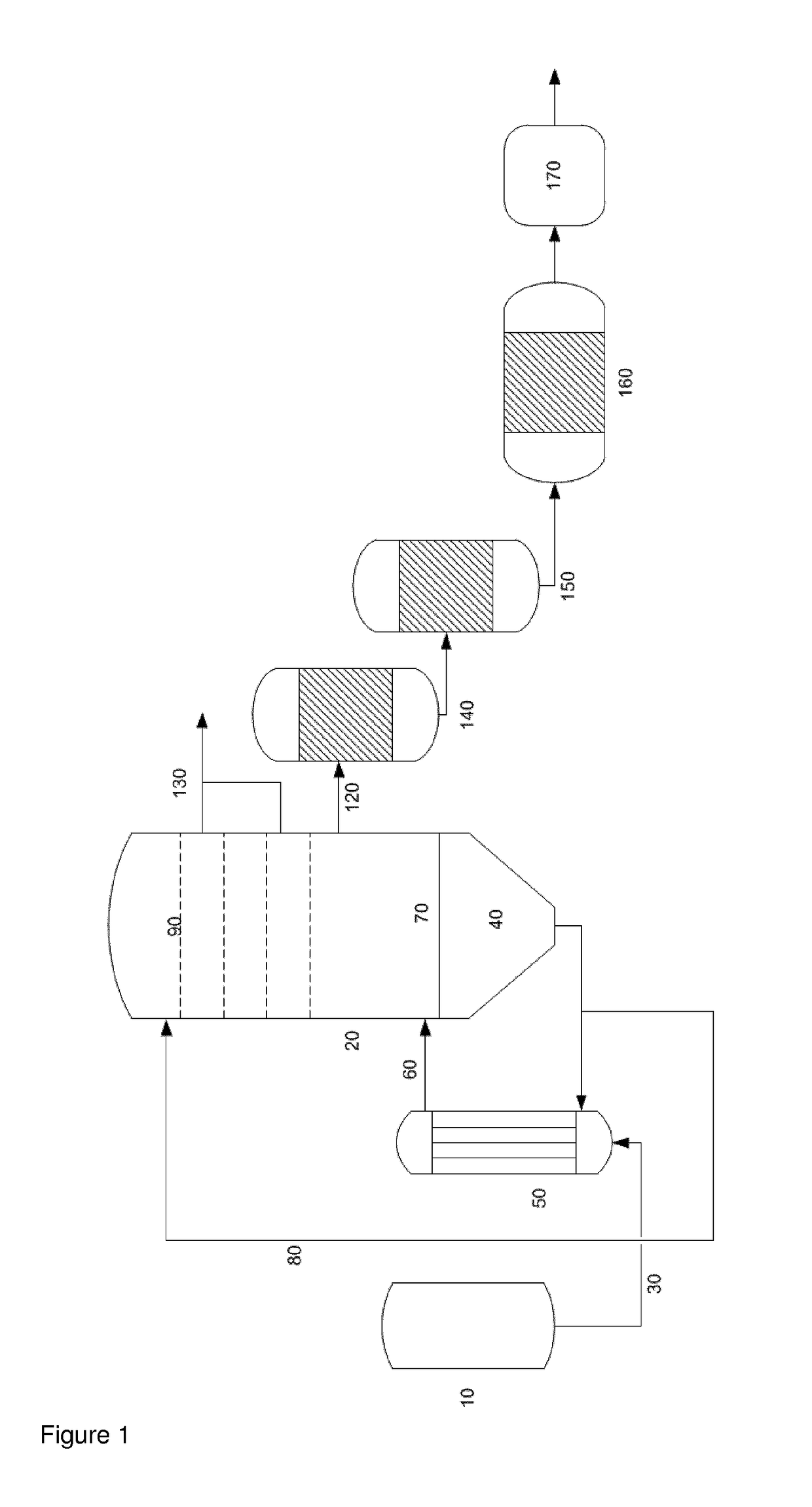

Method for comminuting and cleaning waste plastic, in particular, mixed plastic (MKS) with the following steps: a compacted material, especially, an agglomerate is produced from film scraps or film remnants comminuted into flakes and / or thick-walled plastic parts chopped up into chips, the compacted material is introduced into a disc or drum refiner and is ground therein in the presence of water, wherein the portion of compacted material of the goods located in the refiner amounts to at least 10 percent by weight, a fine grain fraction is removed from the ground stock exiting from the refiner, the remaining ground stock is washed and either mechanically dewatered and dried, or pulverized again in a further refiner stage in the presence of water, and subsequently dewatered and dried.

Owner:CVP CLEAN VALUE PLASTICS GMBH

Method and apparatus for comminuting and cleaning of waste plastic

InactiveUS7757974B2Improve consistencyHigh material yieldSolid waste disposalPlastic recyclingThick wallEngineering

Method for comminuting and cleaning waste plastic, in particular, mixed plastic (MKS) with the following steps: a compacted material, especially, an agglomerate is produced from film scraps or film remnants comminuted into flakes and / or thick-walled plastic parts chopped up into chips, the compacted material is introduced into a disc or drum refiner and is ground therein in the presence of water, wherein the portion of compacted material of the goods located in the refiner amounts to at least 10 percent by weight, a fine grain fraction is removed from the ground stock exiting from the refiner, the remaining ground stock is washed and either mechanically dewatered and dried, or pulverized again in a further refiner stage in the presence of water, and subsequently dewatered and dried.

Owner:CVP CLEAN VALUE PLASTICS GMBH

Tube target

InactiveUS6793784B1Uniform and fine-grained structureSimple and low-costCellsElectric discharge tubesMaterials scienceFine grain

A tube target for cathode sputtering installations, and a process for producing a cylindrical hollow body for such a tube target and its use. The problem of providing a simple and low-cost process for producing a cylindrical hollow body for a tube target and of providing a cylindrical hollow body with a uniform, fine-grained structure is solved by the cylindrical hollow body being produced by centrifugal casting of a melt.

Owner:HERAEUS MATERIALS TECHNOLOGY GMBH & CO KG

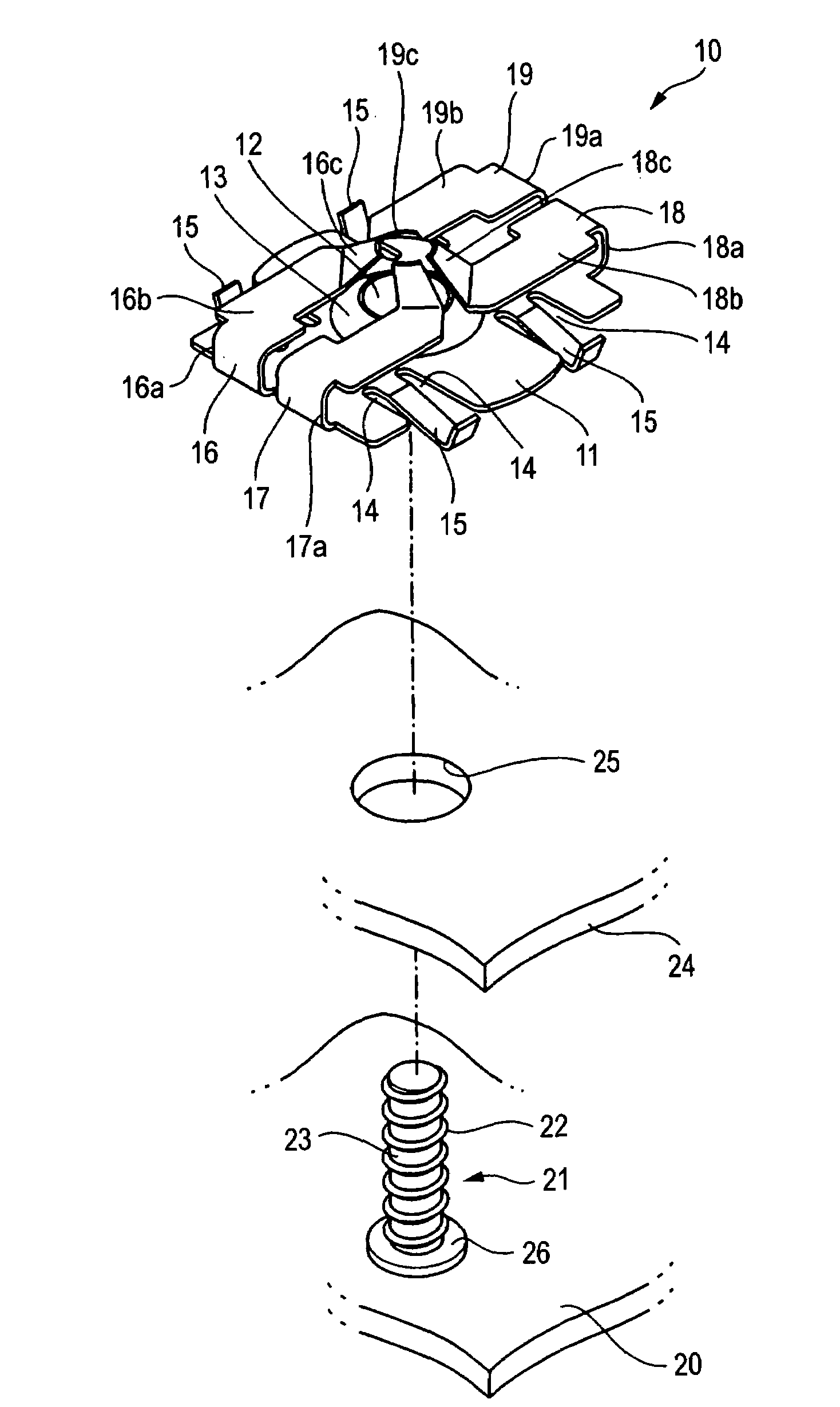

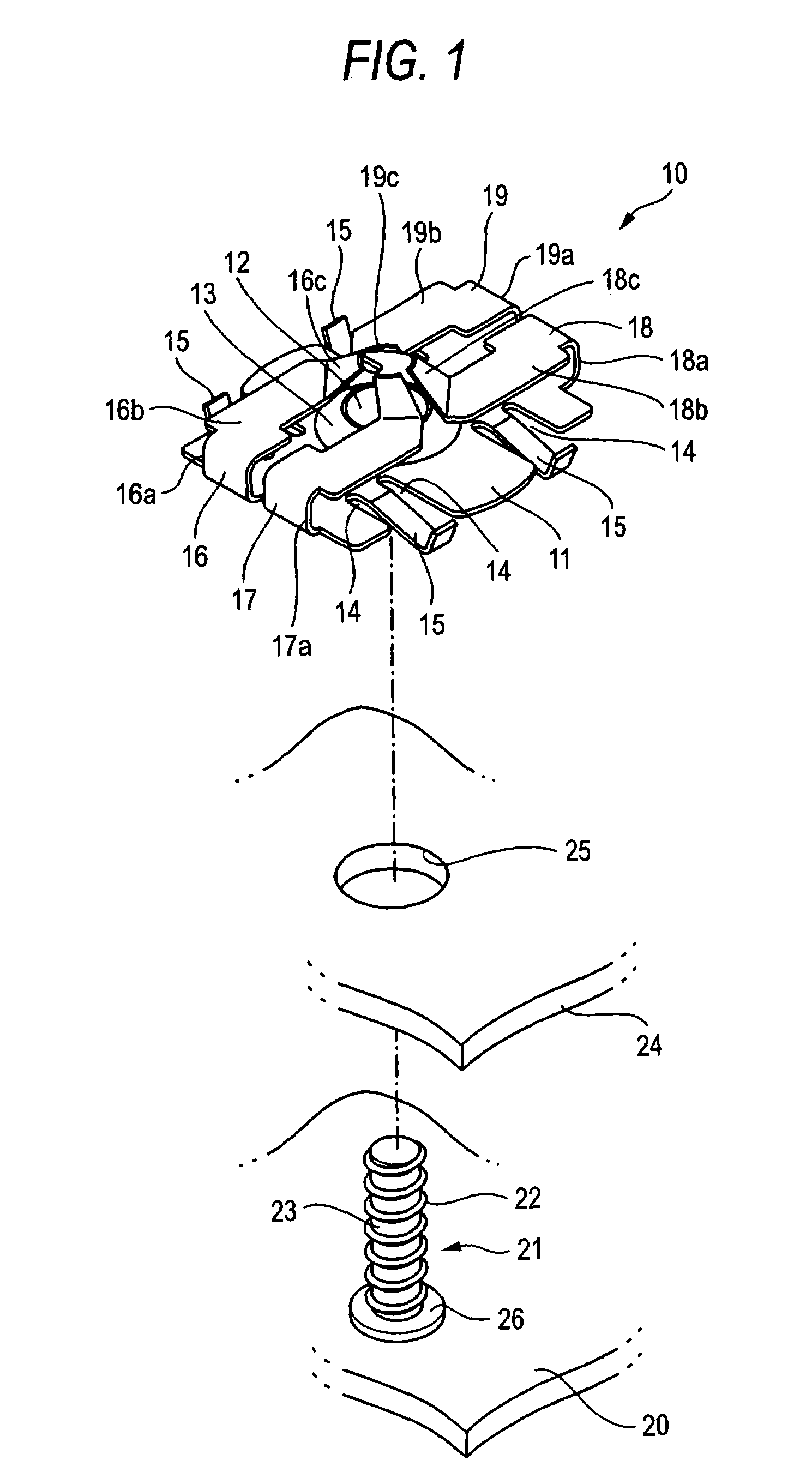

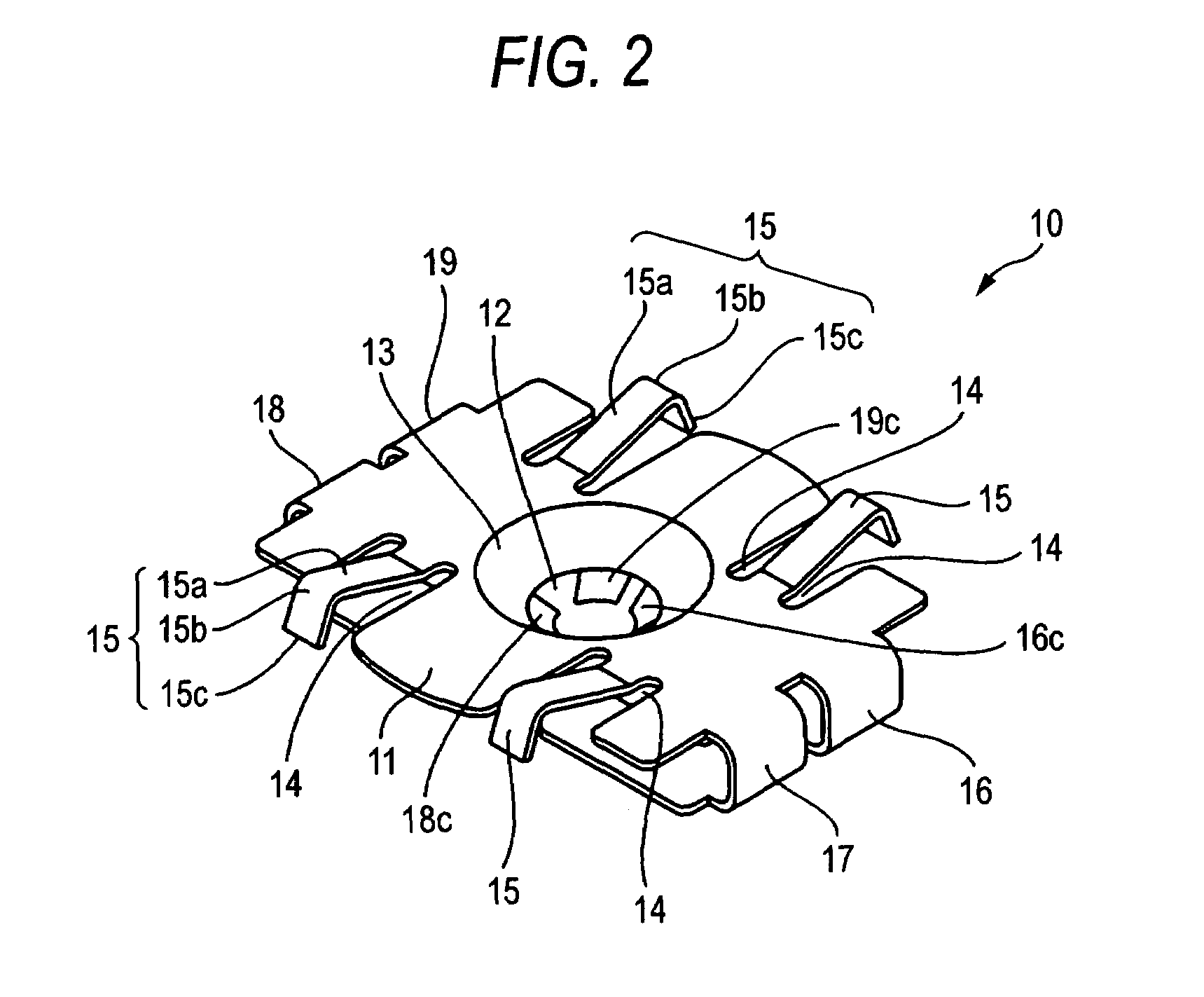

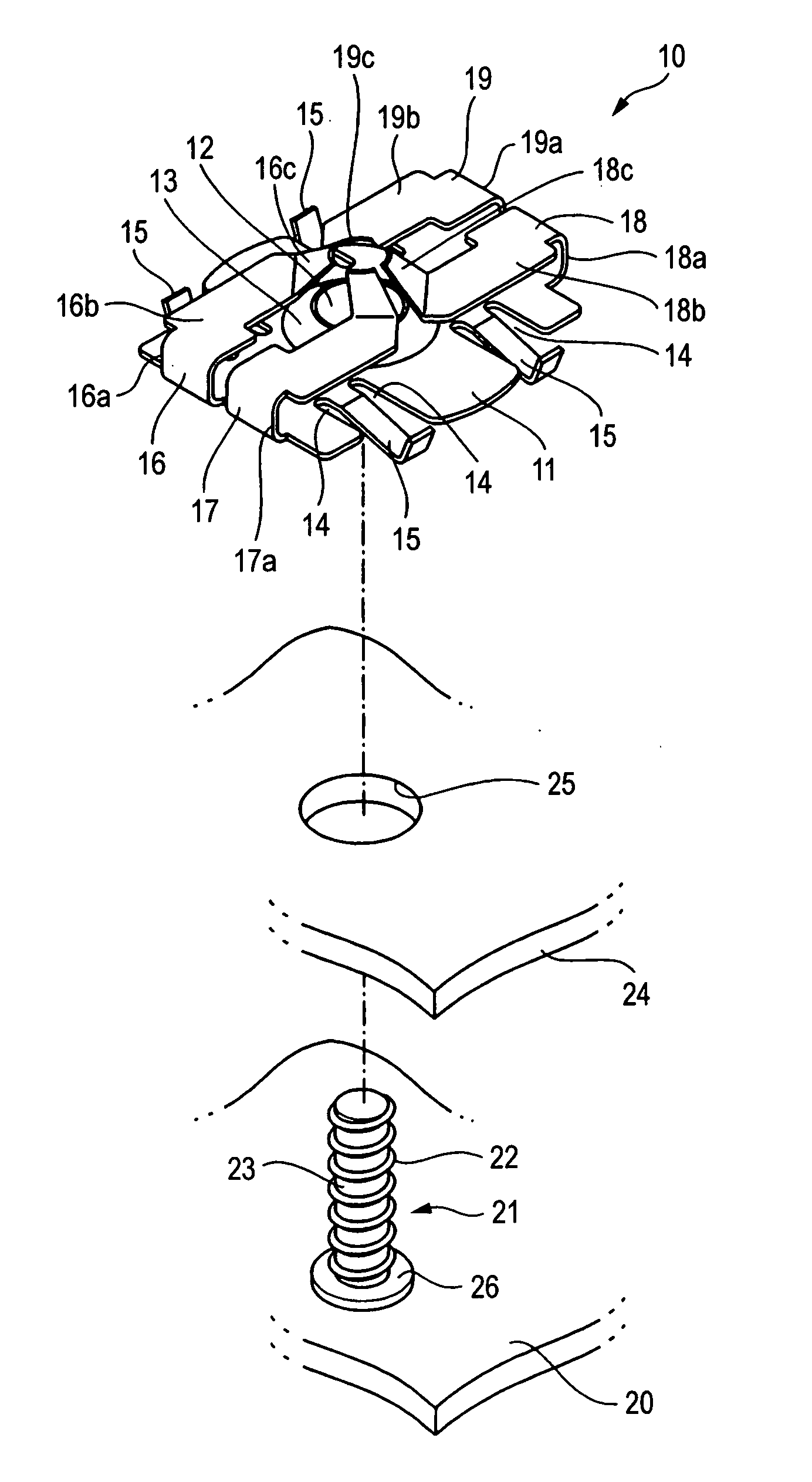

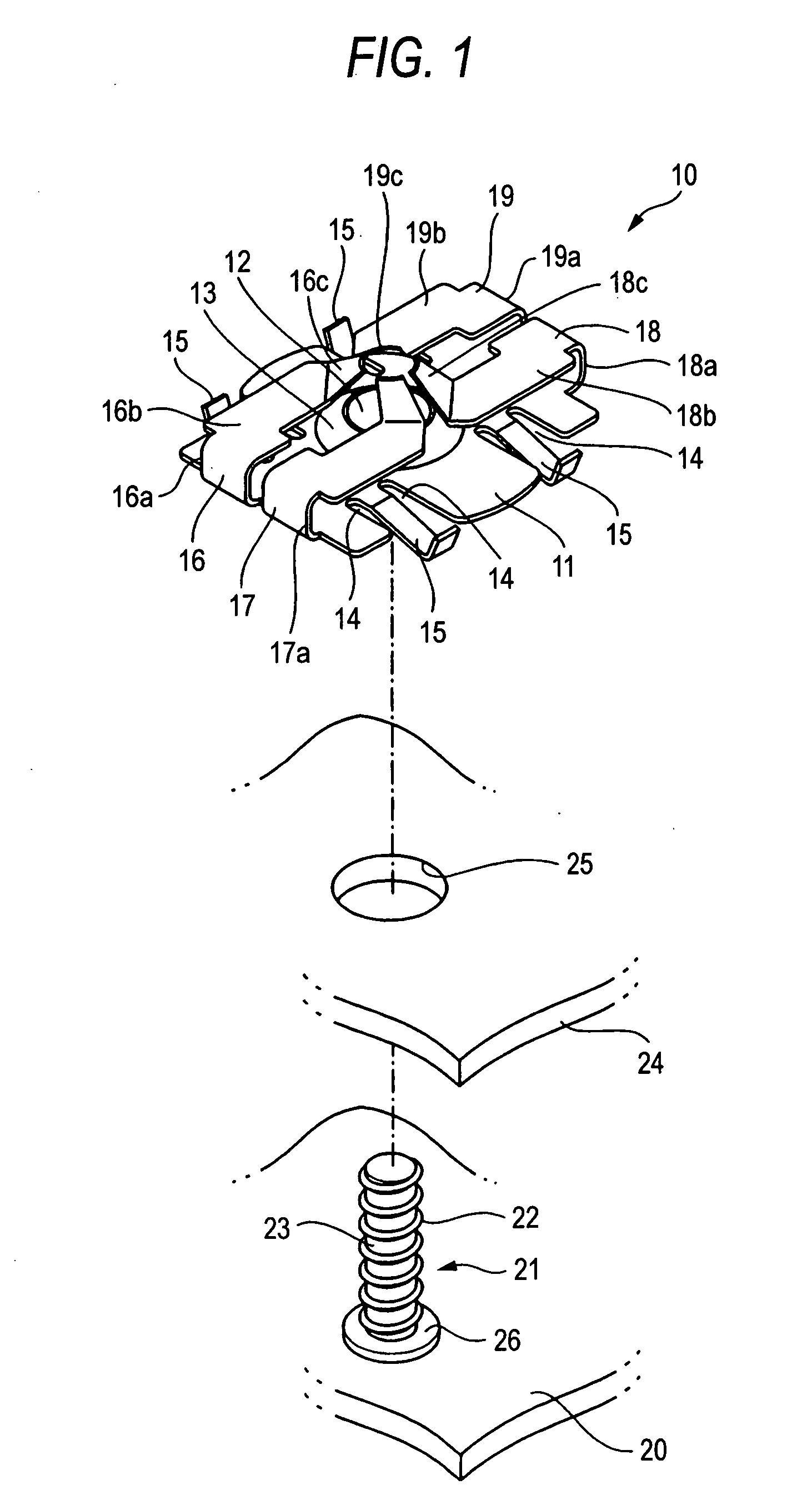

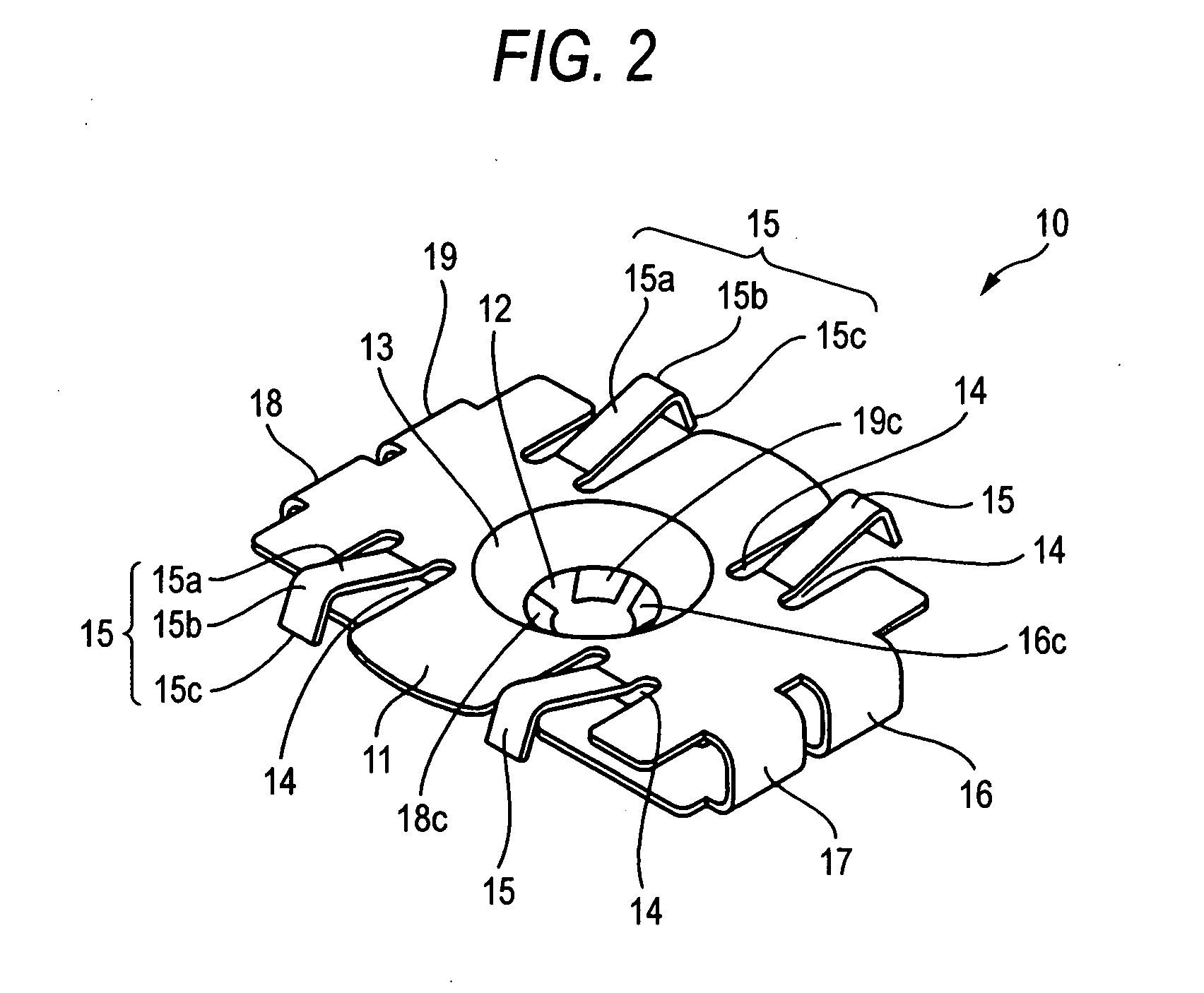

Push nut

A push nut including a base plate formed with a bolt passing hole at a center of the base plate and four engaging pieces. Pairs of engaging pieces extend respectively from a pair of opposing sides of the base plate, base portions of the four engaging pieces are folded back to have a U-shape, and tip end portions of the engaging pieces extend to a surrounding of the bolt passing hole. The tip end portions of the four engaging pieces surround a periphery of the bolt passing hole. The four engaging pieces incline toward an insertion direction of a bolt and elastically abut against an outer circumference of the bolt, which is inserted into the bolt passing hole.

Owner:PIOLAX CO LTD

Fabrication of a scintillator material of elpasolite type

ActiveUS9599727B2High material yieldImprove yieldPolycrystalline material growthElectrical apparatusRare-earth elementMetallurgy

A process for fabricating a crystalline scintillator material with an elpasolite structure that has a theoretical composition of A2BC(1-y)MyX(6-y) can include conducting crystallization by cooling from a melt bath including r moles of A and s moles of B. A is chosen from Cs, Rb, K, and Na. B is chosen from Li, K, and Na. C is chosen from athe rare earth elements, Al, and Ga. M is chosen from the alkaline earth elements. X is chosen from F, Cl, Br, and I, and y represents the atomic fraction of substitution of C by M and is in the range extending from 0 to 0.05. The melt bath can be in contact with the material containing A and B in such a way that 2s / r is above 1. The process shows an improved fabrication yield. The crystals formed therefrom can have improved scintillation properties.

Owner:LUXIUM SOLUTIONS LLC

Push nut

A push nut including a base plate formed with a bolt passing hole at a center of the base plate and four engaging pieces. Pairs of engaging pieces extend respectively from a pair of opposing sides of the base plate, base portions of the four engaging pieces are folded back to have a U-shape, and tip end portions of the engaging pieces extend to a surrounding of the bolt passing hole. The tip end portions of the four engaging pieces surround a periphery of the bolt passing hole. The four engaging pieces incline toward an insertion direction of a bolt and elastically abut against an outer circumference of the bolt, which is inserted into the bolt passing hole.

Owner:PIOLAX CO LTD

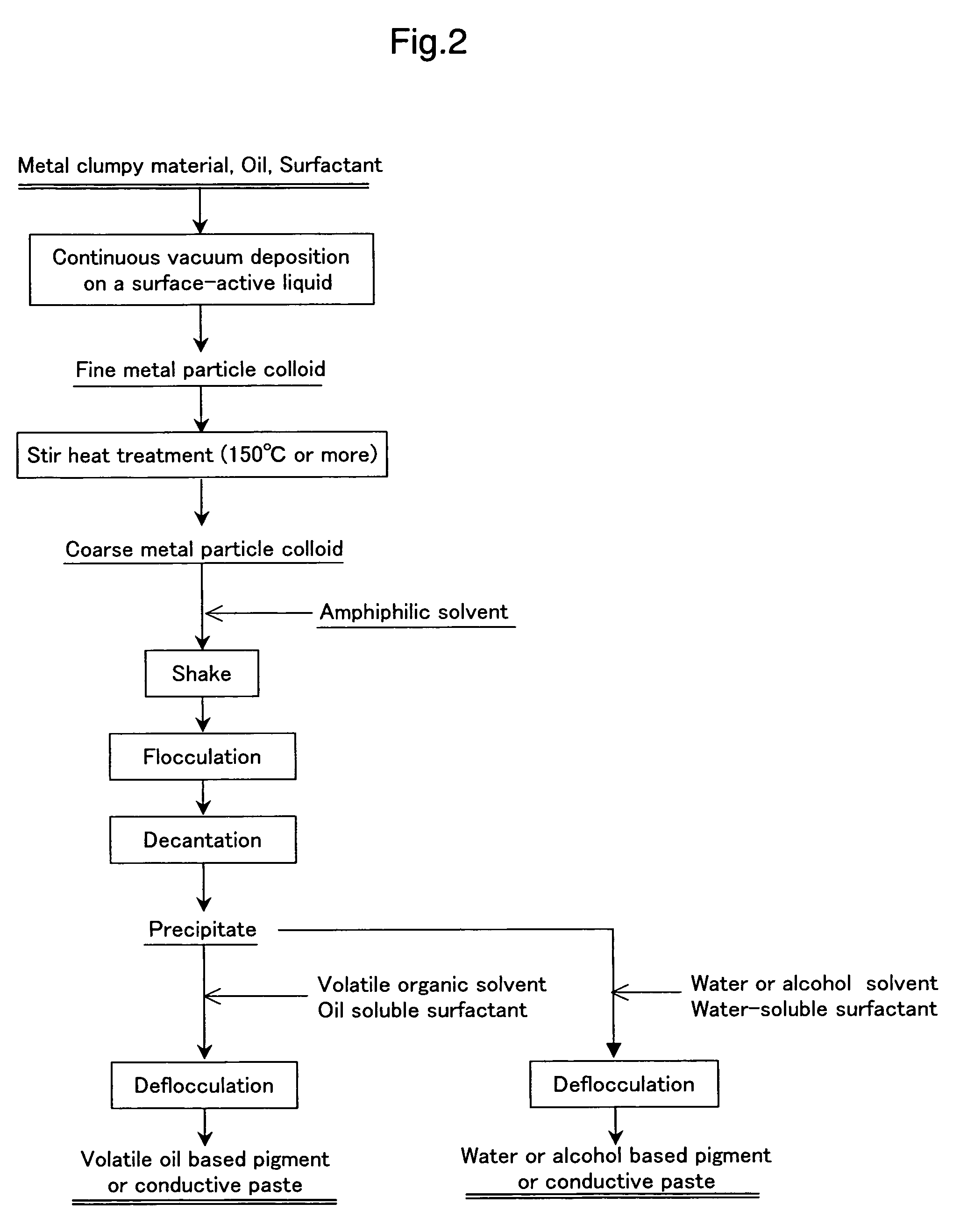

Fine metal particle colloidal solution, conductive paste material, conductive ink material, and process for producing the same

ActiveUS7780876B2Material yield and inexpensively and efficientlyControl fluctuationsMaterial nanotechnologyNanostructure manufactureHigh concentrationConductive paste

A colloidal solution of fine particles of metal or alloy having an average grain size of 10 nm or more is provided which is heat treated to cause coloration, or a metal colloidal pigment having inherent color, a conductive paste material or a conductive ink for printed substrate electronic parts or the like based on a colloid prepared by dispersing fine metal particles at high concentration in a liquid is provided.

Owner:NAT INST FOR MATERIALS SCI

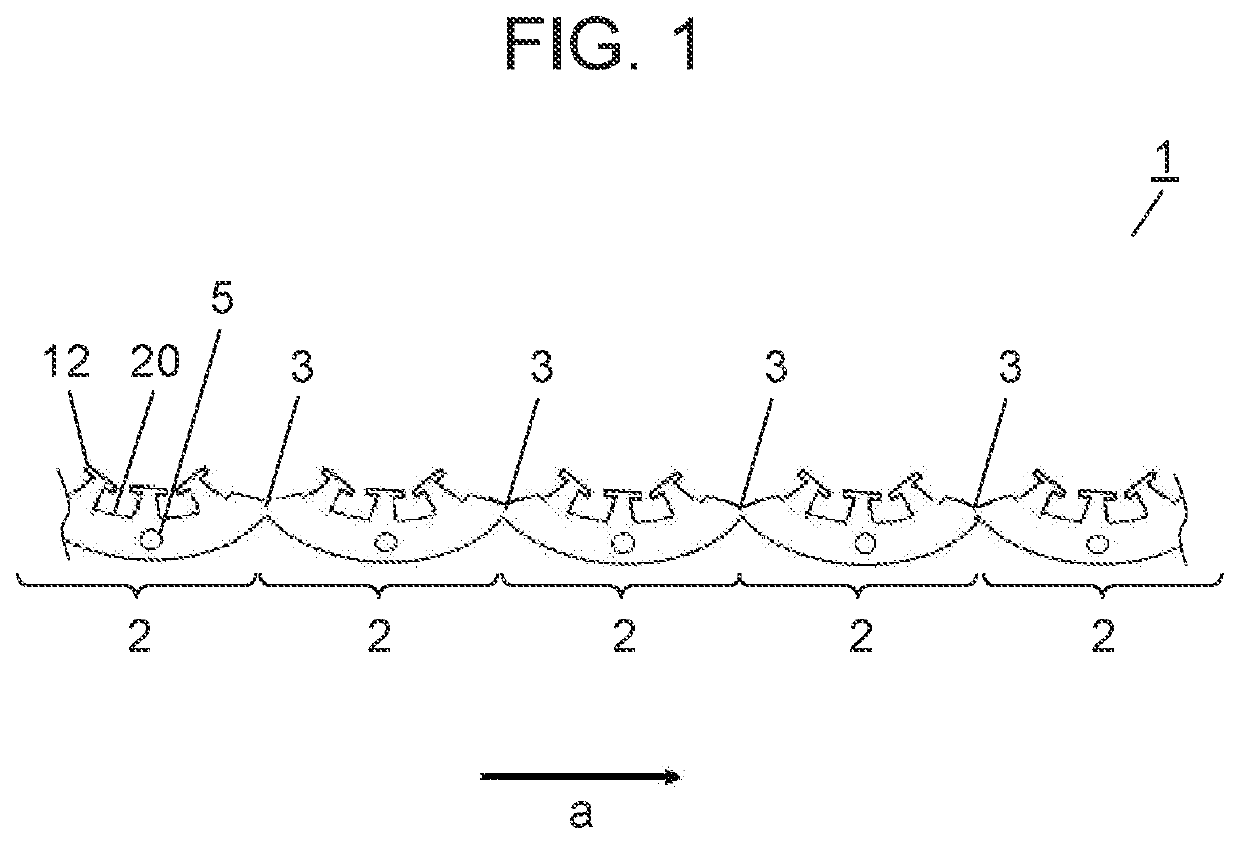

Honeycomb structure and method for manufacturing the same

InactiveUS20090252919A1Improve thermal shock resistanceAvoid damageDispersed particle filtrationHollow filament manufactureHoneycomb structureBiomedical engineering

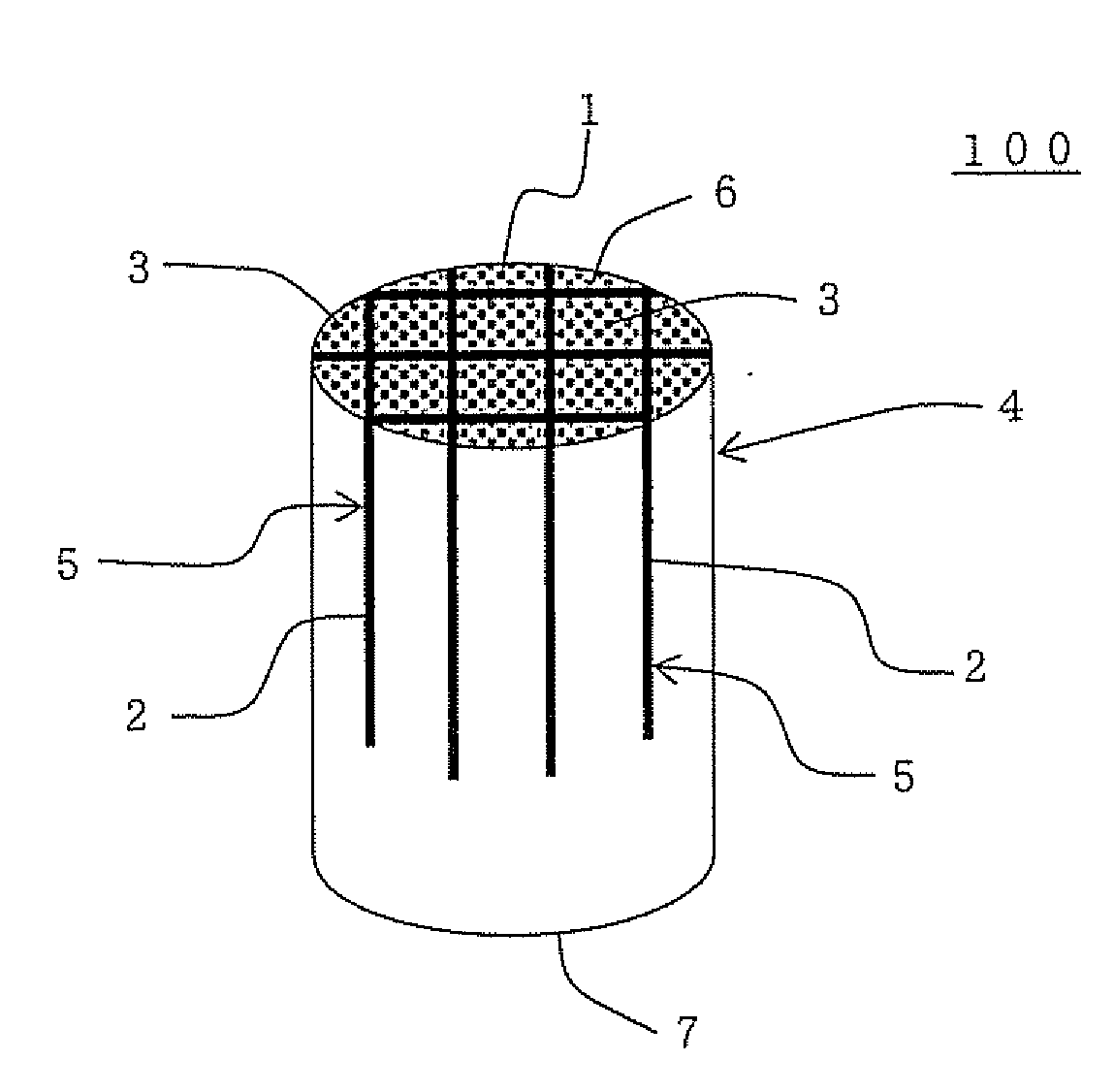

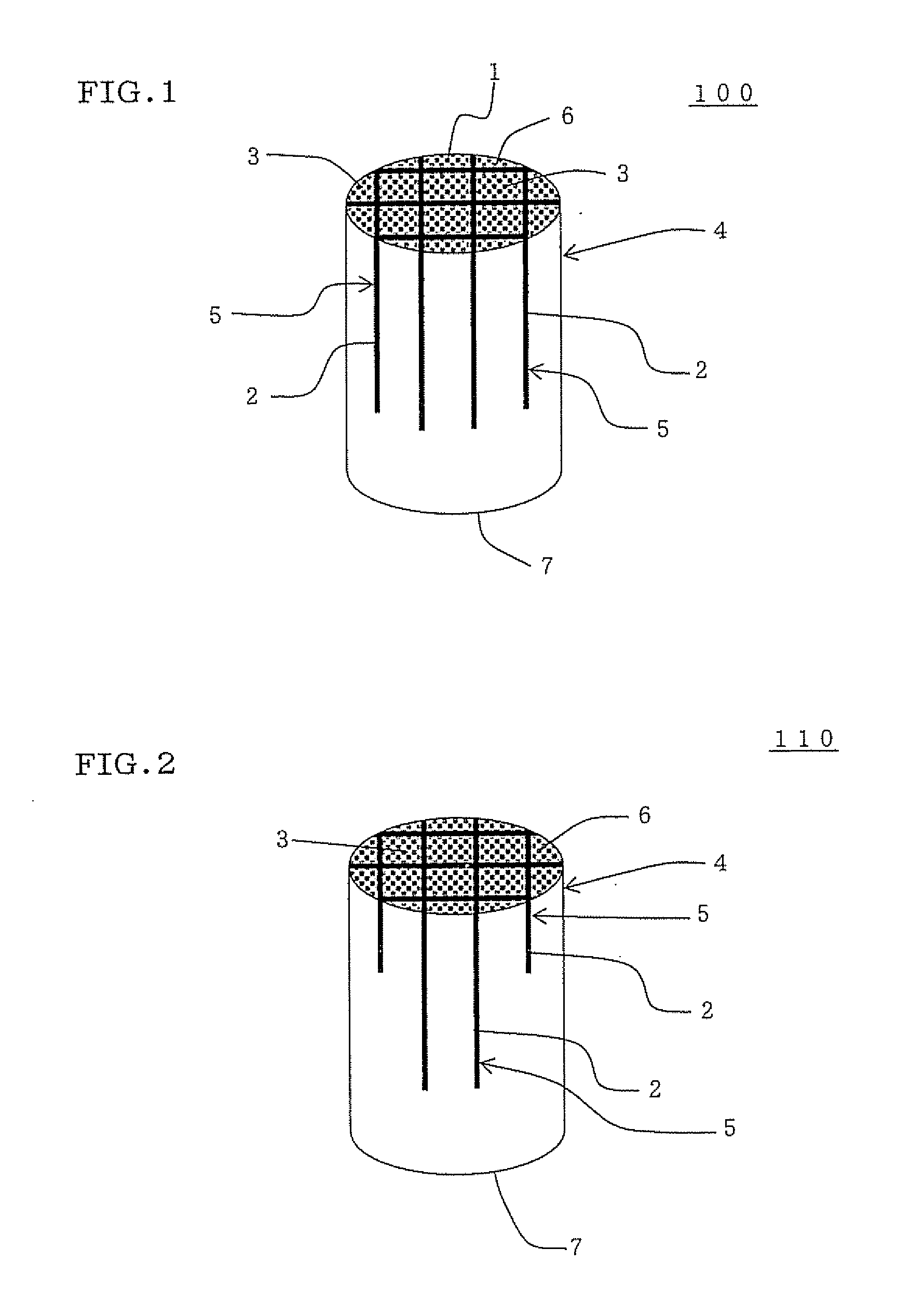

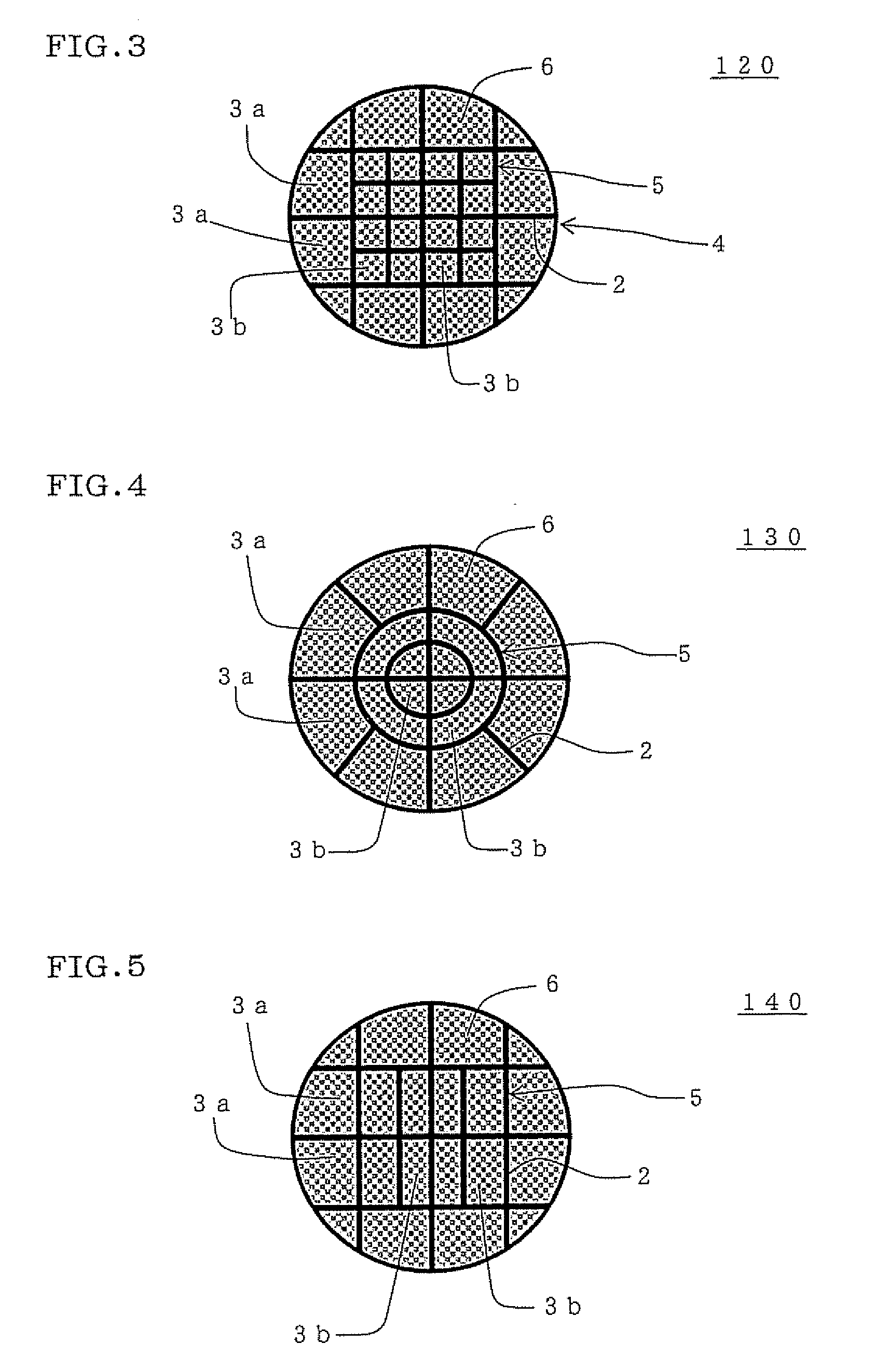

A honeycomb structure 100 includes: a honeycomb structured portion 4 having partition walls separating and forming a plurality of cells 1 functioning as fluid passages and extending through from one end face 6 to the other end face 7 and having a plurality of partial segments 3 separated and formed by a plurality of slits 2 extending in a cell extension direction and not reaching at least one of the end faces, and a buffer portions 5 formed by filling a filler in the whole slits 2. The honeycomb structured portion 4 preferably has a plurality of partial segments 3 separated and formed by the plurality of slits 2 extending from the one end face in a cell extension direction and not reaching the other end face 7. The honeycomb structure has excellent thermal shock resistance.

Owner:NGK INSULATORS LTD

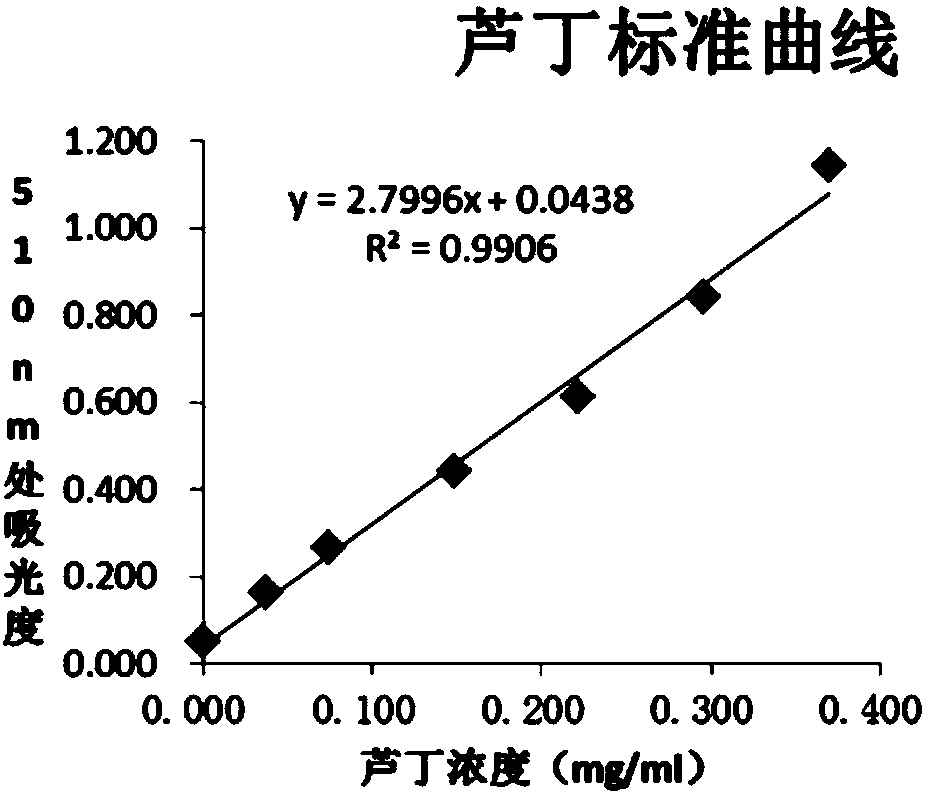

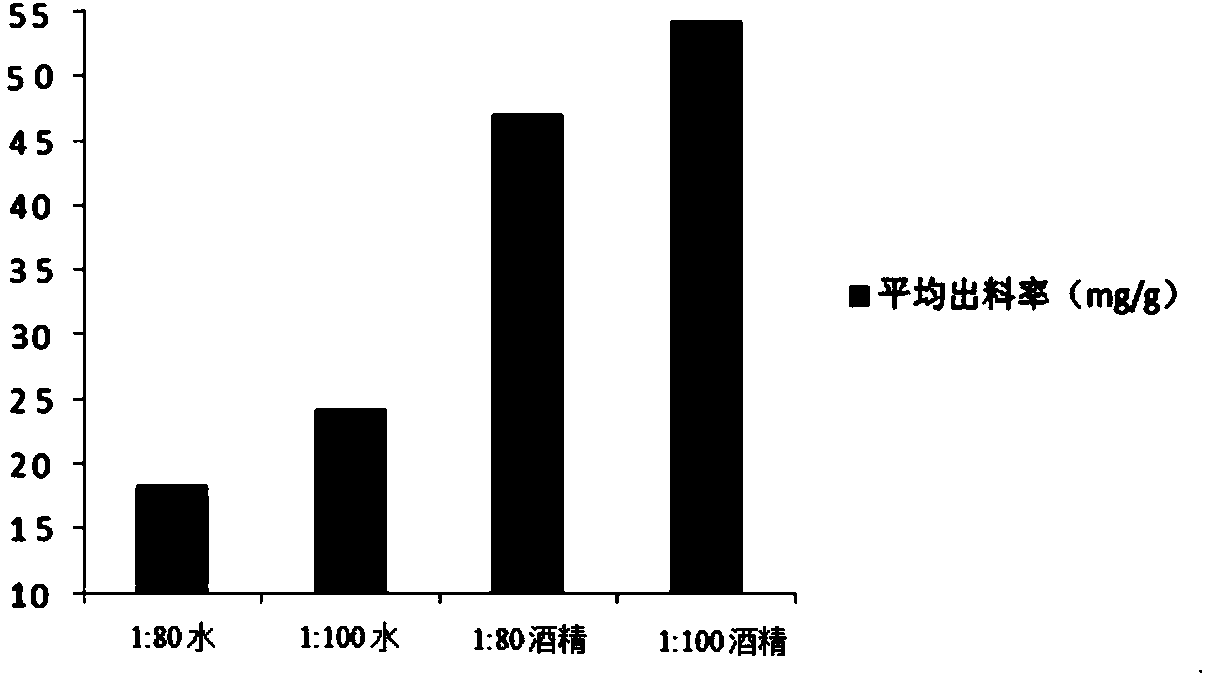

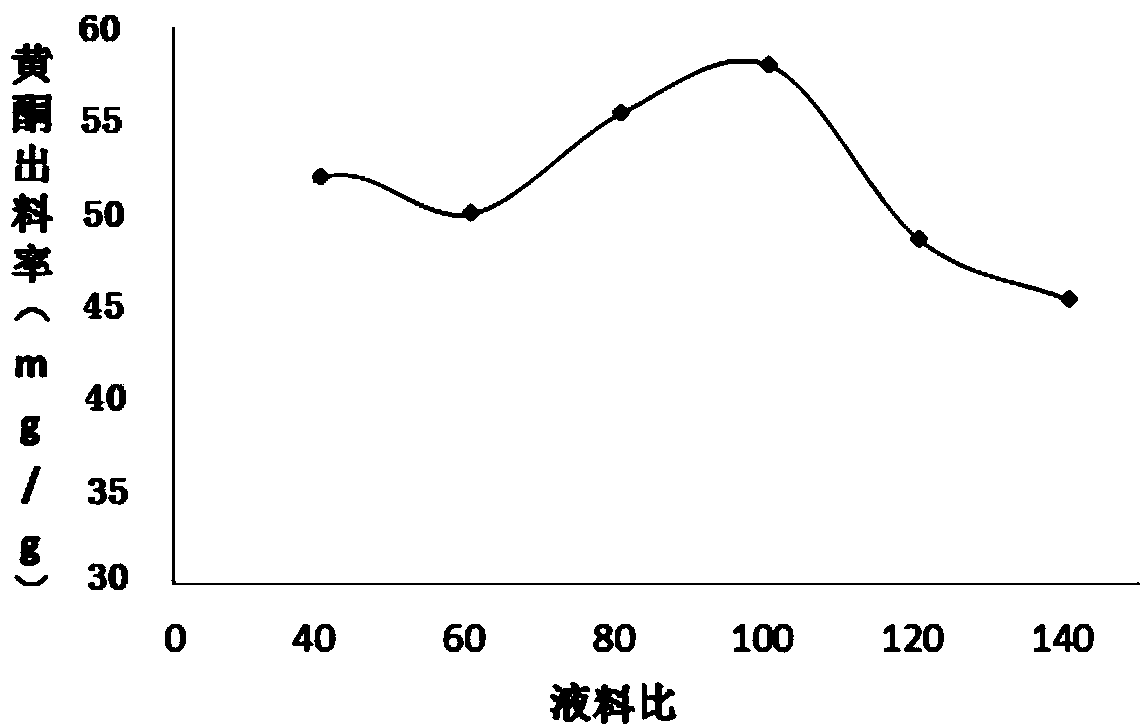

Preparation method of pine needle flavone

InactiveCN103505479AAbundant and easy to get raw materialsLow costAntinoxious agentsConiferophyta medical ingredientsDPPHSolvent

The invention discloses a preparation method of pine needle flavone, which comprises the steps that pine needle drying powder is added to a citric acid-sodium citrate buffer solution; ultrasonic enzymolysis is performed by cellulase; hemicellulase is added for the ultrasonic enzymolysis; high-temperature inactivation is performed; an alcohol aqueous solution is added for extraction; the alcohol-containing final mass concentration of an obtained extracting solution after the alcohol aqueous solution is added is 50%; the extraction is performed for 90-150min at 70-90 DEG C; centrifugation and filtering are performed; a filtrate is concentrated; a solvent is removed; and pine needle flavone is prepared. According to the preparation method, a yield of a natural flavonoid substance obtained after pine needle with the particle size of 150-200 meshes is prepared by sequential cellulase and hemicellulase treatment and an ultrasonic technology; an antioxidation effect is good; an extraction yield can reach 73.86mg / g; and the hydroxy radical and DPPH (1,1-diphenyl-2-picrylhydrazyl radical) scavenging capacity and the reducing capacity are approximate to VC (vinyl chloride) with the same concentration.

Owner:CHINA JILIANG UNIV

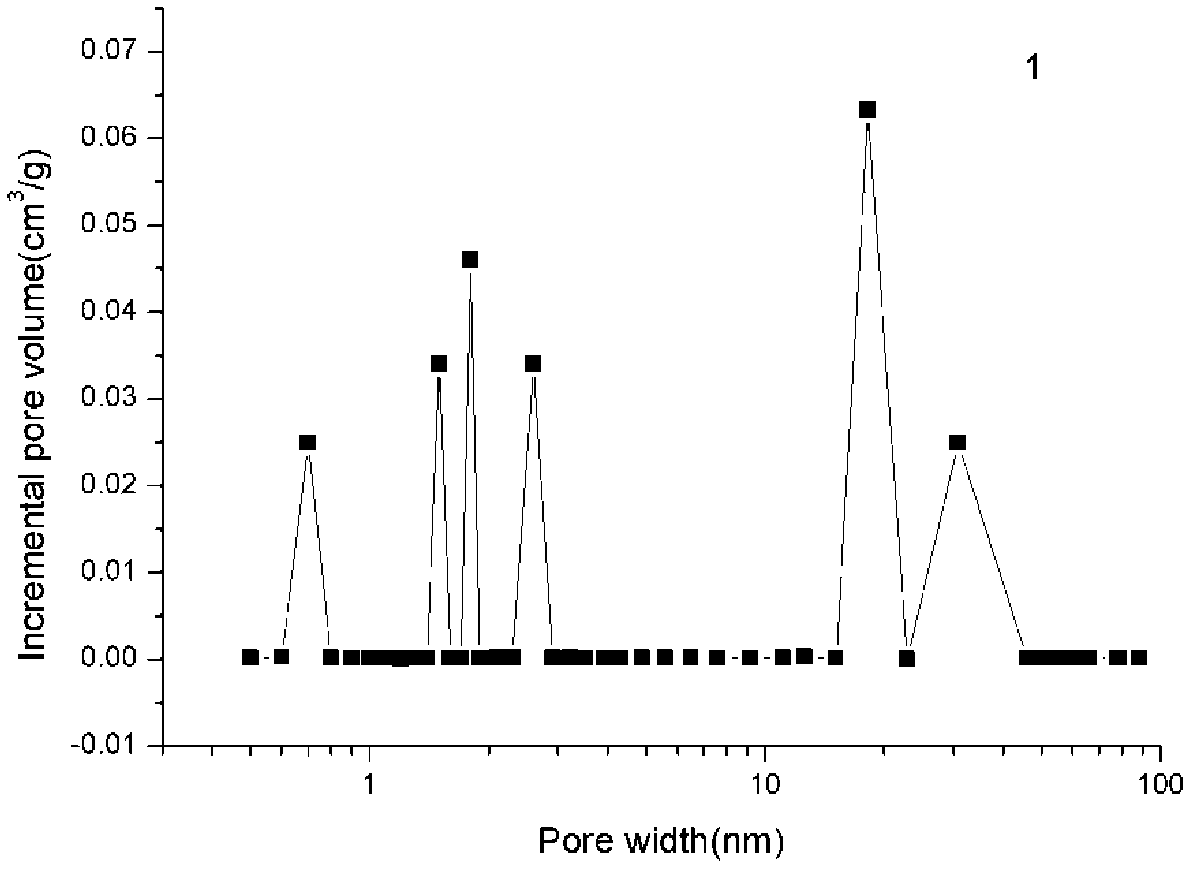

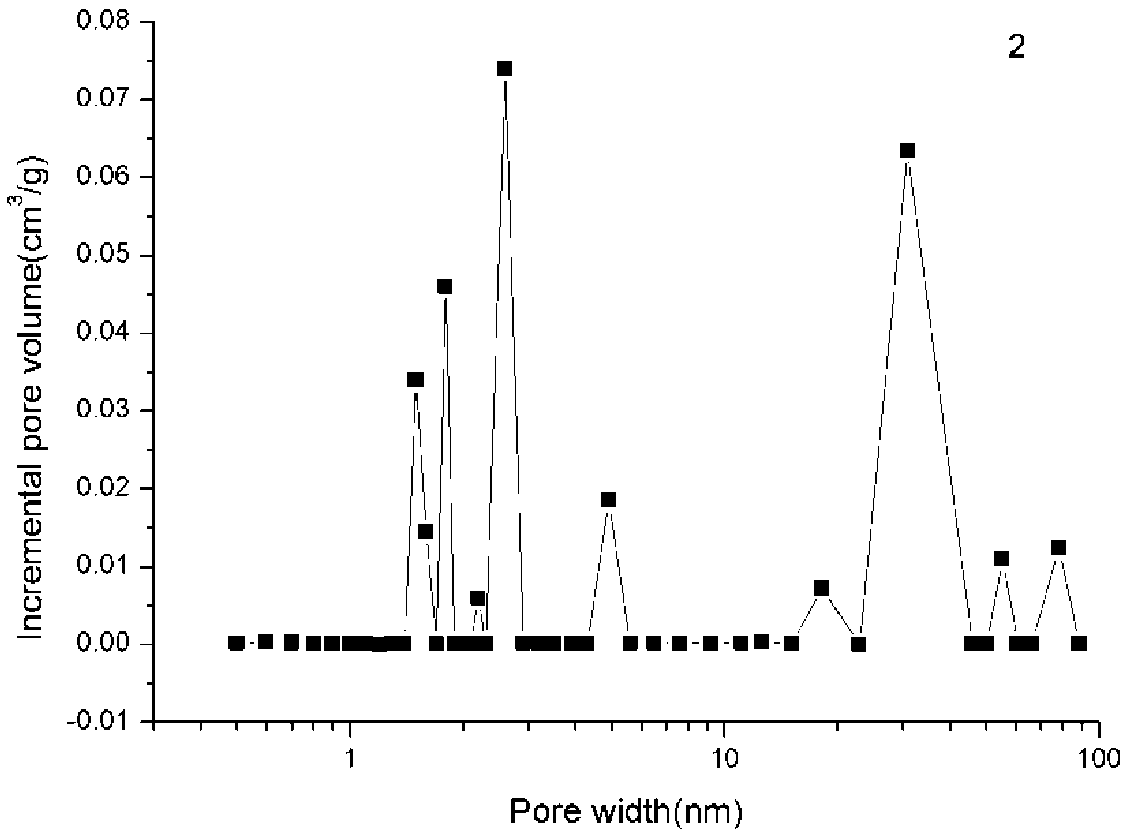

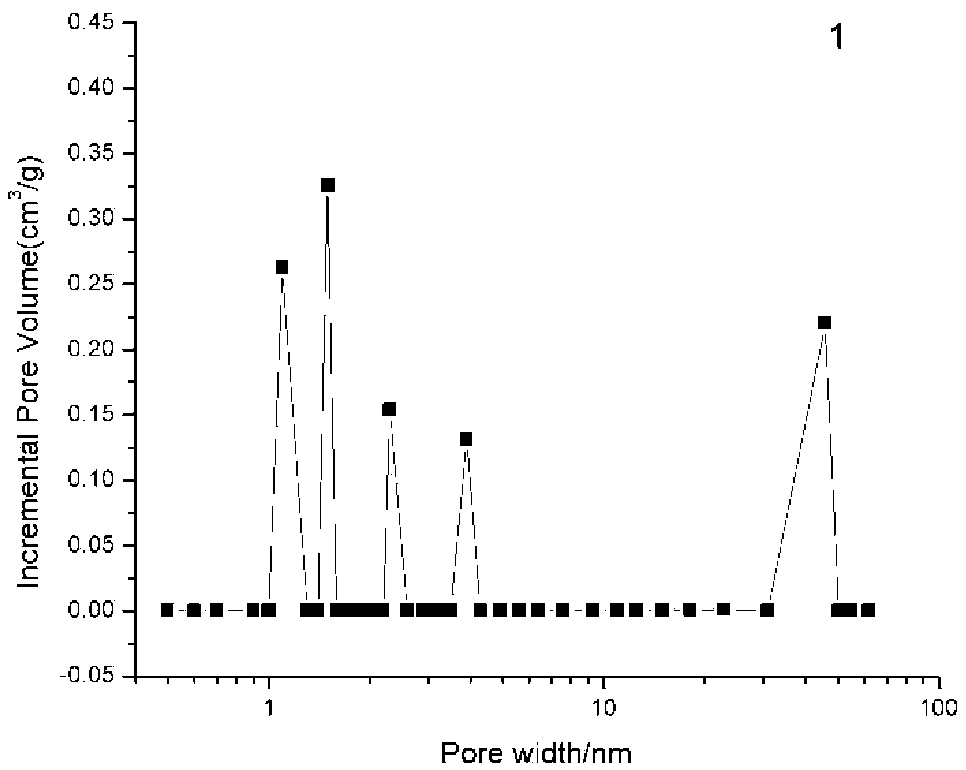

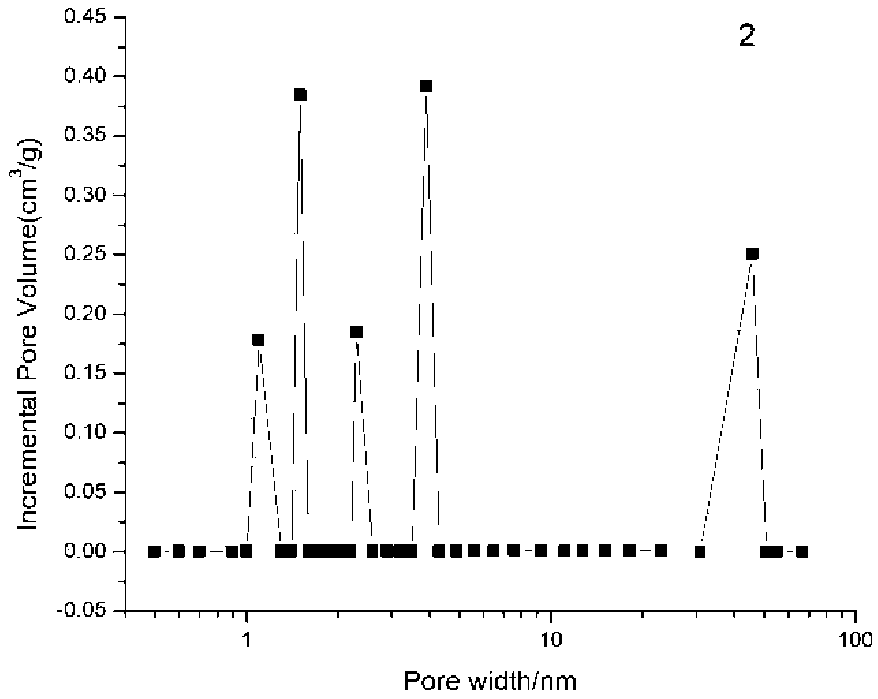

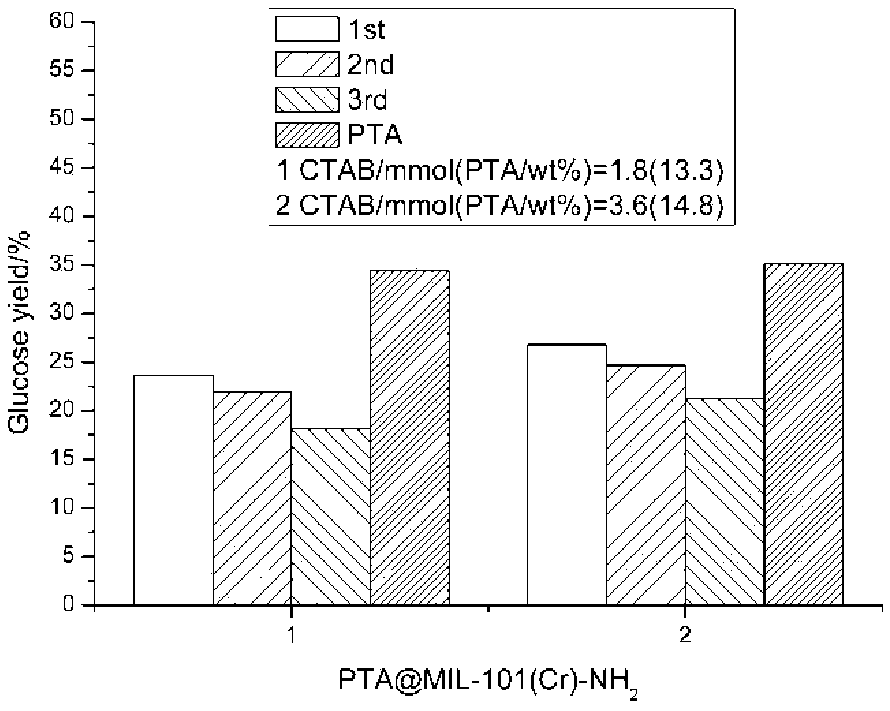

Preparation method of pore-modulatable Fe-based metal organic framework-phosphotungstic acid

ActiveCN108940366ASimple preparation processHigh material yieldOrganic-compounds/hydrides/coordination-complexes catalystsGlucose productionSolventBatch production

The invention discloses a preparation method of pore-modulatable Fe-based metal organic framework-phosphotungstic acid. The preparation method comprises the following steps: simultaneously adding FeCl3-6H2O, 2-aminoterephthalic acid, phosphotungstic acid, cetyl trimethyl ammonium bromide and TMB, mixing and stirring uniformly, carrying out a thermostatic reaction by a hydrothermal method, centrifuging, washing, and drying to obtain the pore-modulatable Fe-based metal organic framework-PTA. Pore diameter of the catalyst can be modulated within different ranges of micropores, mesopores and macropores; heat stability is good; catalytic activity is high; the preparation method is simple and is easy for batch production; there is no need to add an organic solvent or alkaline solvent in the synthesis process, and the synthesis process is green and environmentally-friendly.

Owner:SOUTH CHINA UNIV OF TECH

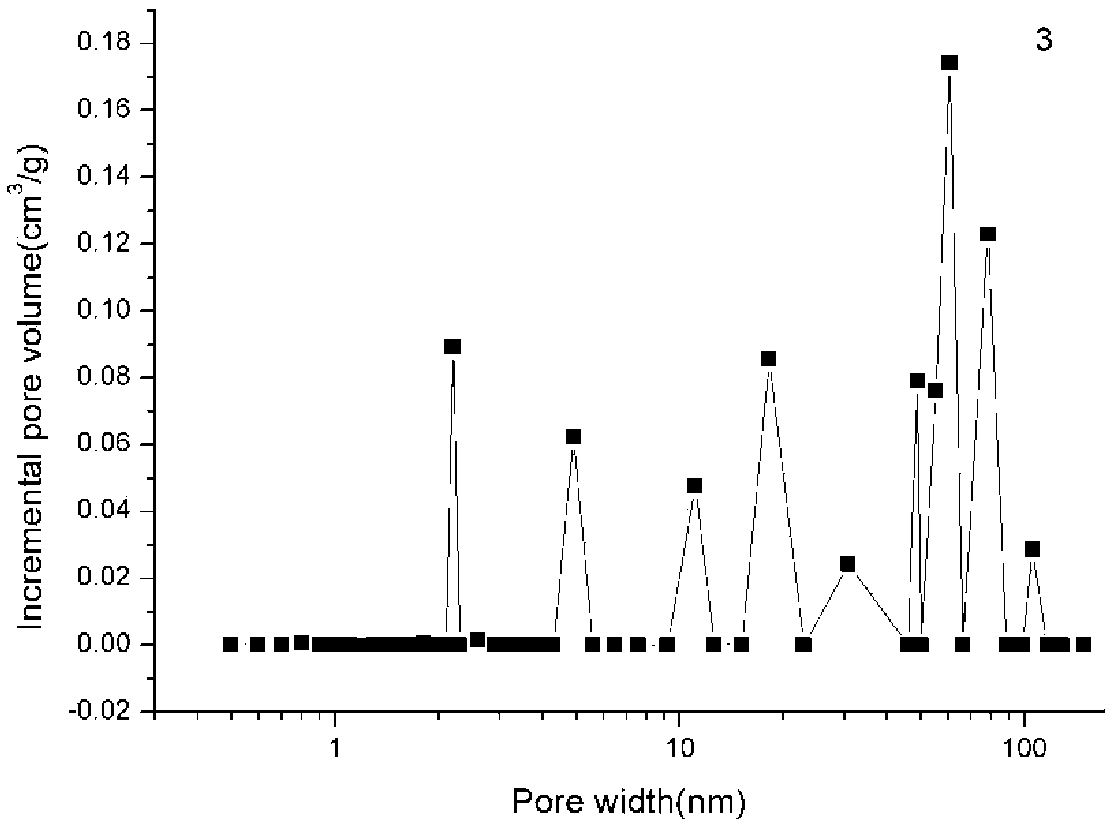

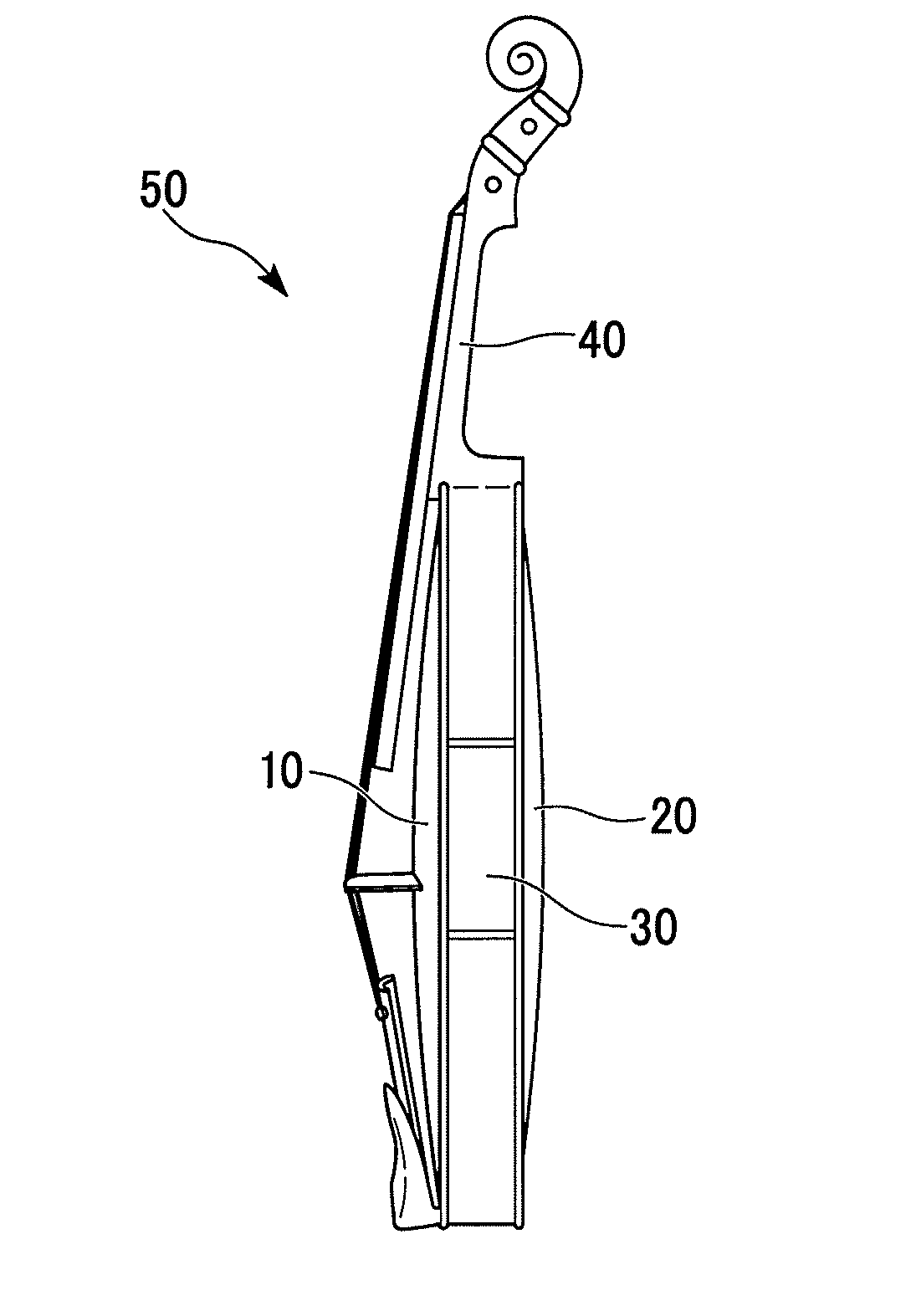

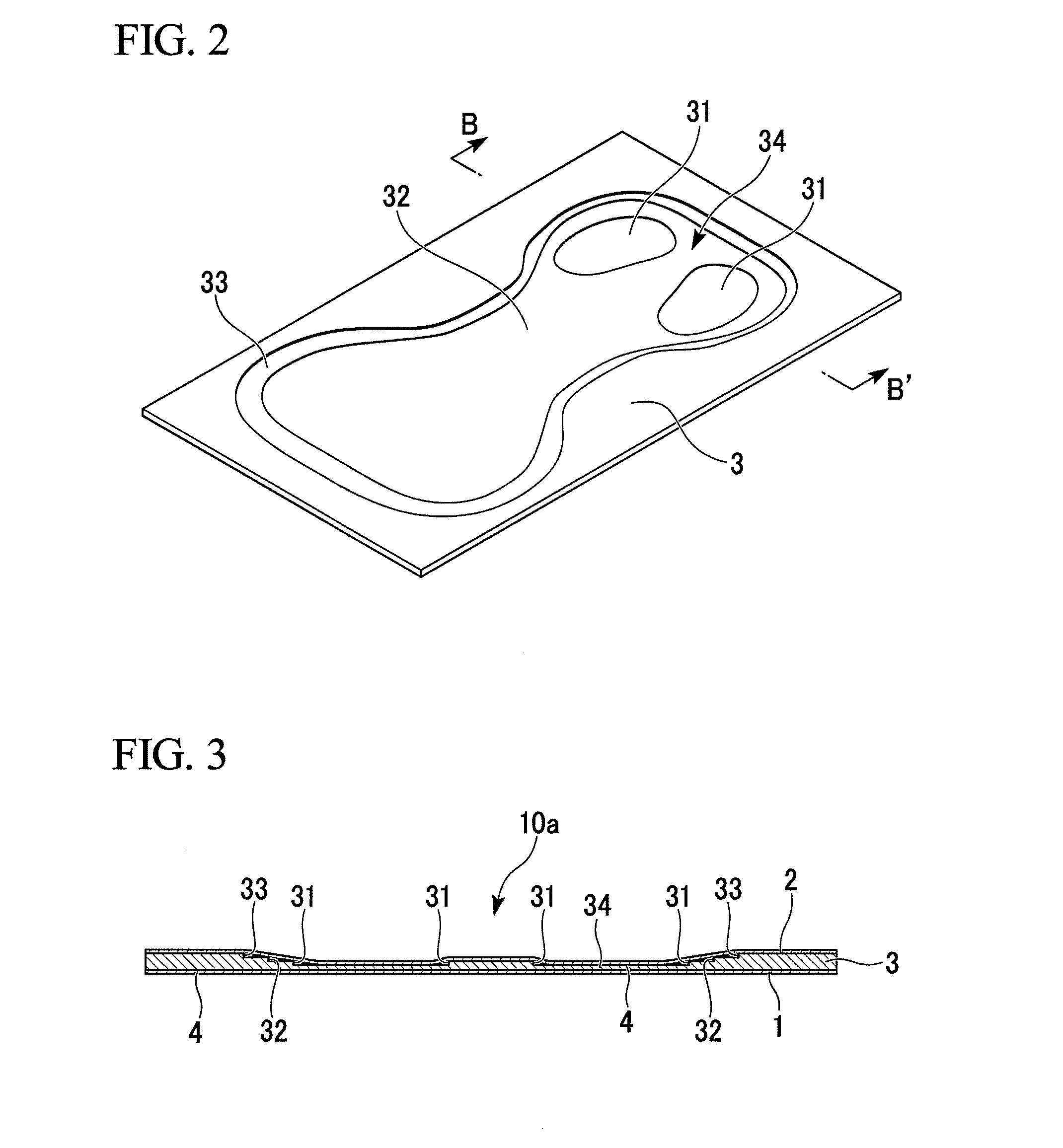

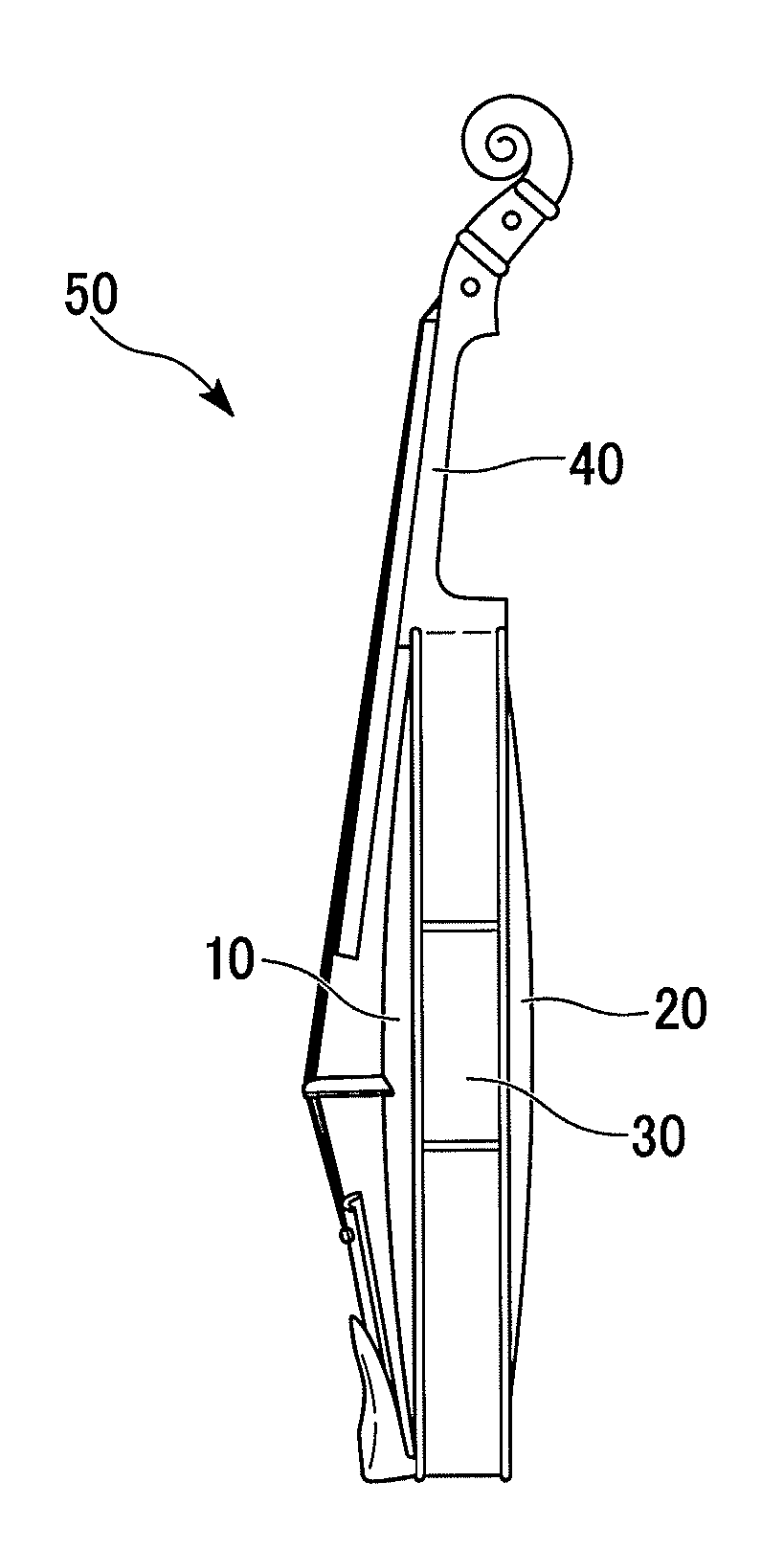

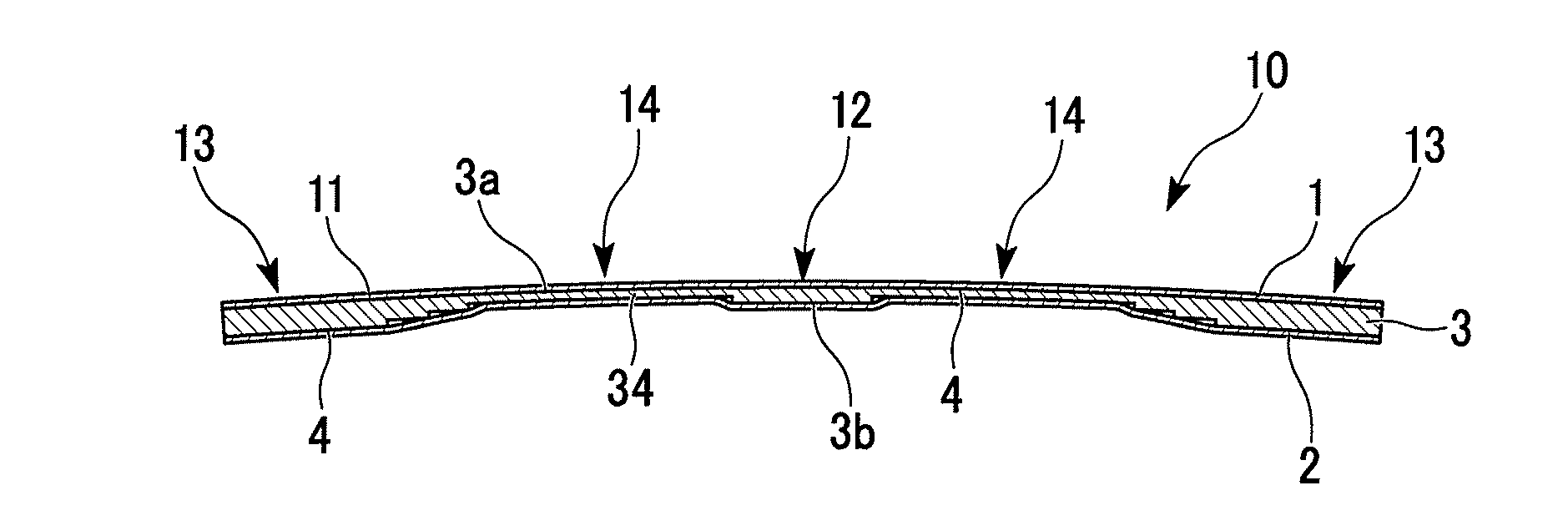

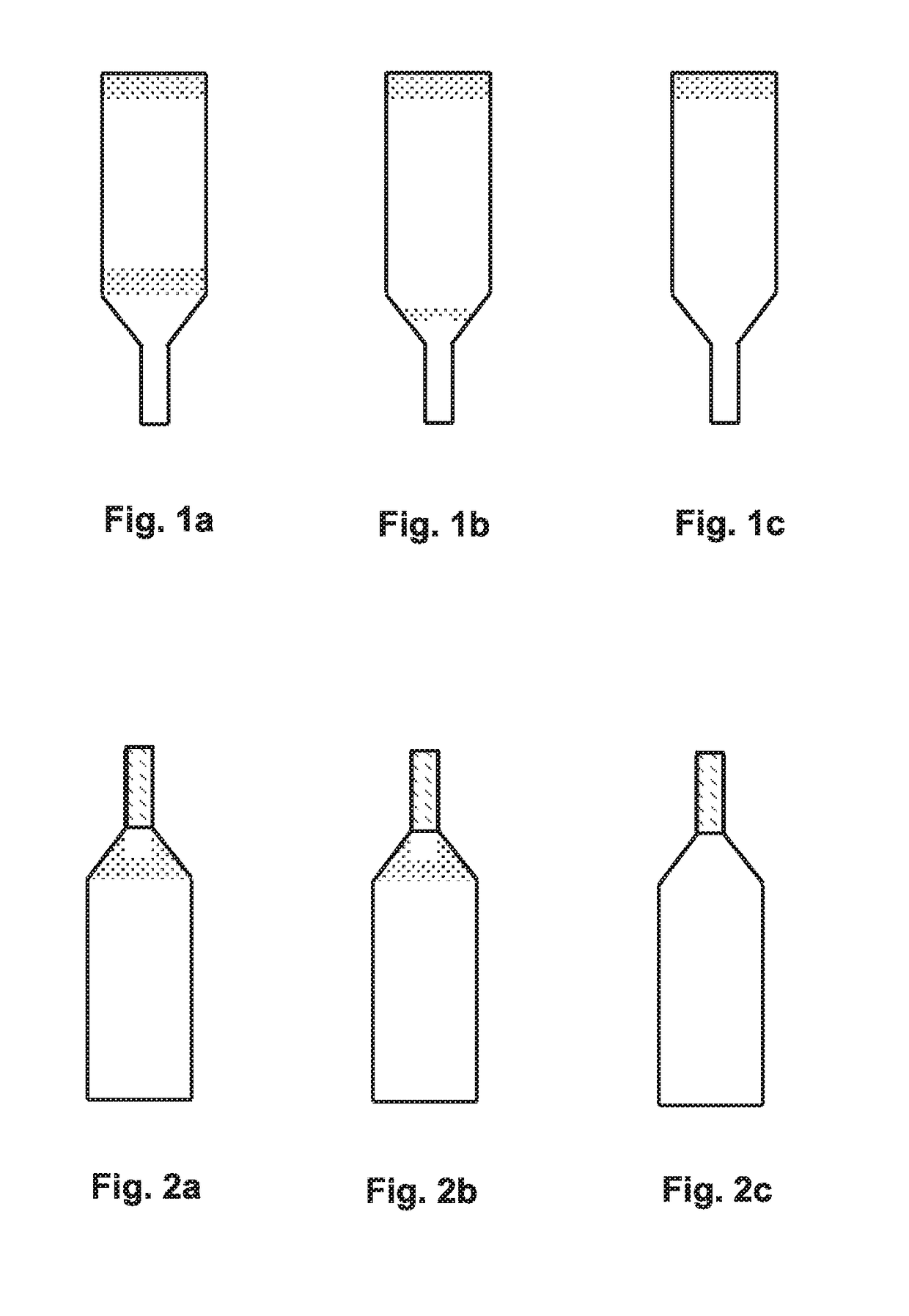

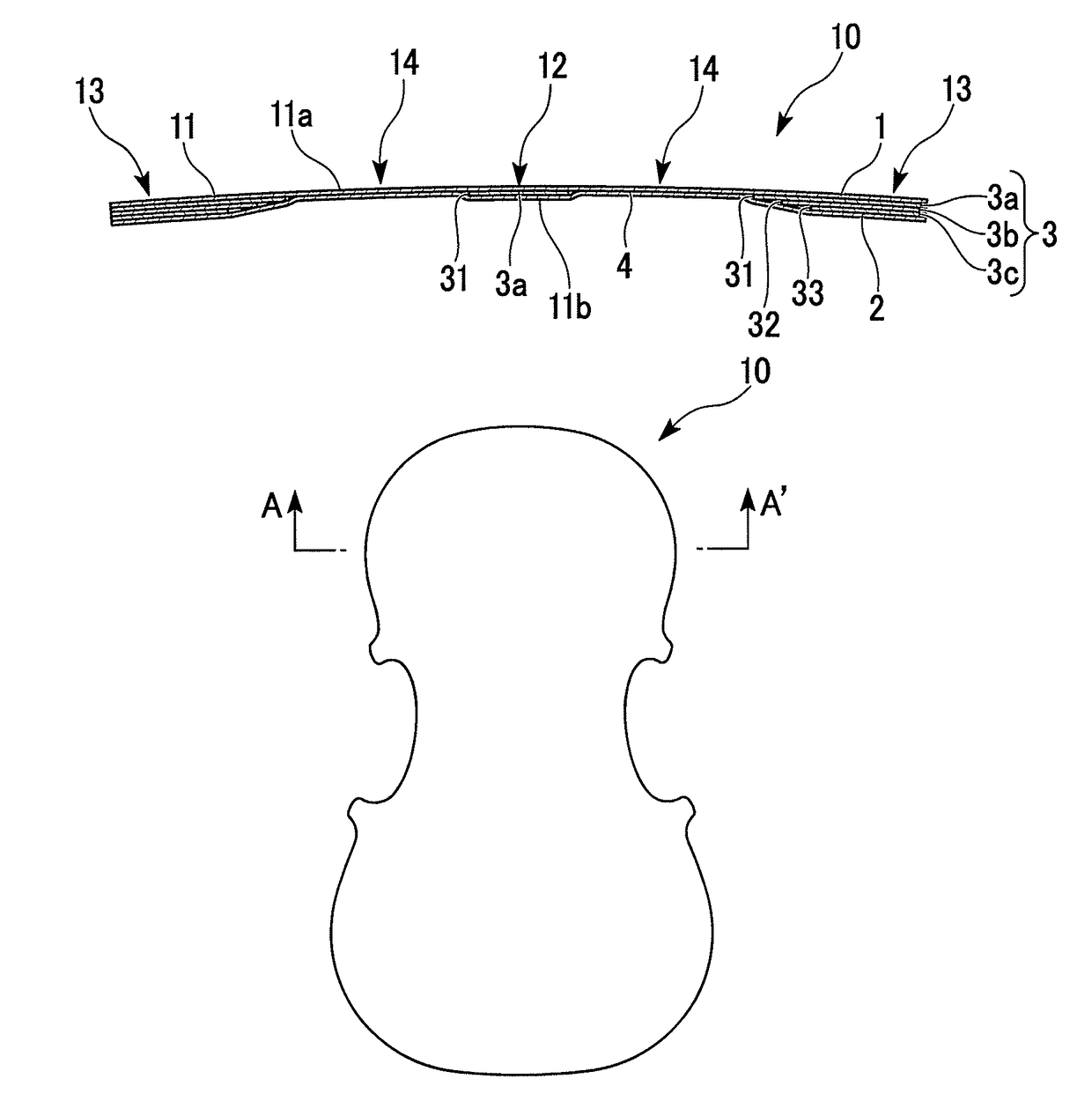

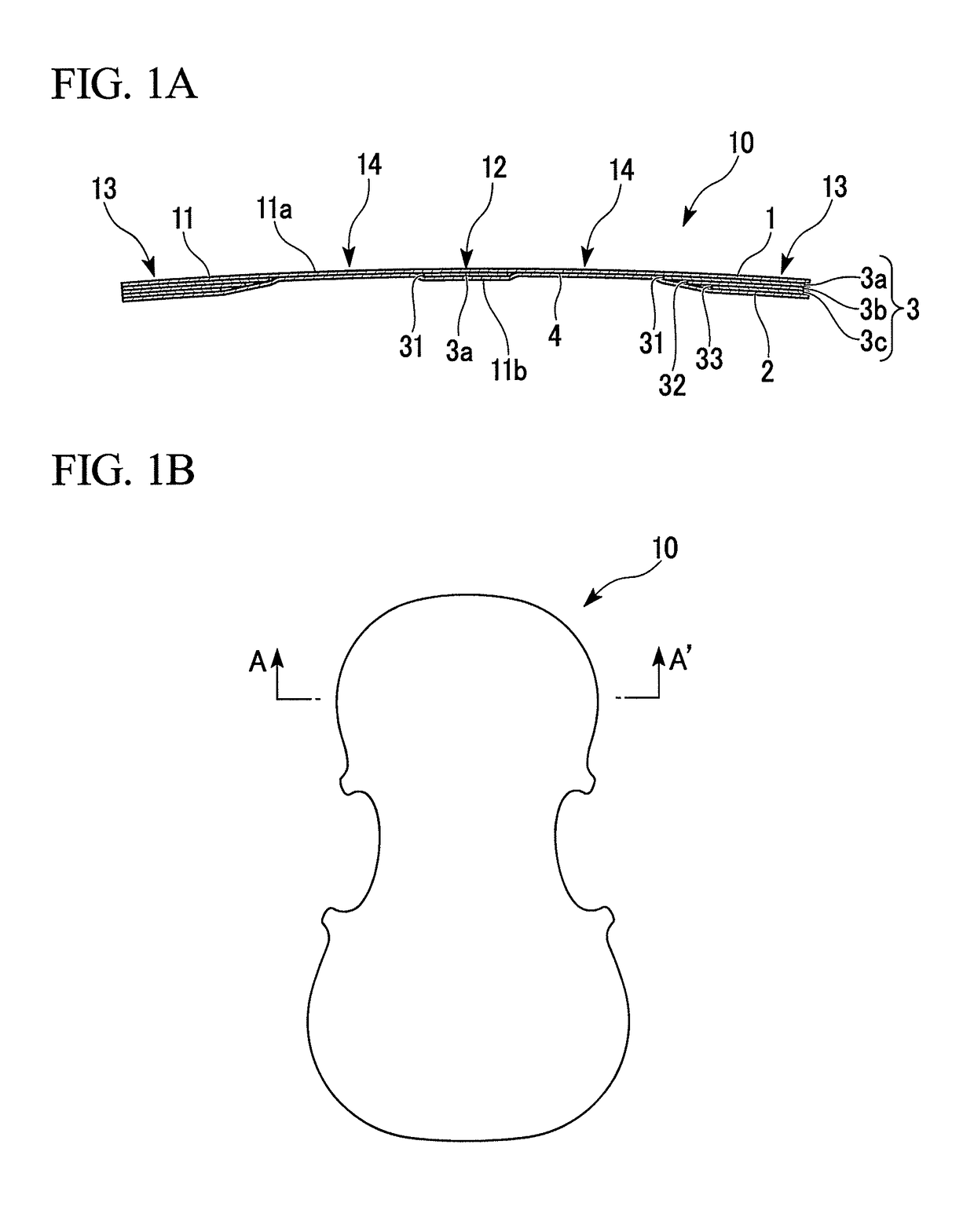

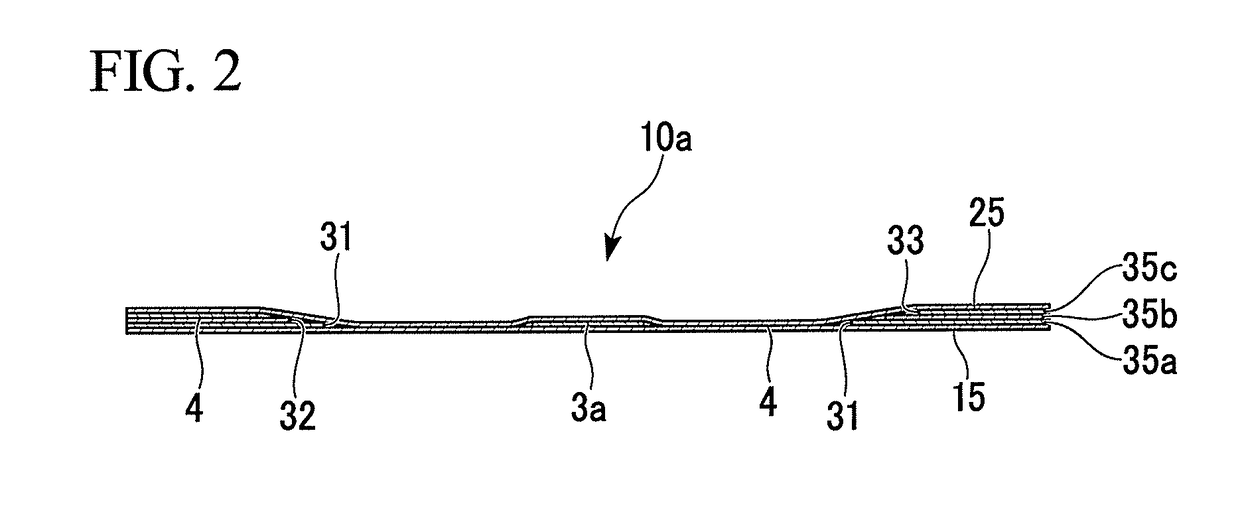

Board for stringed instrument, method of manufacturing board for stringed instrument, and stringed instrument

ActiveUS20150107434A1Reduce thicknessLittle changeElectrical transducersRecord carriersFiberEngineering

A board for a stringed instrument which forms a front plate or a back plate of a stringed instrument, includes: a veneer that includes a concave portion for partially reducing the thickness of the veneer, in which the veneer is curved to be convex toward one surface side. In this board for a stringed instrument, fiber of the veneer may extend along the curved shape of the veneer.

Owner:YAMAHA CORP

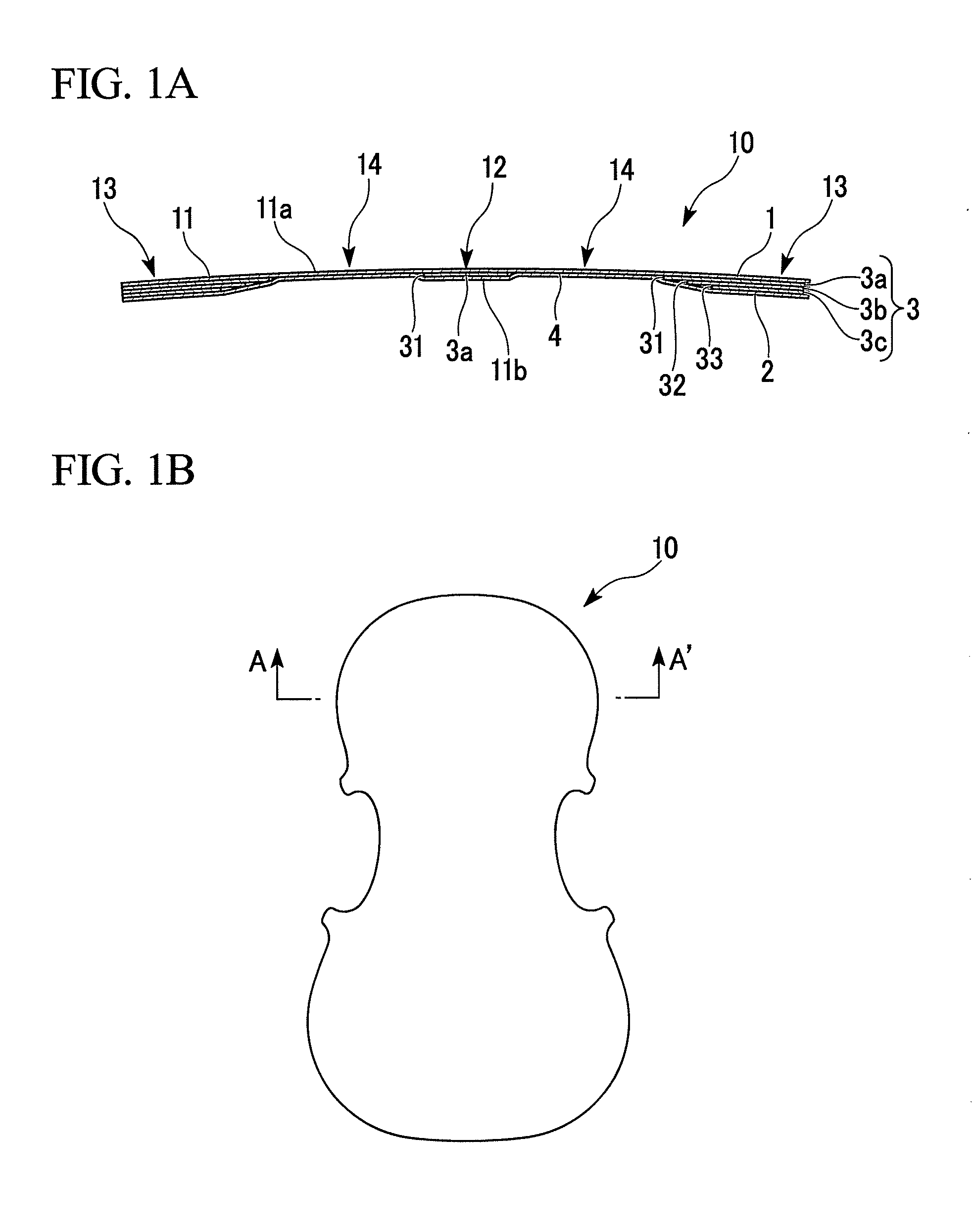

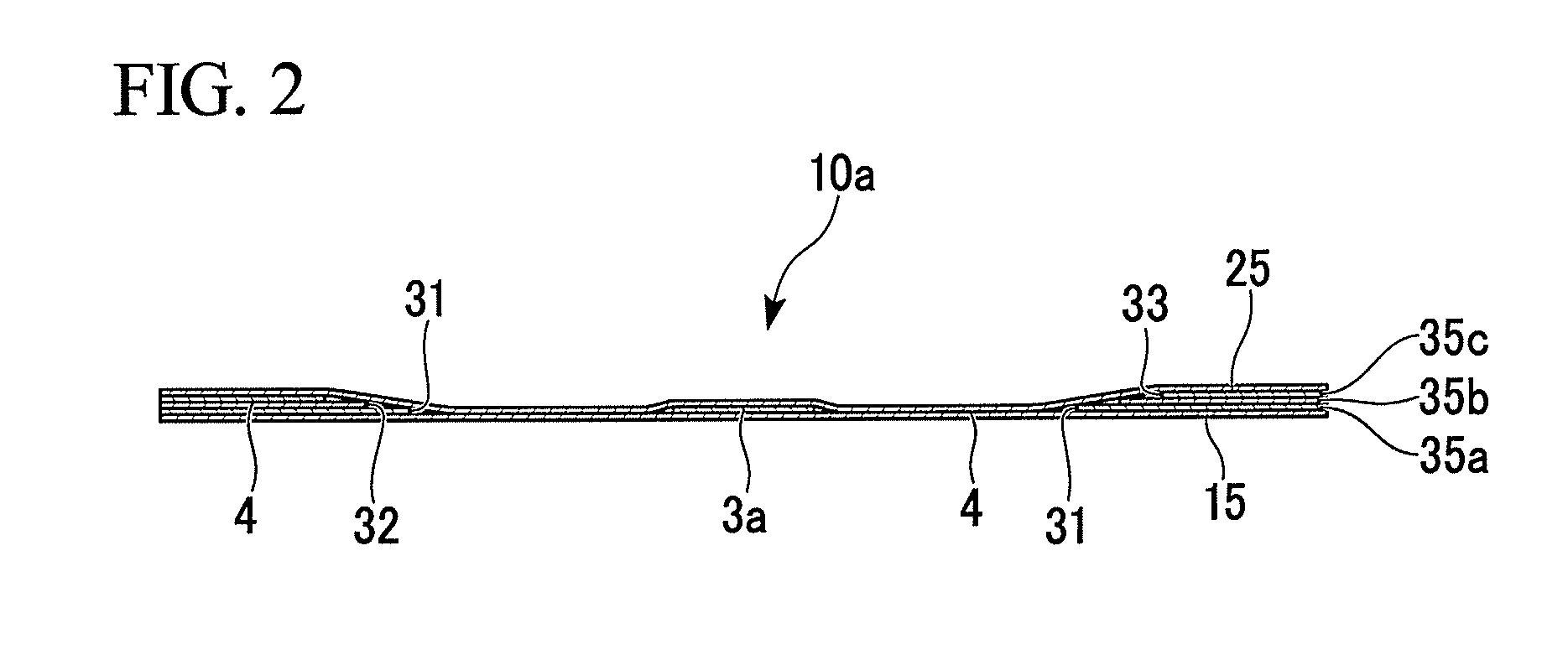

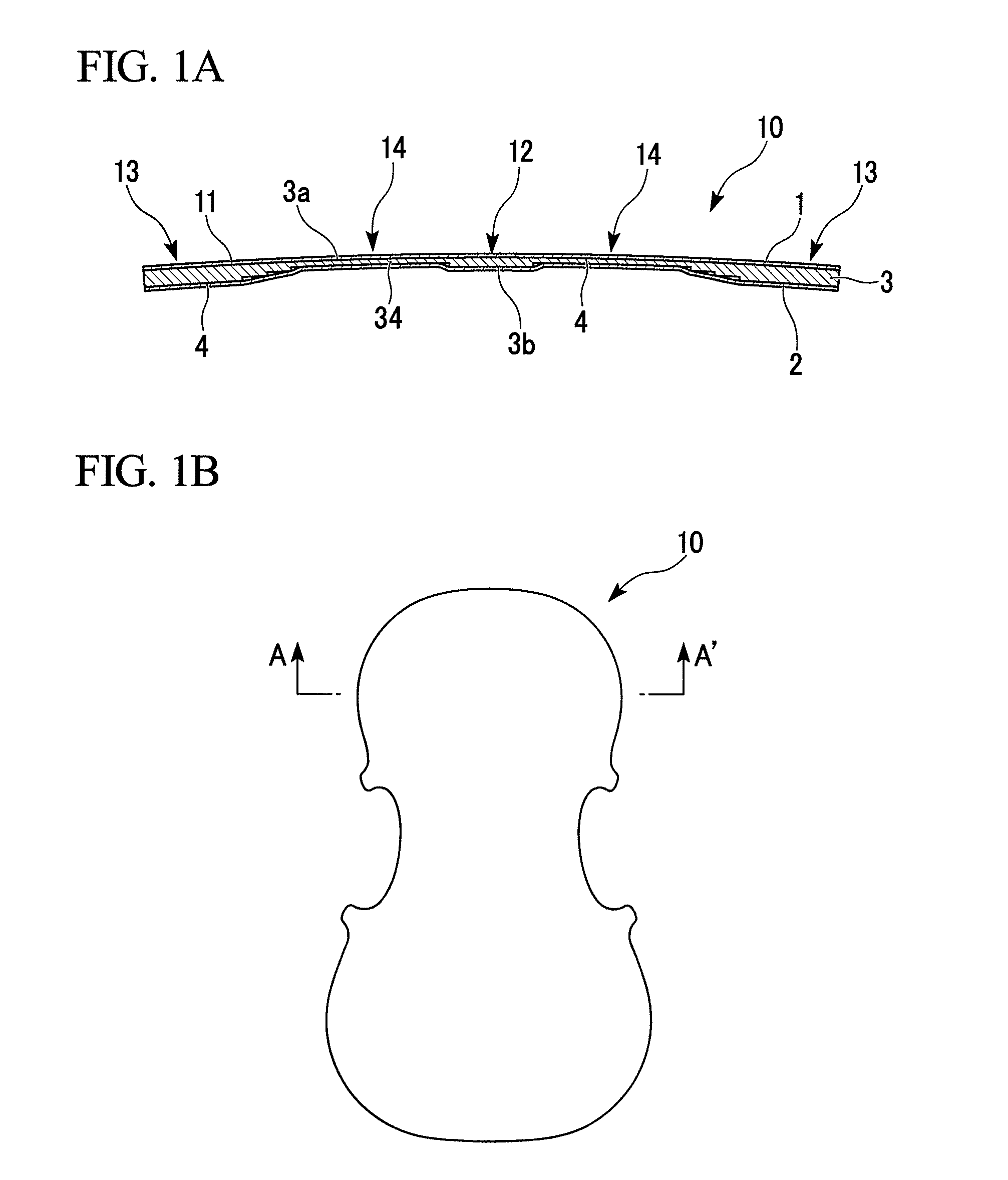

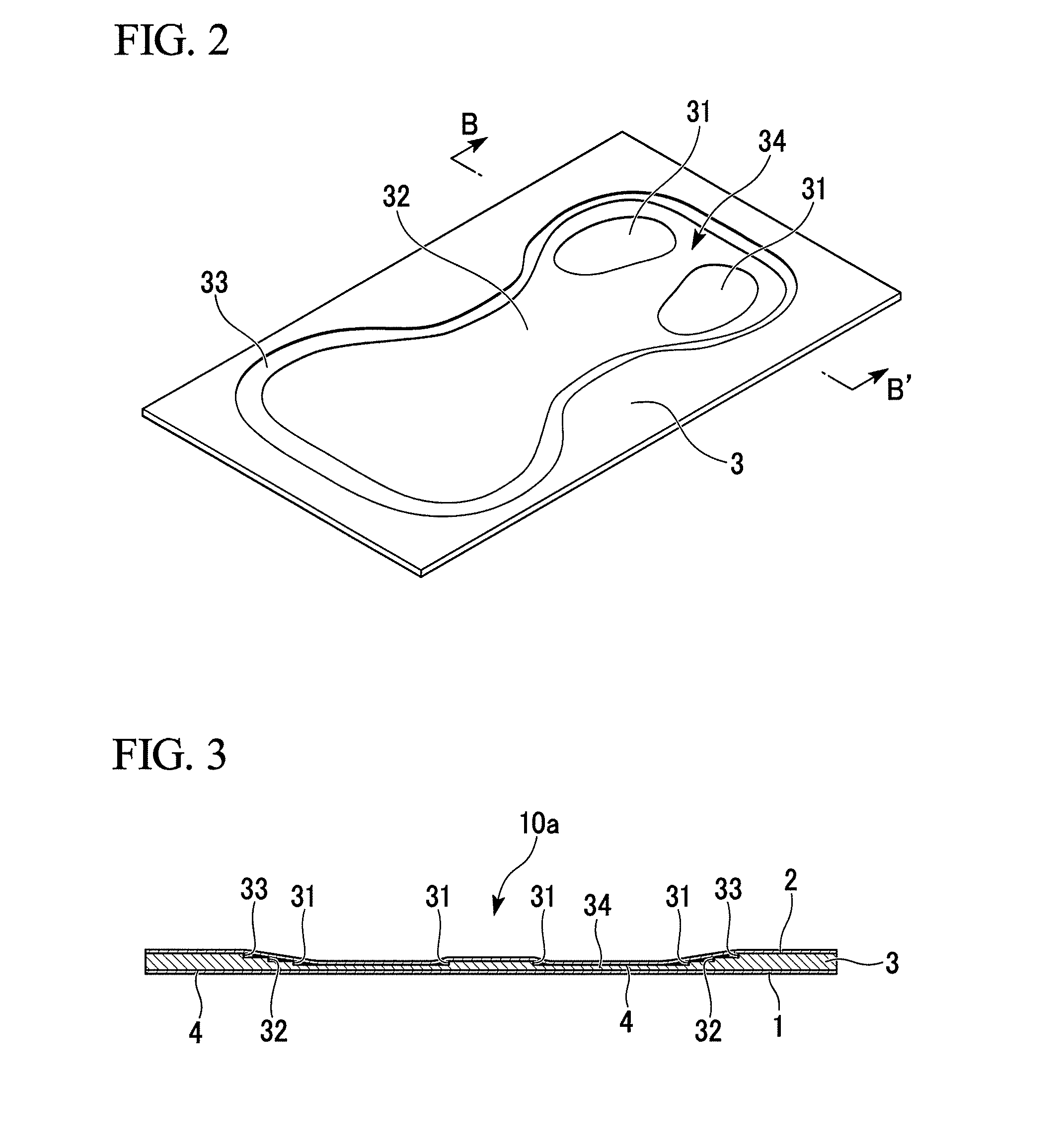

Board for stringed instrument, method of manufacturing board for stringed instrument, and stringed instrument

ActiveUS20150107435A1Little changeUnique vibrationElectrical transducersRecord carriersThin slabAdhesive

A board for a stringed instrument which forms a front plate or a back plate of a stringed instrument, includes: a laminated plate that is obtained by laminating a plurality of veneers having a uniform thickness by an adhesive, at least one of the veneers having a different planar shape than the other veneers, in which the laminated plate is curved to be convex toward one surface side and has a thin portion and a thick portion.

Owner:YAMAHA CORP

Synthesis method of mesoporous-microporous Cr-MIL-101 carrier capable of realizing synchronous immobilizing of phosphotungstic acid

ActiveCN108927220ASimple preparation processHigh material yieldOrganic-compounds/hydrides/coordination-complexes catalystsGlucose productionSolventVacuum drying

The invention discloses a synthesis method of a mesoporous-microporous Cr-MIL-101 carrier capable of realizing synchronous immobilizing of phosphotungstic acid. The synthesis method comprises following steps: distilled water, 2-aminoterephthalic acid, Cr(NO3)3-9H2O, PTA, and CTAB are mixed to be uniform using magnetic stirring, an obtained mixture is heated for 10 to 14h at a constant temperatureof 130 to 170 DEG C, an obtained product is cooled to room temperature through natural cooling, and is subjected to centrifugation; an obtained solid substance is washed repeatedly with DMF and ethanol until the supernatant of centrifugation is transparent, and the solid substance is subjected to vacuum drying for 15.95 to 16.05h at 78 to 82 DEG C so as to obtain the mesoporous-microporous Cr-MIL-101 carrier capable of realizing synchronous immobilizing of phosphotungstic acid. The synthesis method is simple; yield is high; the synthesis method is convenient for large scale production; no organic solution or alkaline solution is added as a solvent in synthesis process; the obtained PTA@MIL-101(Cr)-NH2 is excellent in water stability and heat stability.

Owner:SOUTH CHINA UNIV OF TECH

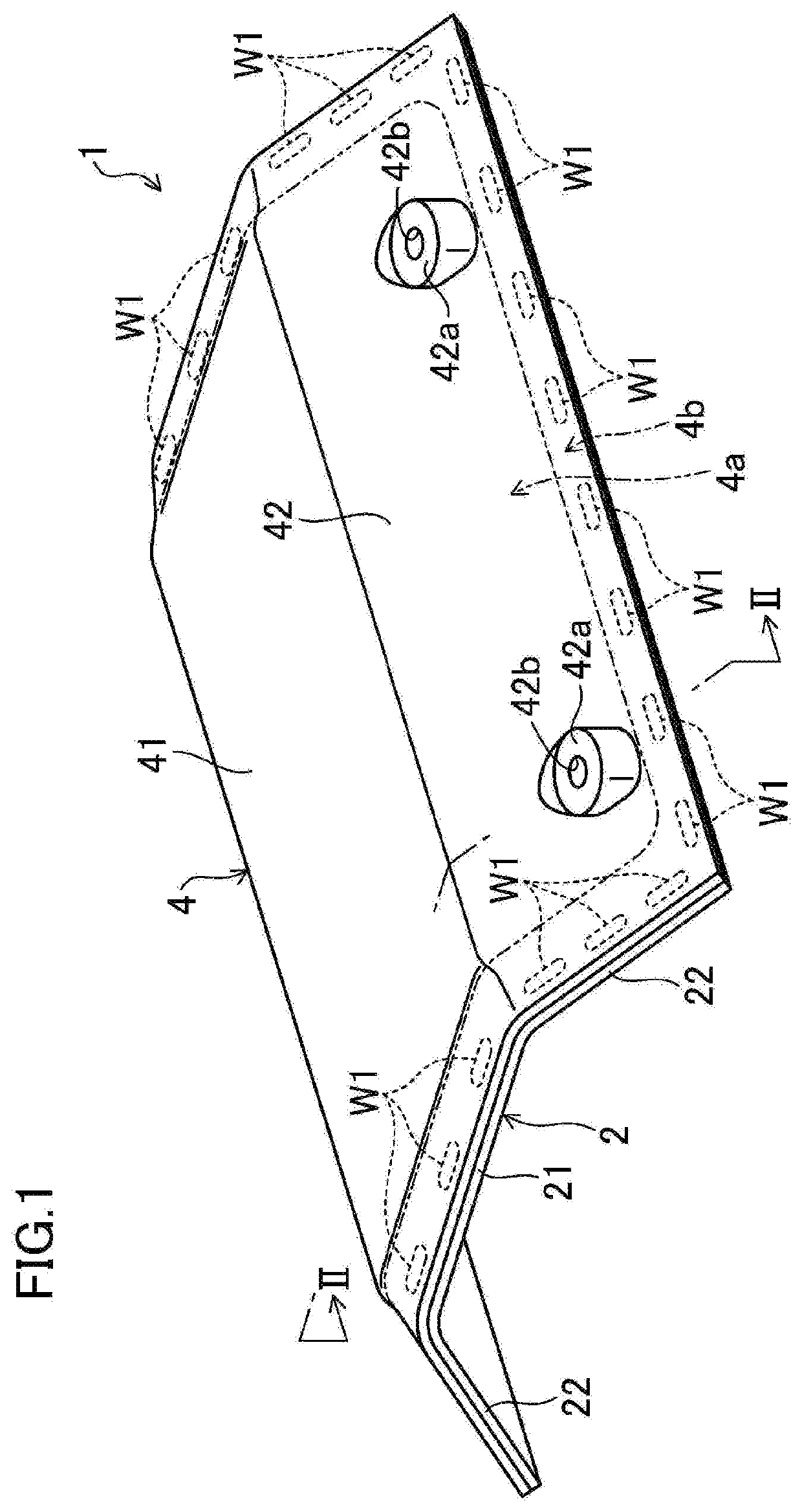

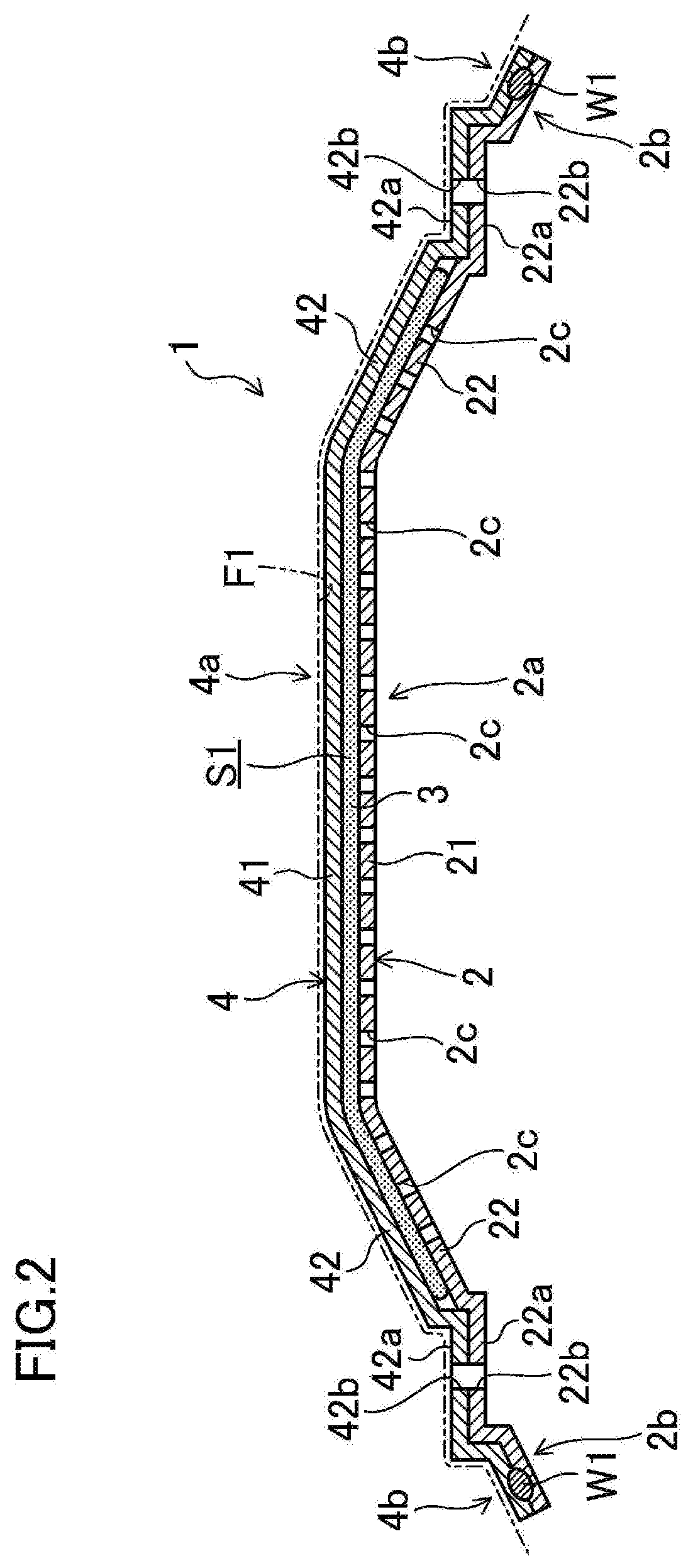

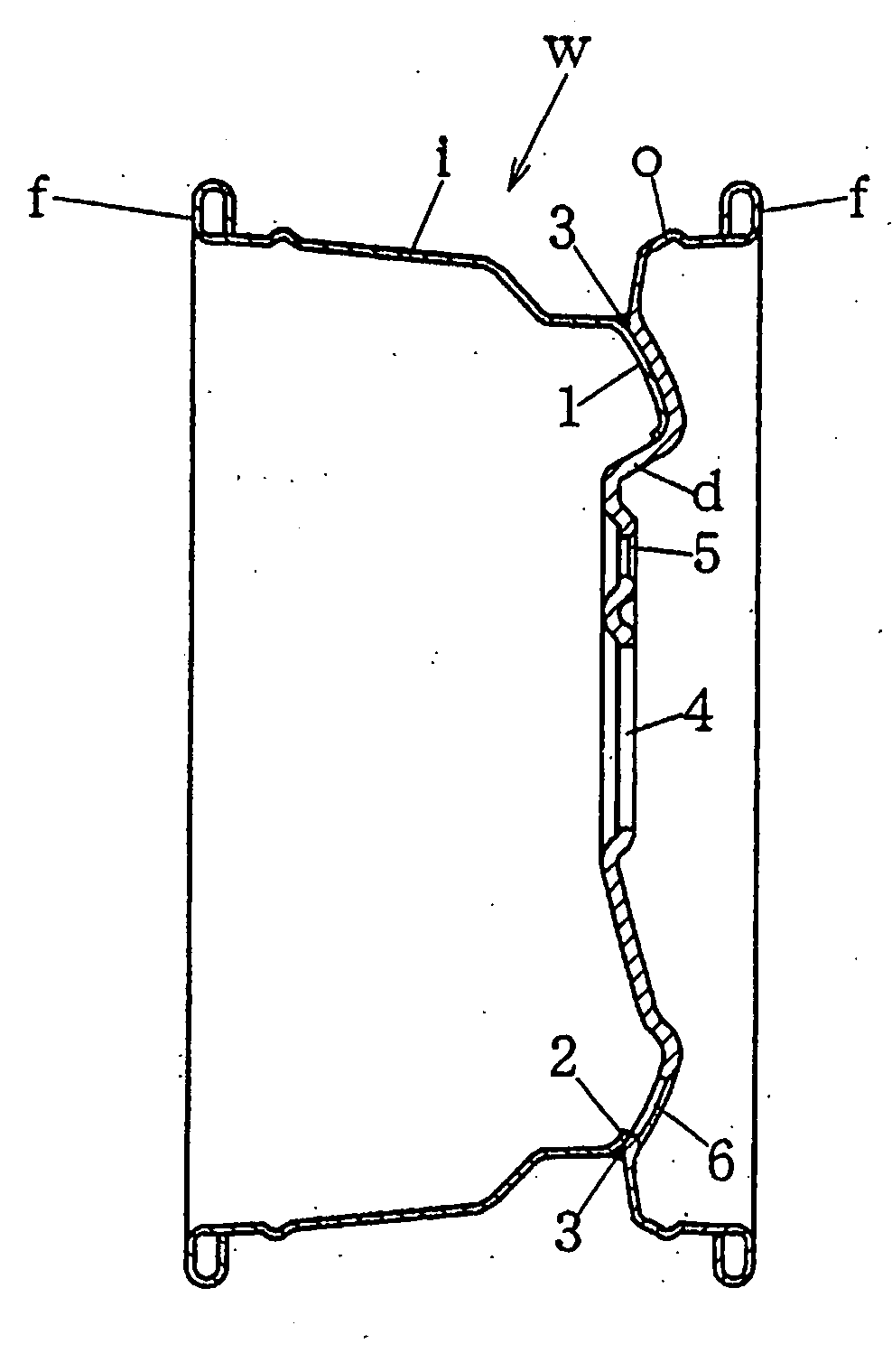

Insulator

ActiveUS20200207062A1Improve material yieldReduce weightMachines/enginesVehicle componentsEngineeringGlass wool

According to the present invention, a panel-shaped first metal body (2) comprises a space-forming part (2a) and an overlap part (2b) that is continuous with the space-forming part (2a). A panel-shaped second metal body (4) comprises a space-forming part (4a) and an overlap part (4b) that is continuous with space-forming part (4a). When the first metal body (2) and the second metal body (4) have been assembled, a housing space layer (S1) that is for housing a sheet-shaped glass wool material 3 is formed between the space-forming parts (2a, 4a), and the overlap parts (2b, 4b) overlap. A solid joining part (W1) that connects the overlap parts (2b, 4b) is formed between the overlap parts (2b, 4b).

Owner:KEYLEX CORP

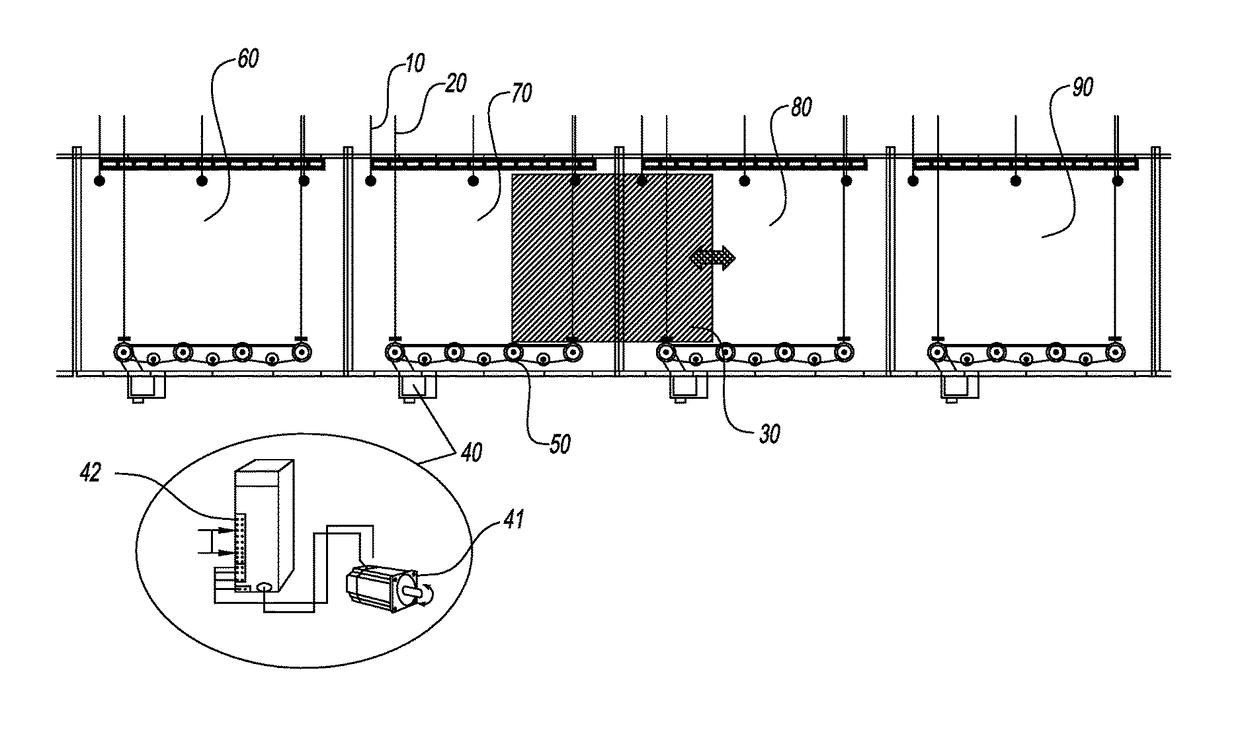

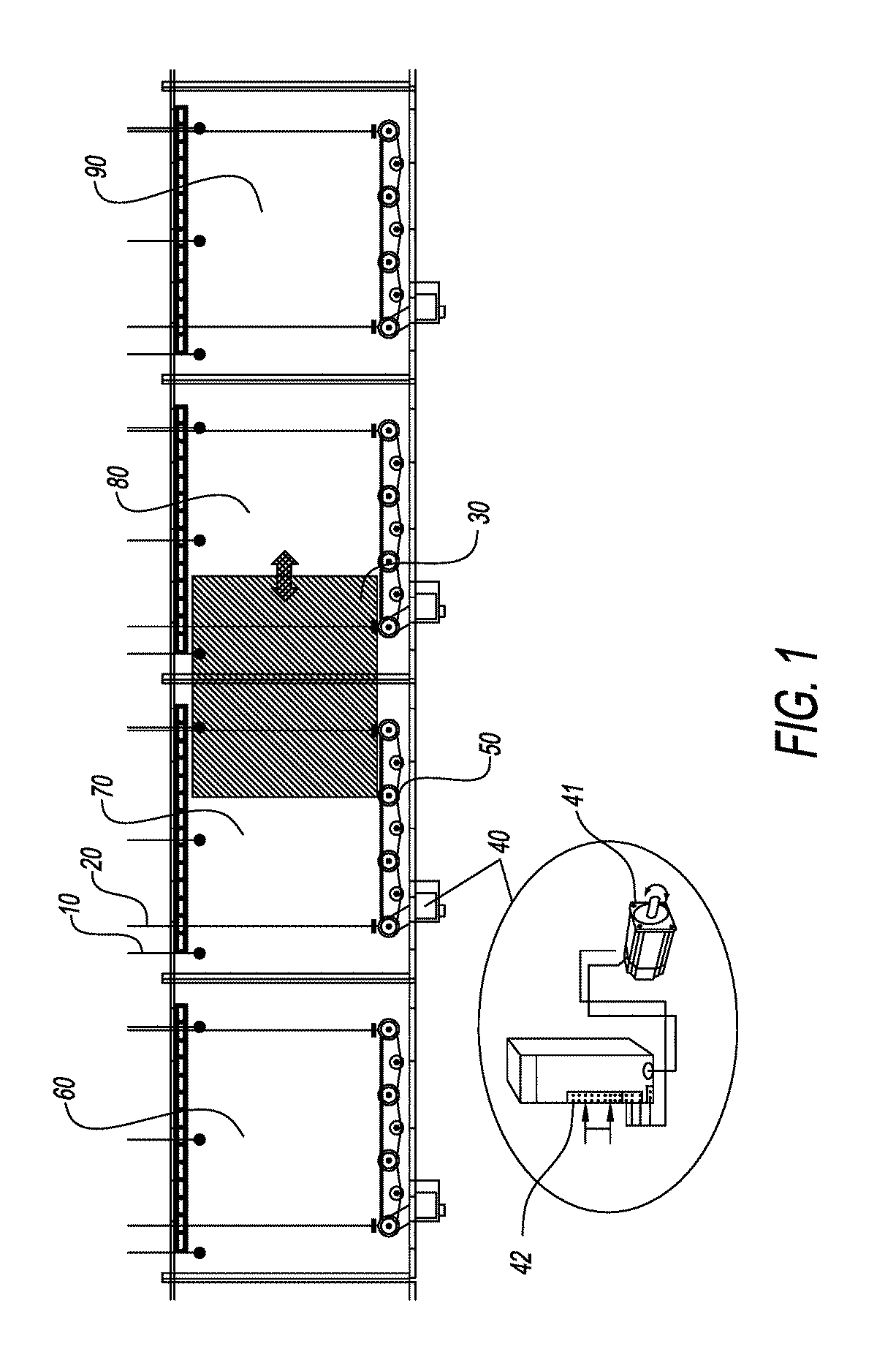

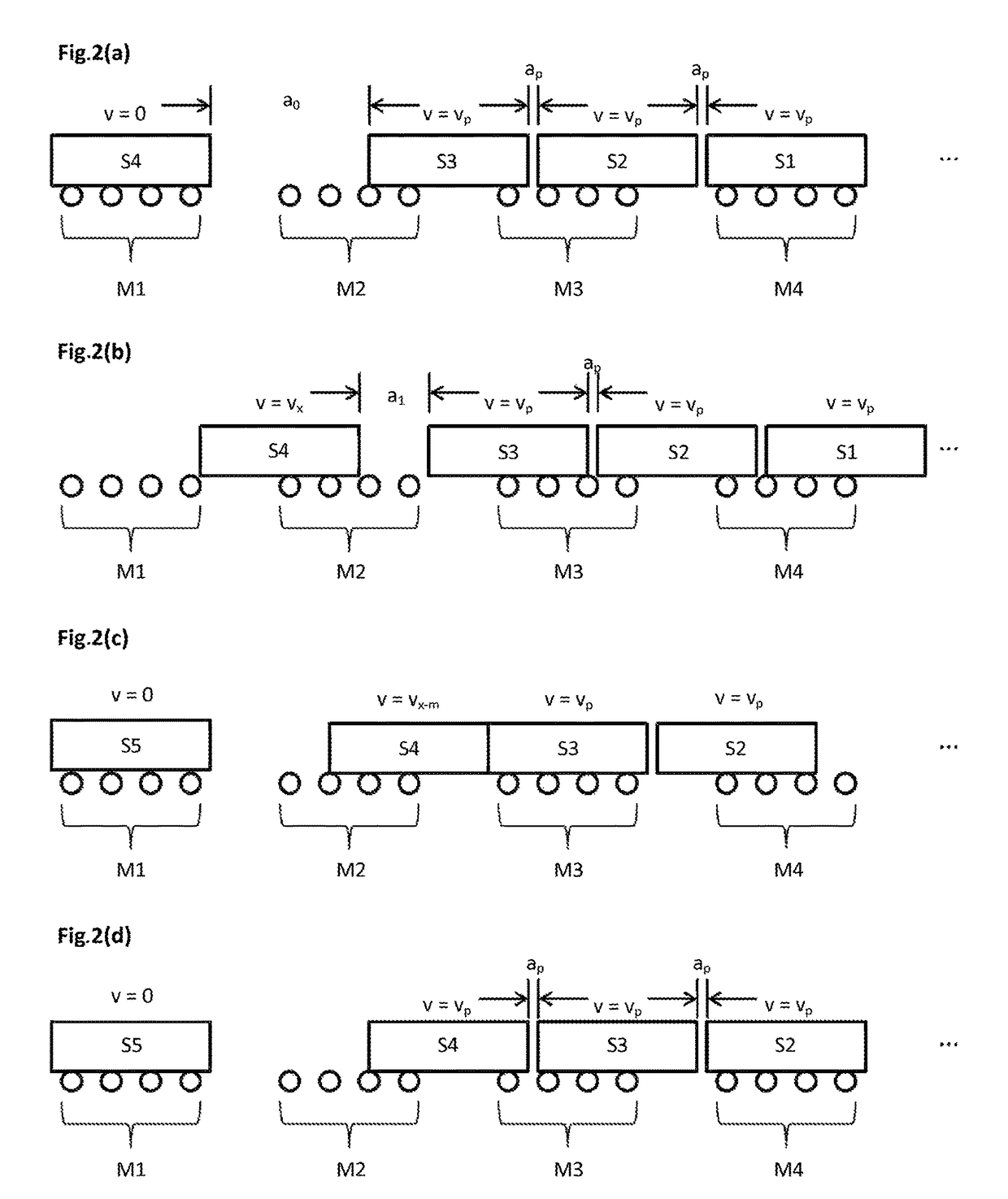

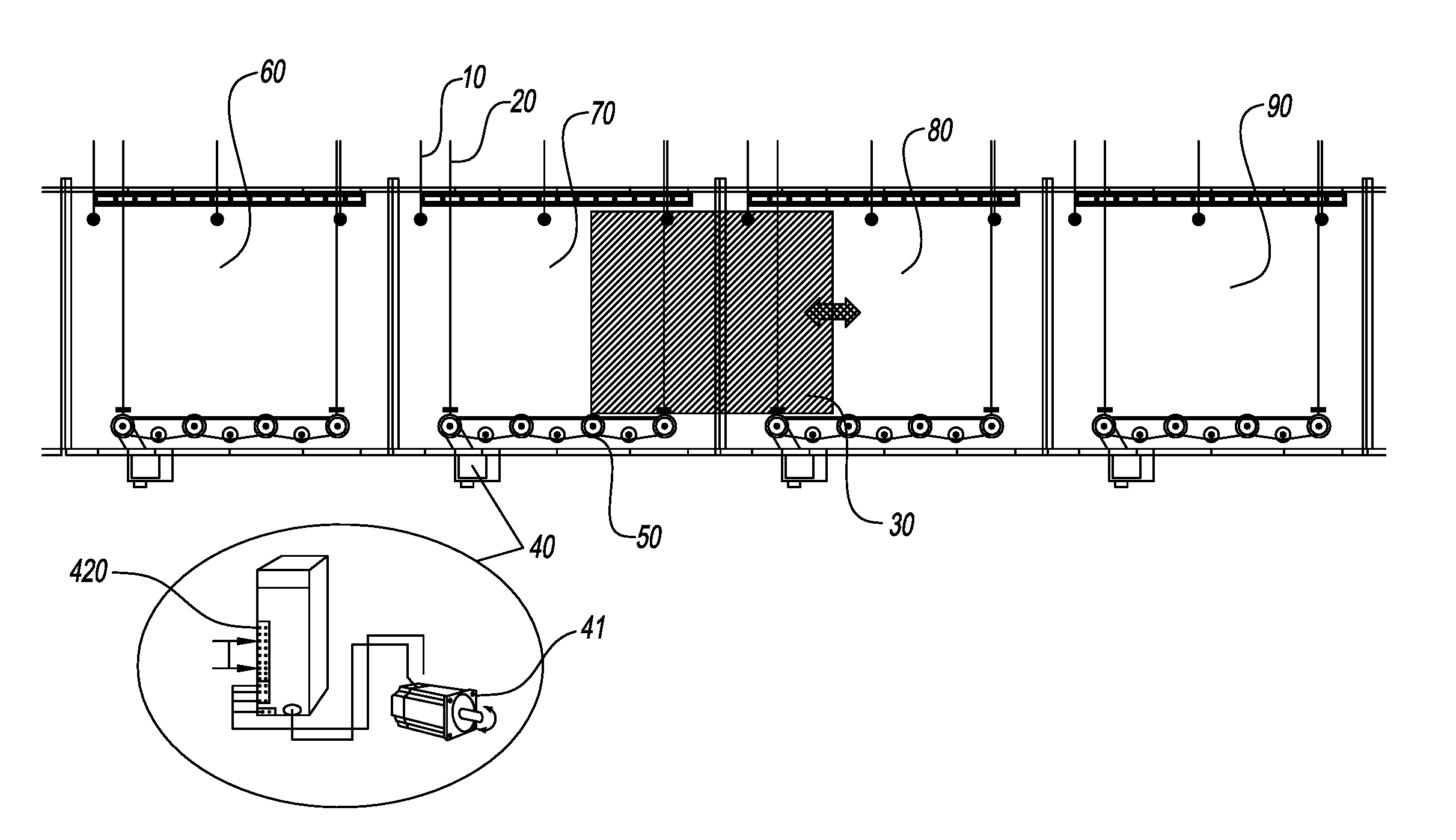

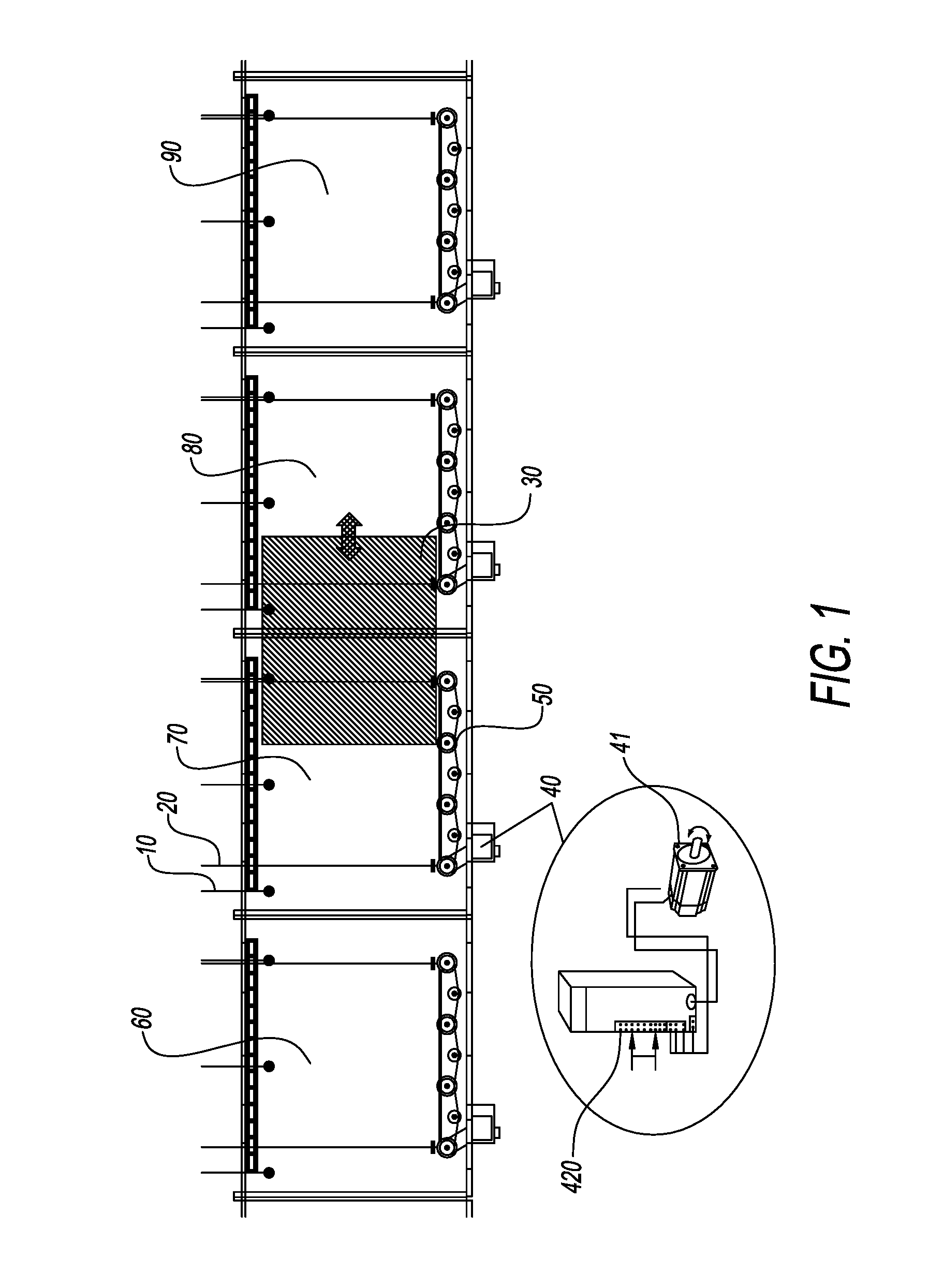

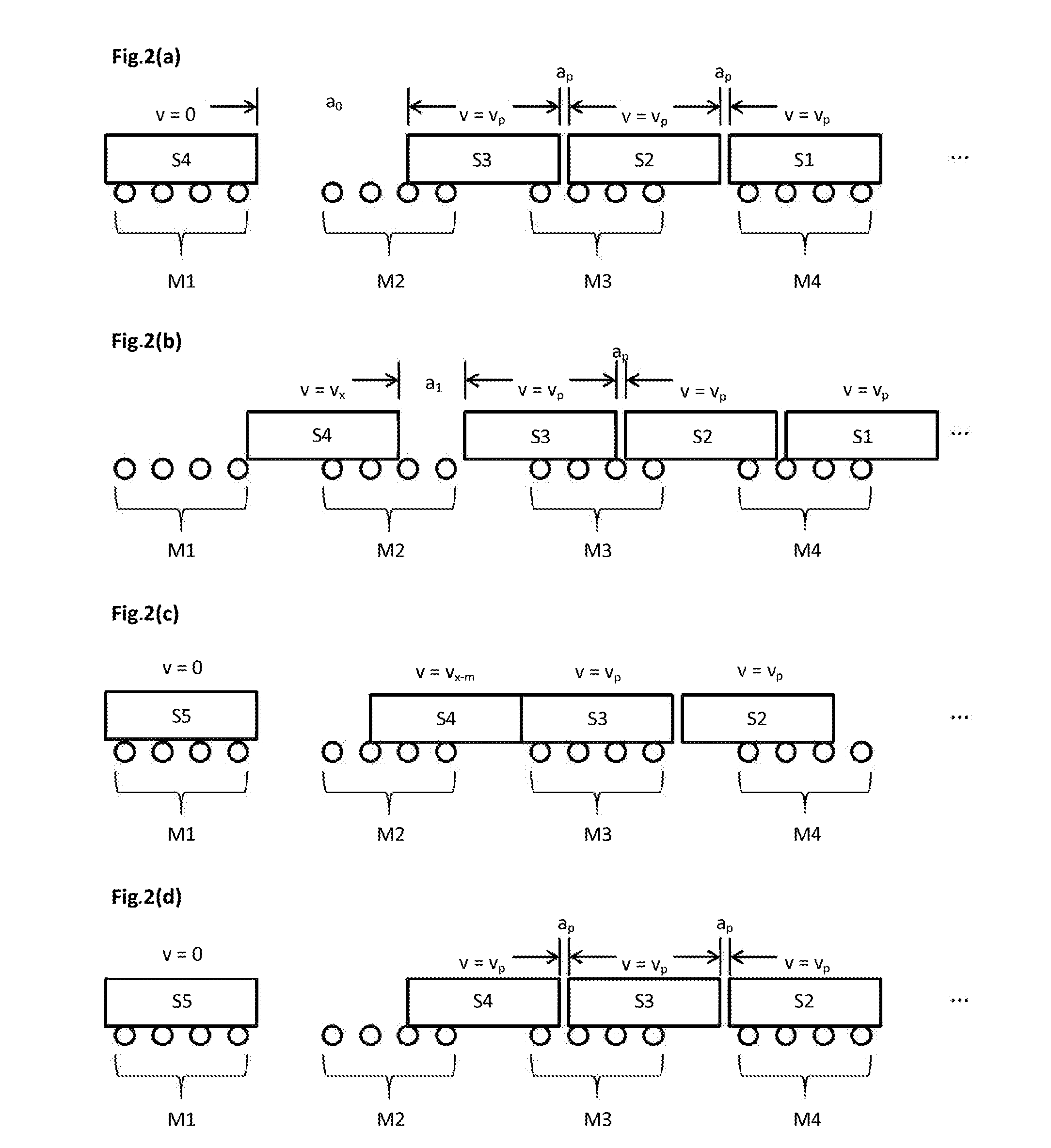

Method and device for stringing substrates together in coating systems

ActiveUS9845202B2High material yieldAvoid damageConveyorsSemiconductor/solid-state device manufacturingTransport systemEngineering

A method and a device for stringing together objects in transport systems, preferably in coating systems, for adjusting the distance between two objects, preferably substrates or substrate holders, being arranged one behind the other, wherein the front object moves at a process speed vp in the transport system and the rear object is at an undefined distance from the front object. The method comprises the following steps: (a) accelerating the rear substrate to an initial speed vx>vp; (b) detecting an increase in the driving torque when the rear substrate moves against the front substrate; (c) delaying the rear substrate by a predetermined value in order to establish a predetermined distance ap from the front substrate; and (d) adjusting the speed of the rear substrate to the process speed vp.

Owner:SINGULUS TECHNOLGIES AG

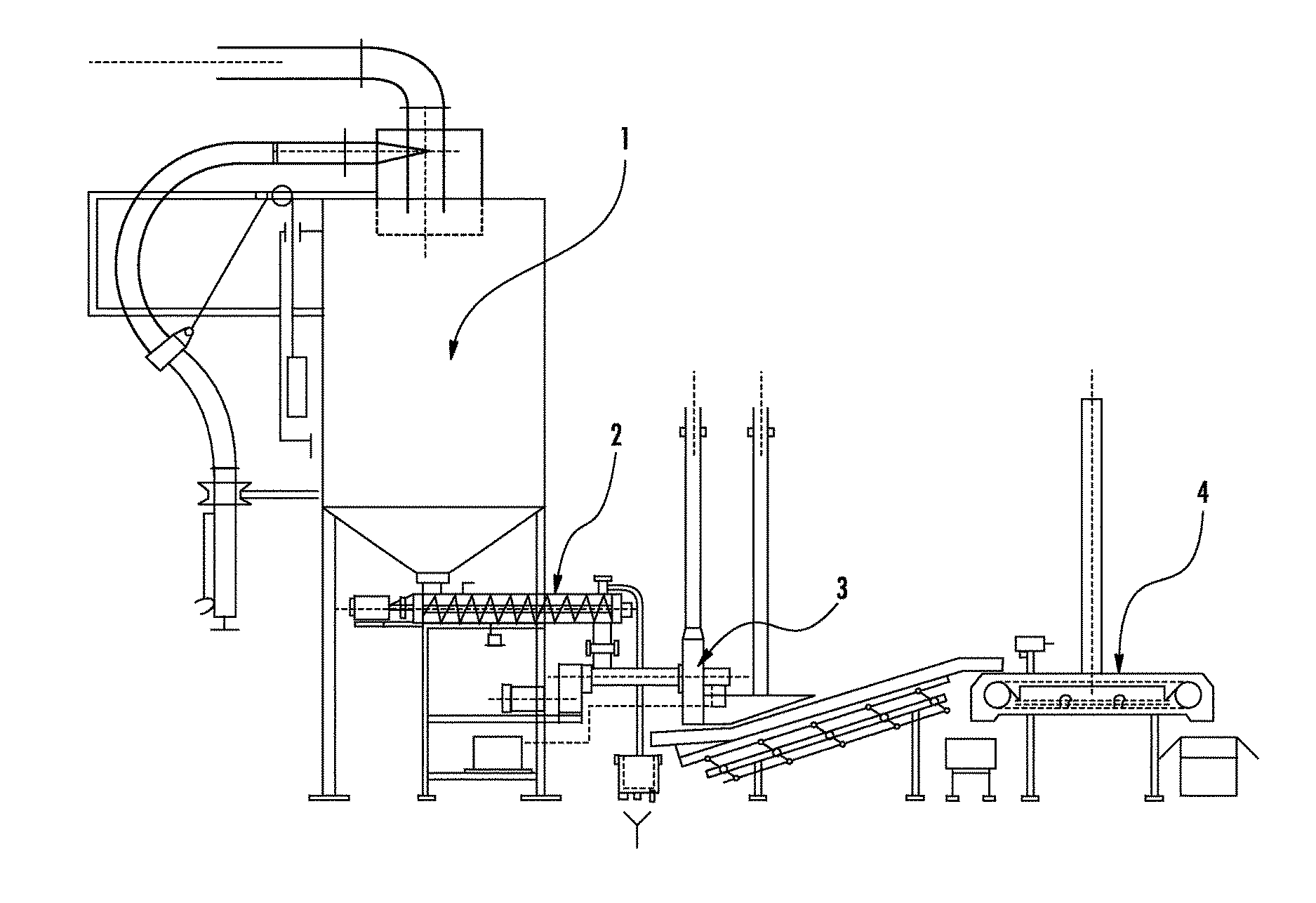

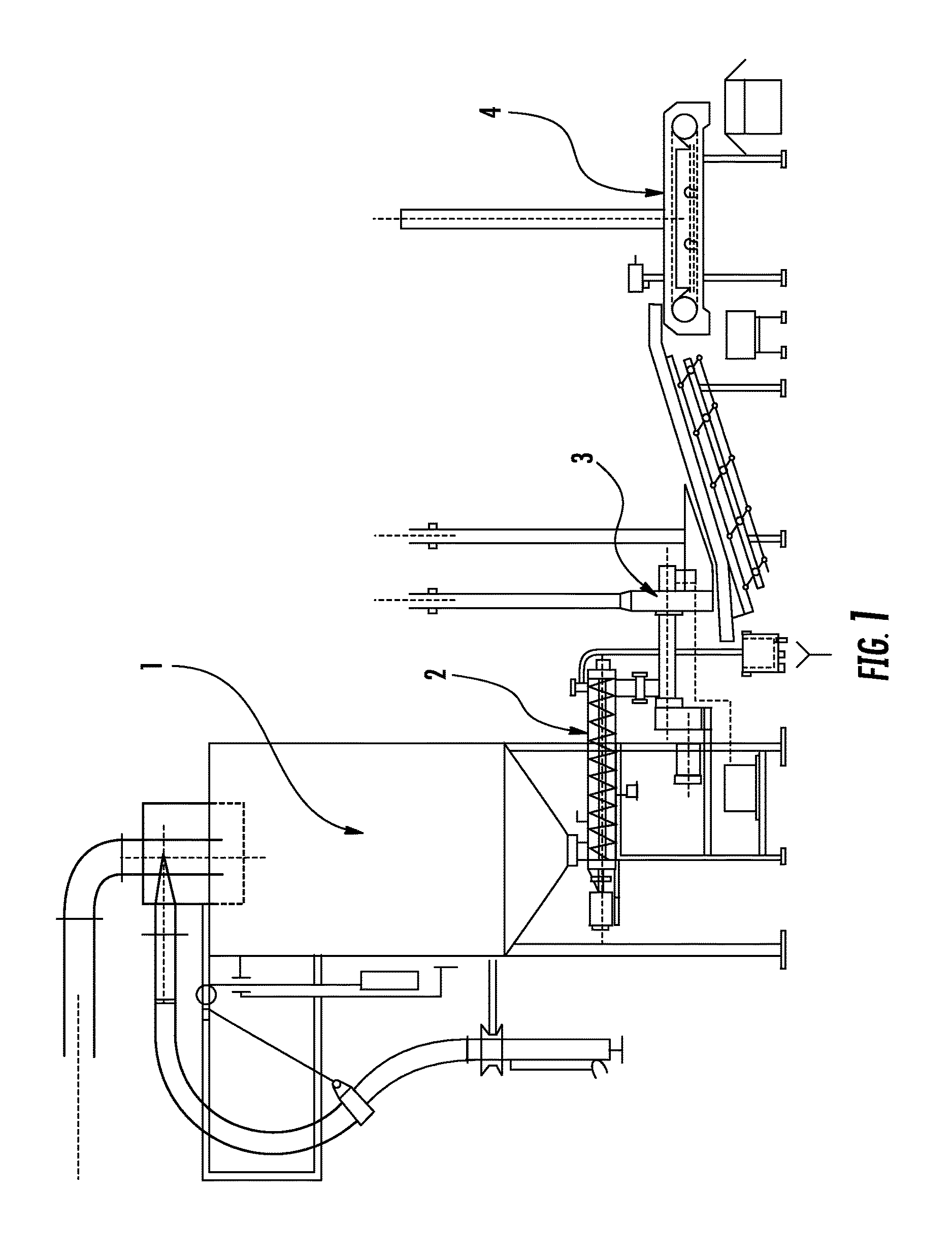

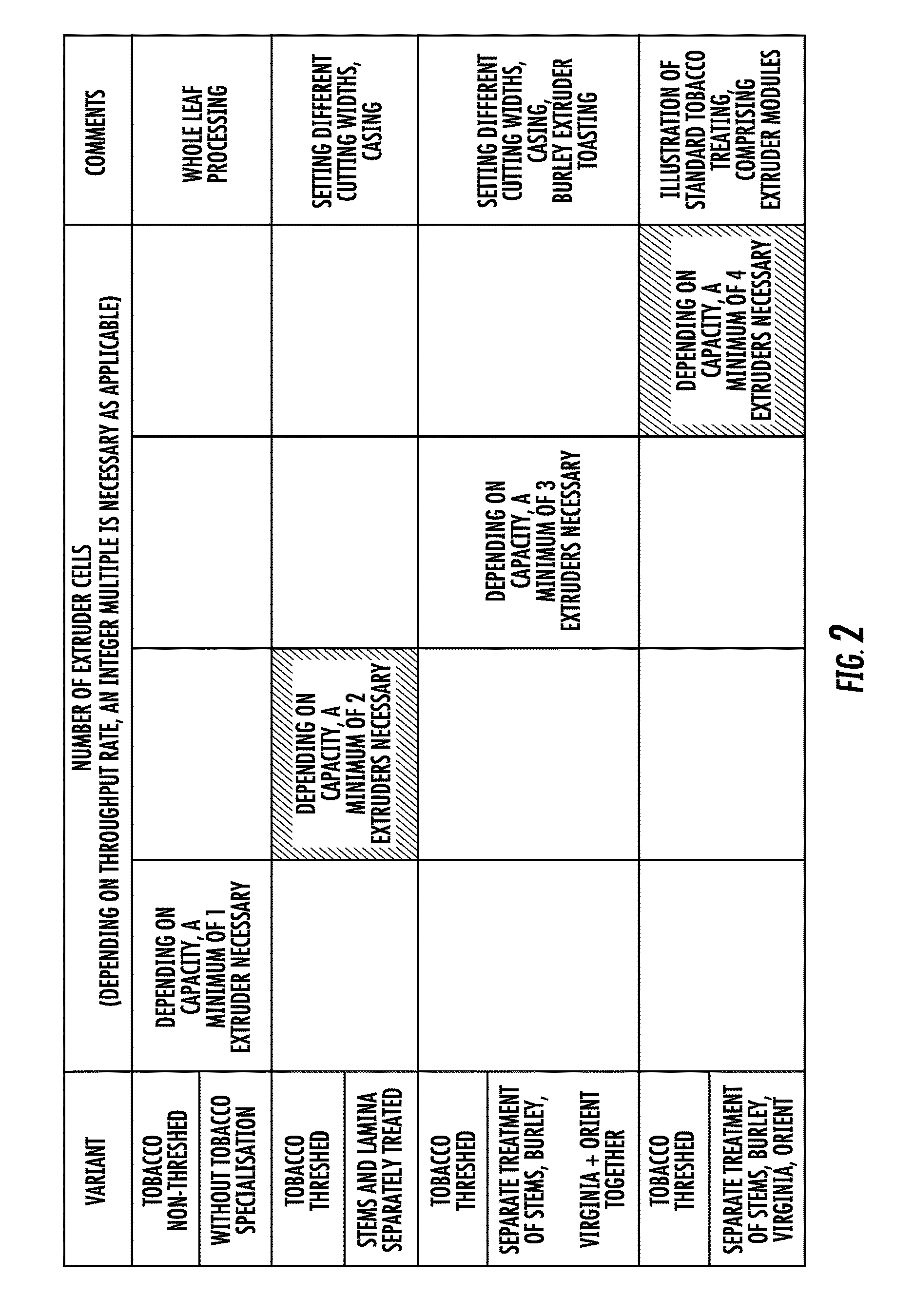

Modular Tobacco Preparation Including Extrusion

ActiveUS20170035097A1Optimize tobacco preparationArray-easier to manipulateTobacco preparationTobacco treatmentCigarette MakersEngineering

A tobacco preparation method, where a tobacco material is prepared through at least one extrusion process including compressing the material with an increase in pressure and temperature and mechanically processing and abruptly flash drying the material at an extruder outlet, wherein the tobacco material includes a tobacco lamina material, where a tobacco preparation device includes a dosing conveyor and an extruder which compresses a tobacco material with an increase in pressure and temperature and mechanically process and abruptly flash dries the material at the extruder outlet, wherein the components are designated as a unit which can be modularly delimited for processing a tobacco material including a tobacco lamina material, where an arrangement of several tobacco preparation devices and a smoking article or cigarette manufacturing device includes such a device or such a device arrangement which is connected upstream of a cigarette maker or a secondary unit as a tobacco preparation module.

Owner:BRITISH AMERICAN TABACCO (GERMANY) GMBH

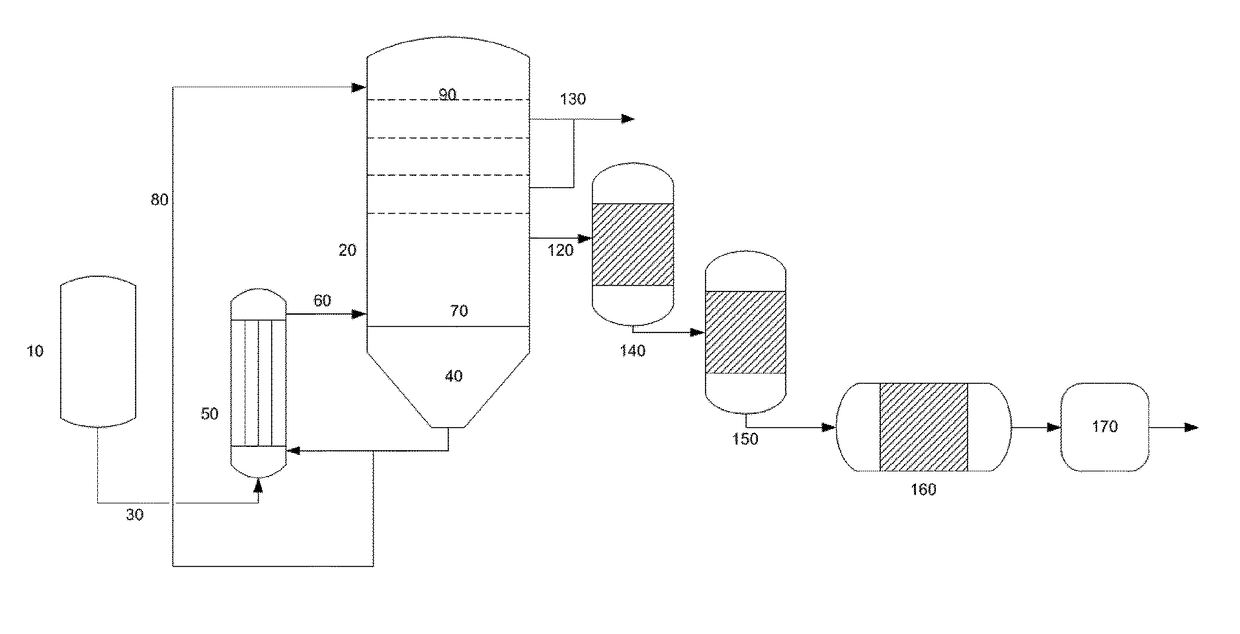

Continuous process for making polybutylene terephthalate using purified terephthalic acid and 1,4-butane diol

ActiveUS20170369638A1Reduce stressImprove balanceChemical/physical/physico-chemical stationary reactors1,4-ButanediolPolytetramethylene terephthalate

Disclosed is a continuous process and device for making polybutylene terephthalate (PBT) resin, particularly high molecular weight PBT resin. Also disclosed are a device for conducting the process, and a monitoring process for determining the carboxylic acid end group concentration of the resulting PBT.

Owner:SABIC GLOBAL TECH BV

Board for stringed instrument, method of manufacturing board for stringed instrument, and stringed instrument

A board for a stringed instrument which forms a front plate or a back plate of a stringed instrument, includes: a veneer that includes a concave portion for partially reducing the thickness of the veneer, in which the veneer is curved to be convex toward one surface side. In this board for a stringed instrument, fiber of the veneer may extend along the curved shape of the veneer.

Owner:YAMAHA CORP

Method and device for stringing substrates together in coating systems

ActiveUS20160325941A1Accurate detectionDamage is causedConveyorsSemiconductor/solid-state device manufacturingTransport systemCoating system

A method and a device for stringing together objects in transport systems, preferably in coating systems, for adjusting the distance between two objects, preferably substrates or substrate holders, being arranged one behind the other, wherein the front object moves at a process speed vp in the transport system and the rear object is at an undefined distance from the front object. The method comprises the following steps: (a) accelerating the rear substrate to an initial speed vx>vp; (b) detecting an increase in the driving torque when the rear substrate moves against the front substrate; (c) delaying the rear substrate by a predetermined value in order to establish a predetermined distance ap from the front substrate; and (d) adjusting the speed of the rear substrate to the process speed vp.

Owner:SINGULUS TECHNOLGIES AG

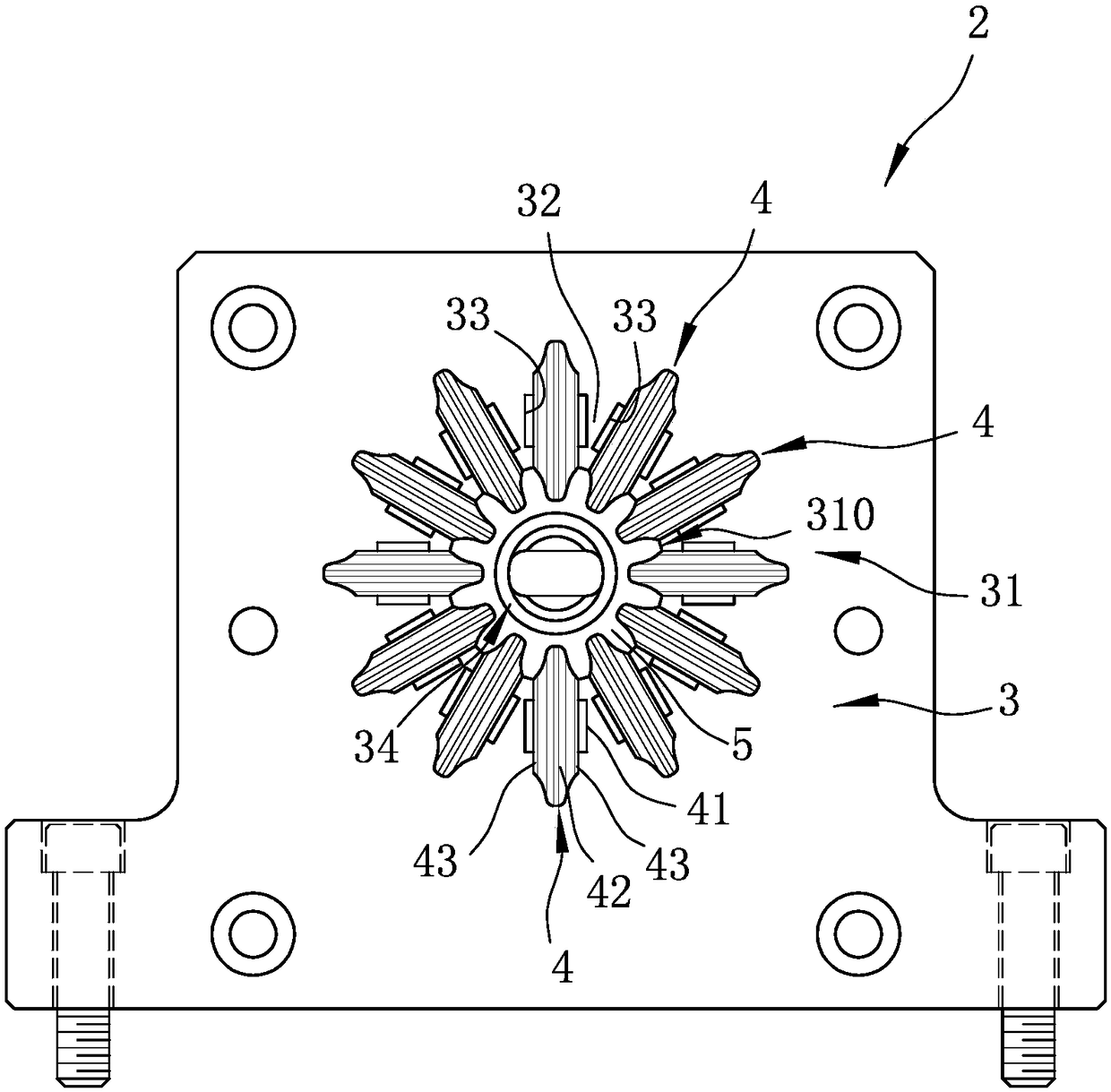

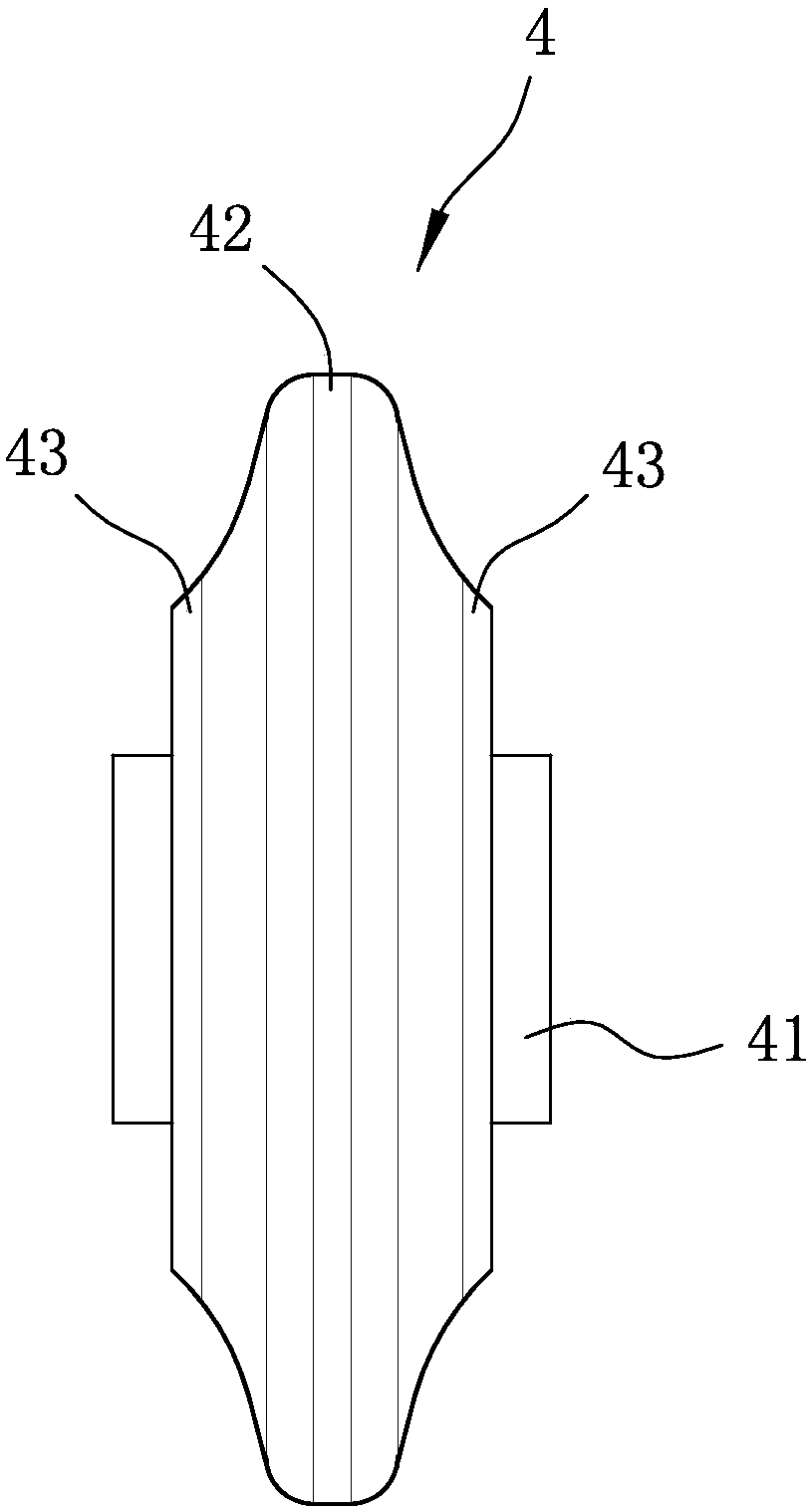

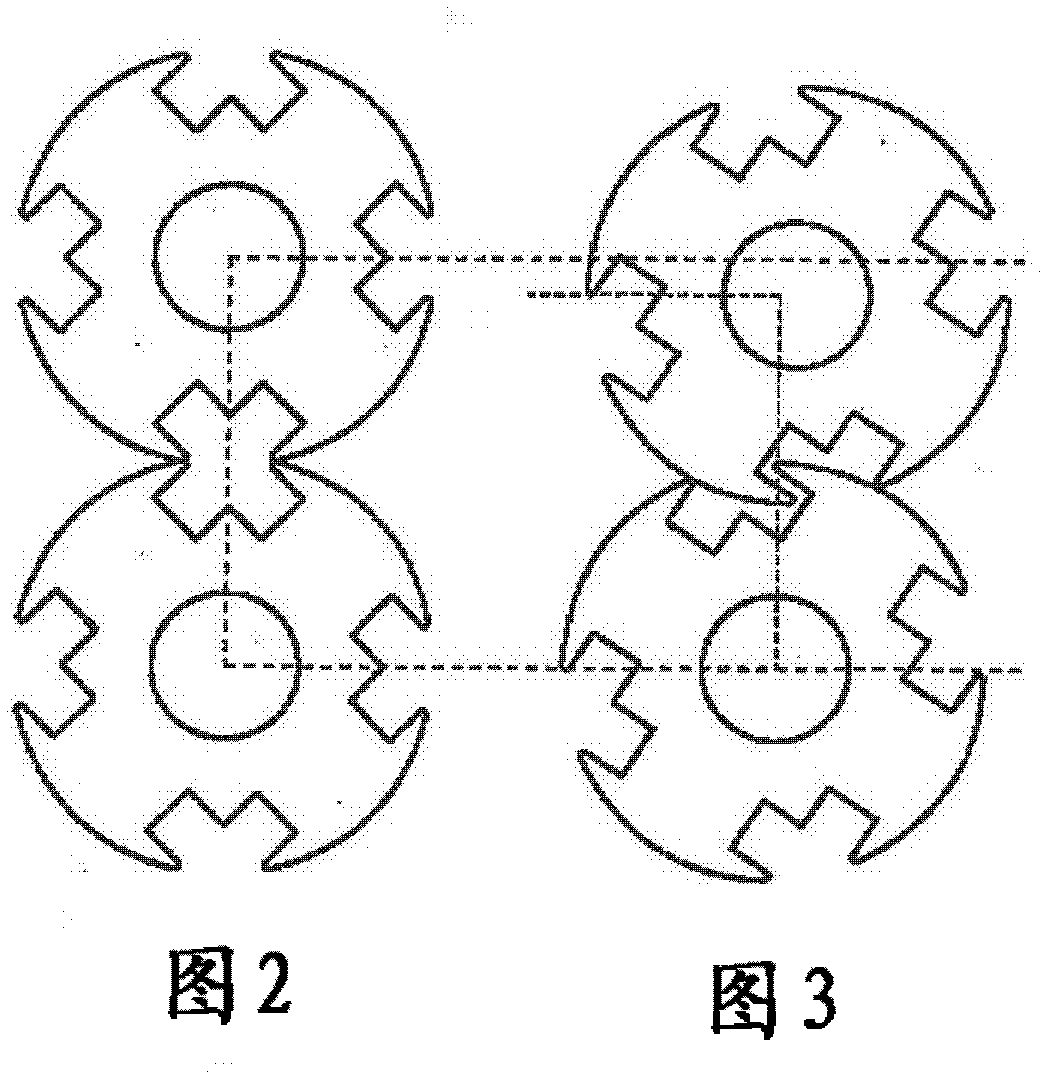

Gear forming device and gear manufacturing method

InactiveCN108246941AHigh material yieldIncrease production rateGear wheelsGear manufacturingSpur gear

Provided are a gear forming device and a gear manufacturing method. The gear forming device comprises a base and a plurality of idler wheels. The base comprises a body part defining a space, and a plurality of spacing parts which are arranged in the space at intervals and at equal angles. The space is divided into a plurality of containing grooves and a through groove communicating with the containing grooves through the spacing parts. The idler wheels are arranged in the containing grooves of the base in a pivoted mode correspondingly, and part of the idler wheels extend into the through groove, and thus a mold hole corresponding to the tooth form feature of a gear is defined. A bar can be processed to form the tooth form feature after passing through the mold hole, and a plurality of spur gears are obtained after post-processing is conducted.

Owner:METAL INDS RES & DEV CENT

Fabrication of a scintillator material of elpasolite type

ActiveUS20180246230A1High material yieldImprove yieldPolycrystalline material growthBy pulling from meltLithiumMetallurgy

The present disclosure relates to a process for fabricating a crystalline scintillator material with a structure of elpasolite type of theoretical composition A2BC(1-y)MyX(6-y) wherein:A is chosen from among Cs, Rb, K, Na,B is chosen from among Li, K, Na,C is chosen from among the rare earths, Al, Ga,M is chosen from among the alkaline earths,X is chosen from among F, Cl, Br, I,y representing the atomic fraction of substitution of C by M and being in the range extending from 0 to 0.05, comprising its crystallization by cooling from a melt bath comprising r moles of A and s moles of B, the melt bath in contact with the material containing A and B in such a way that 2s / r is above 1. The process shows an improved fabrication yield. Moreover, the crystals obtained can have compositions closer to stoichiometry and have improved scintillation properties.

Owner:LUXIUM SOLUTIONS LLC

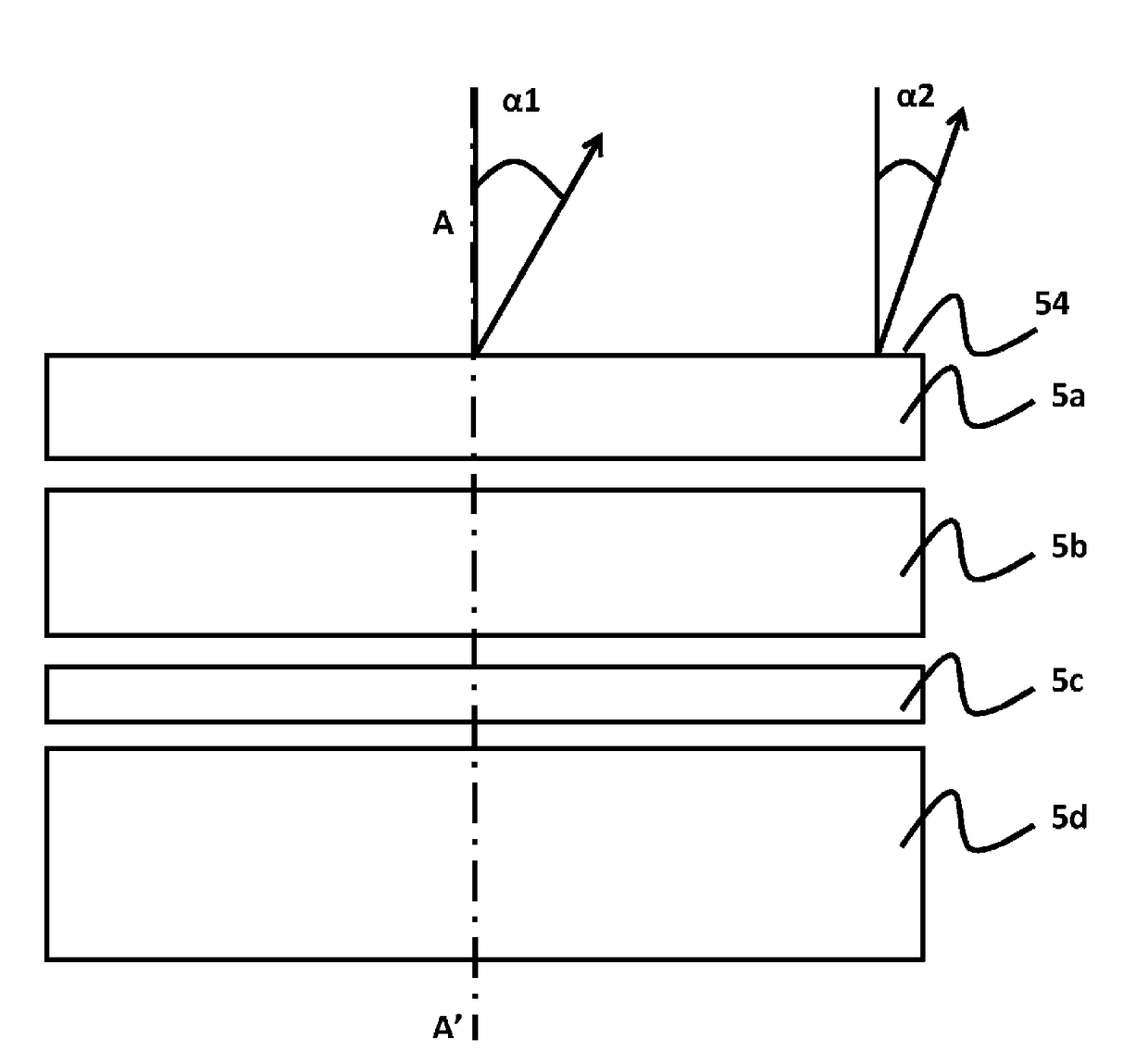

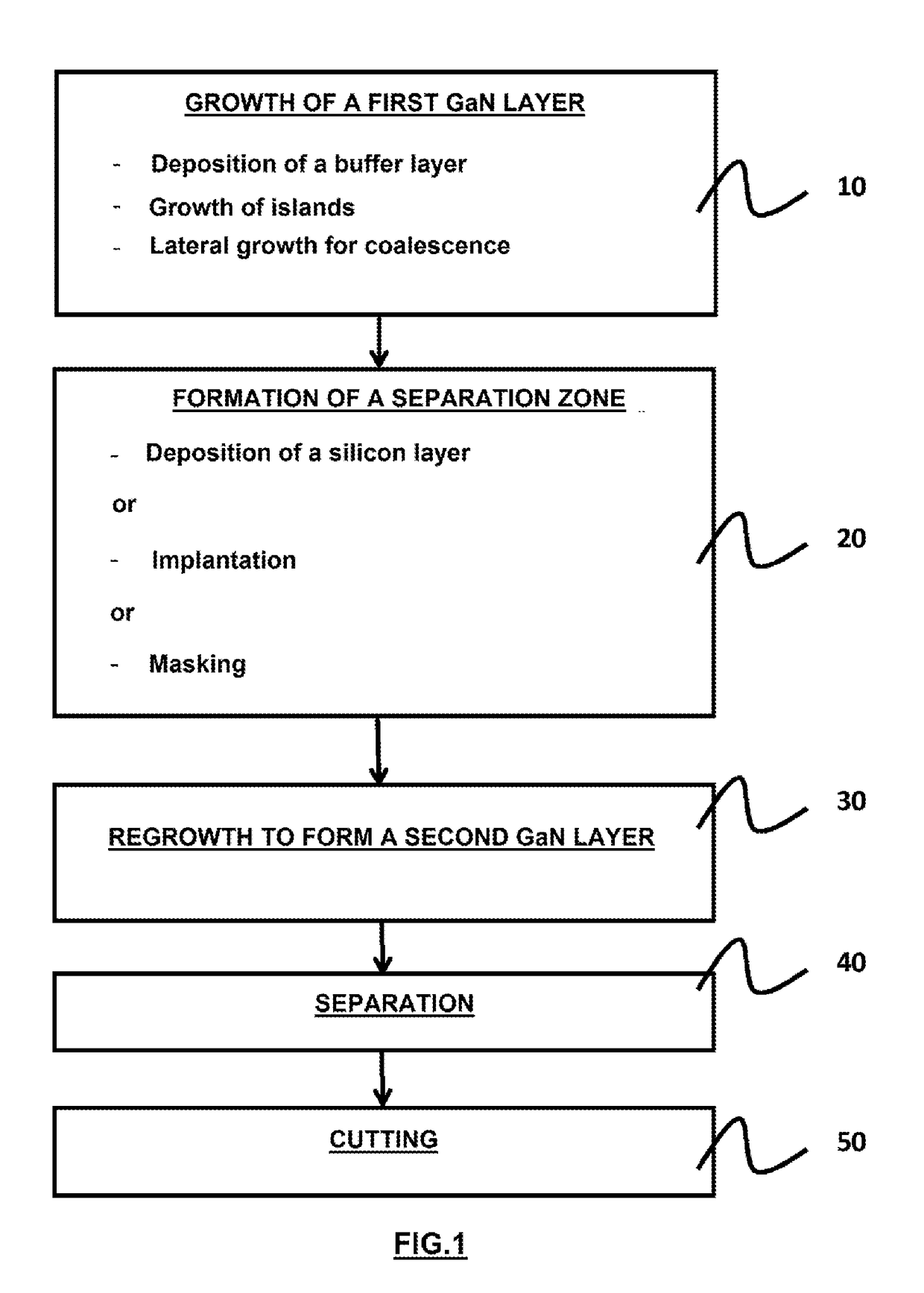

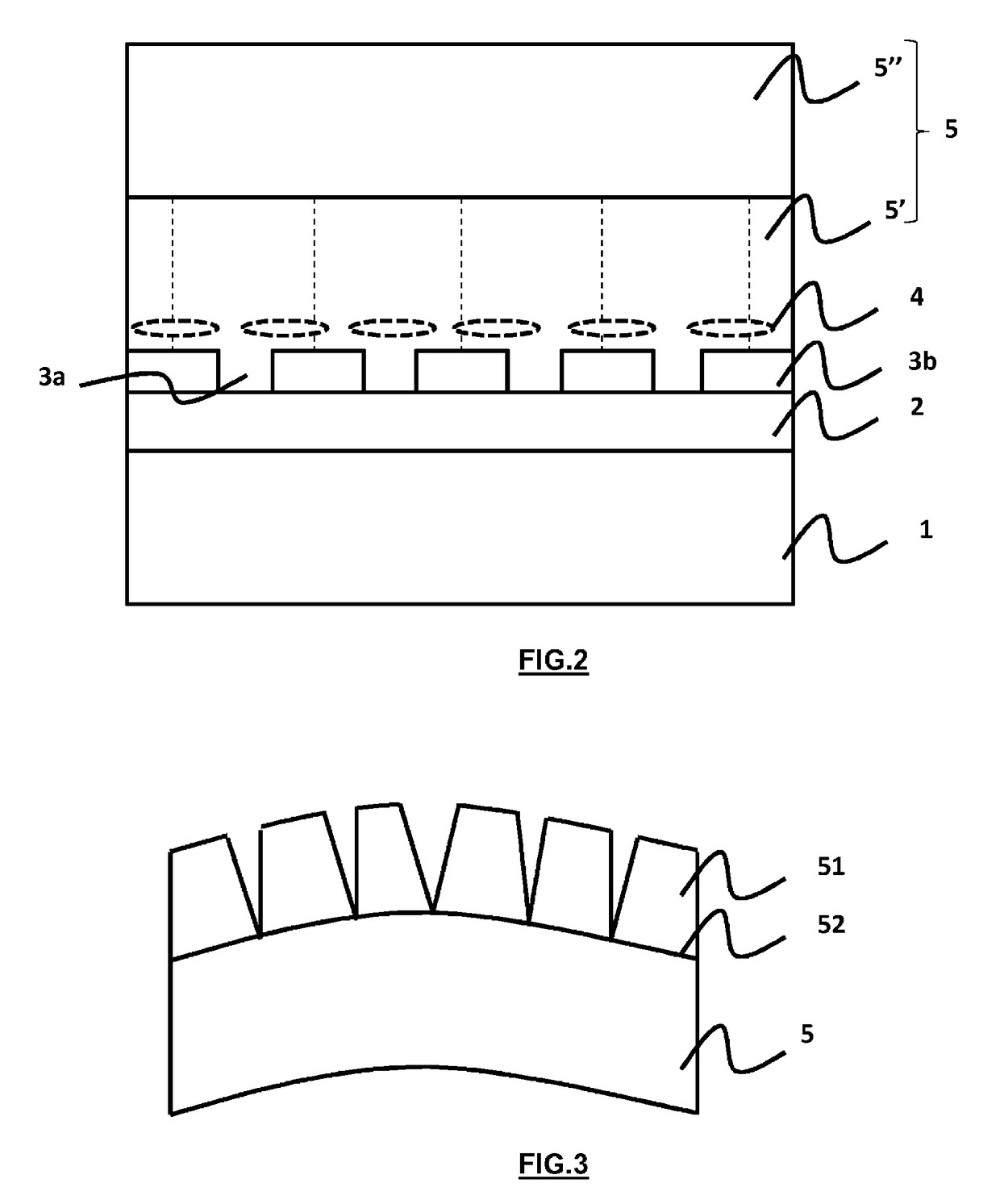

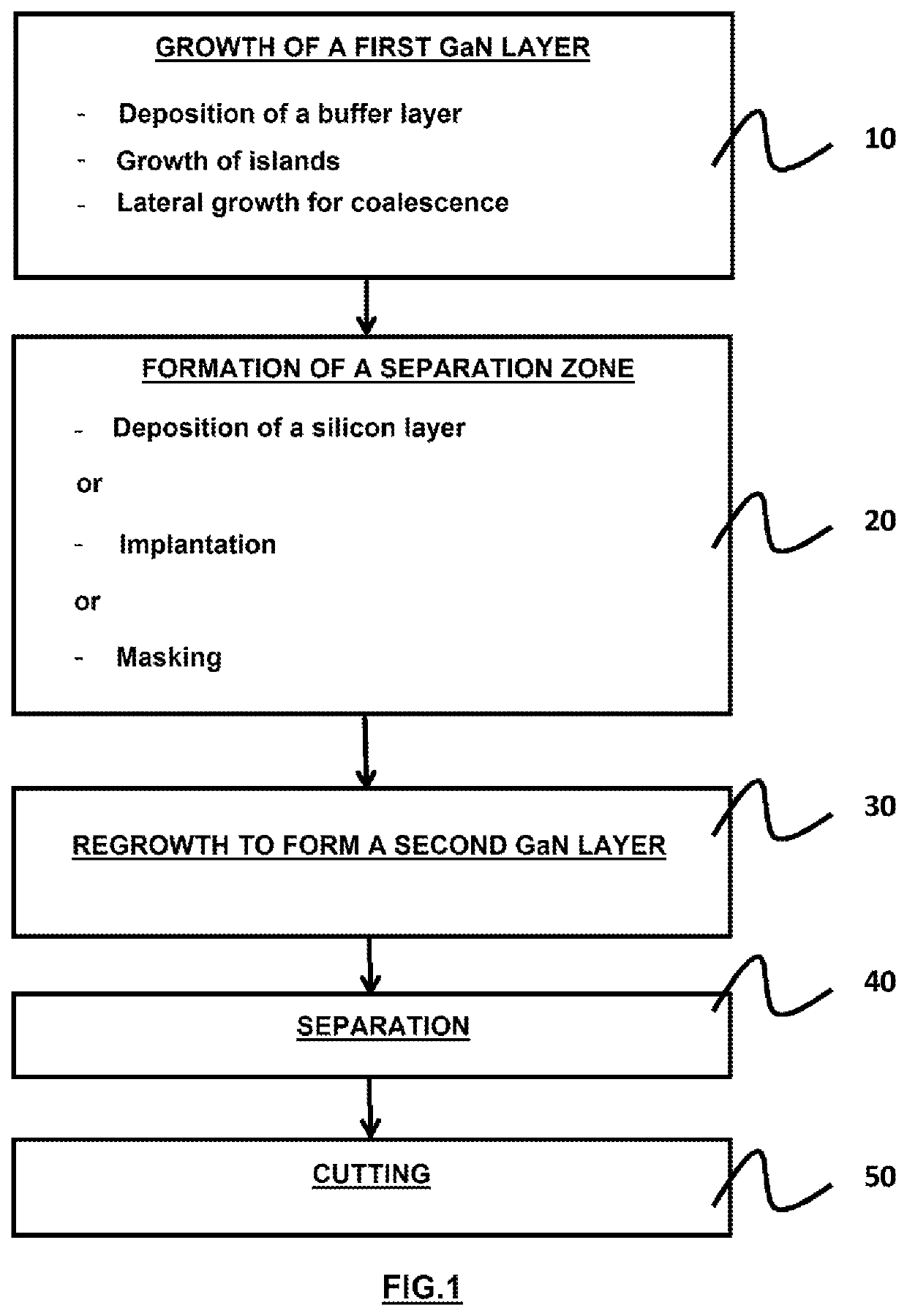

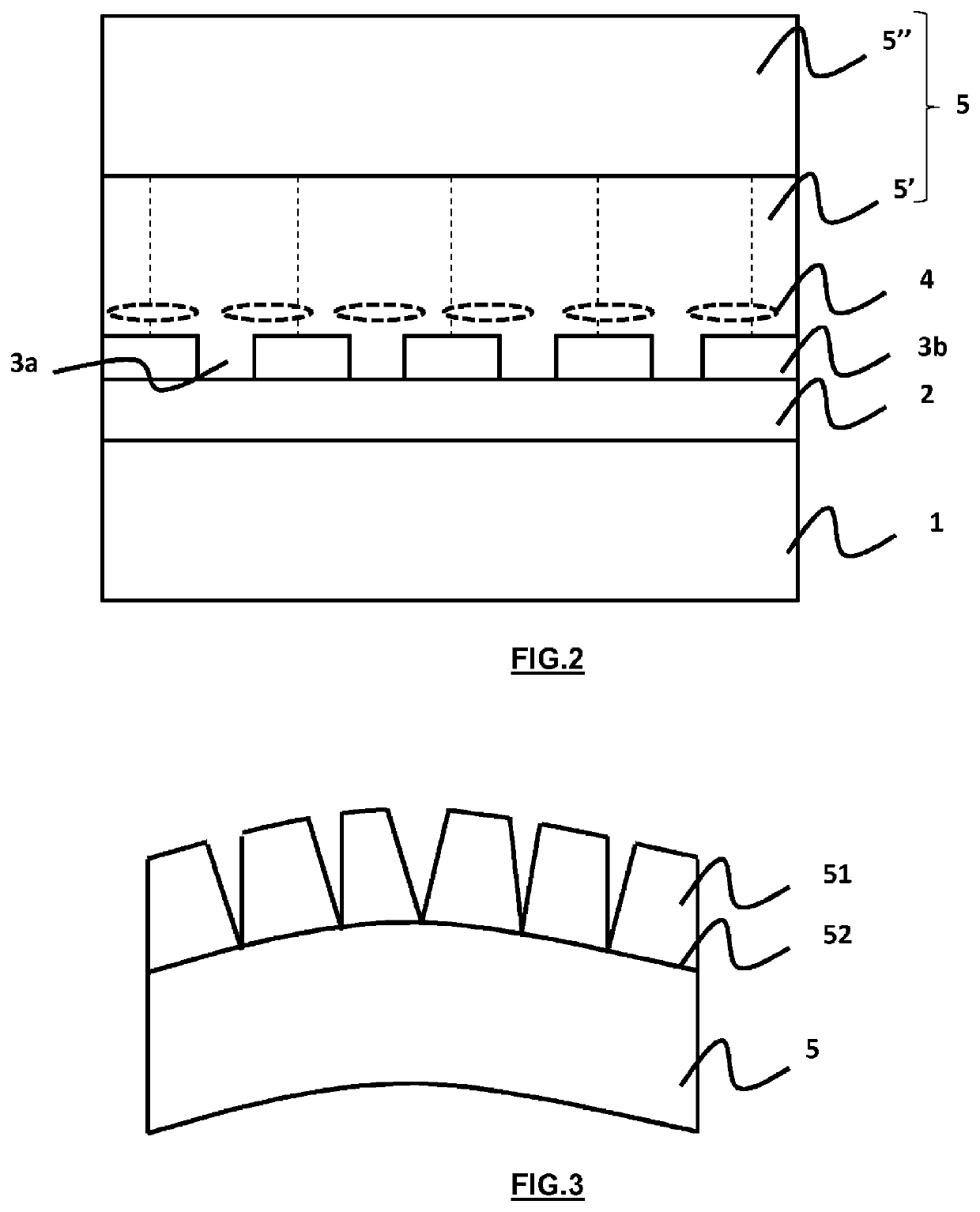

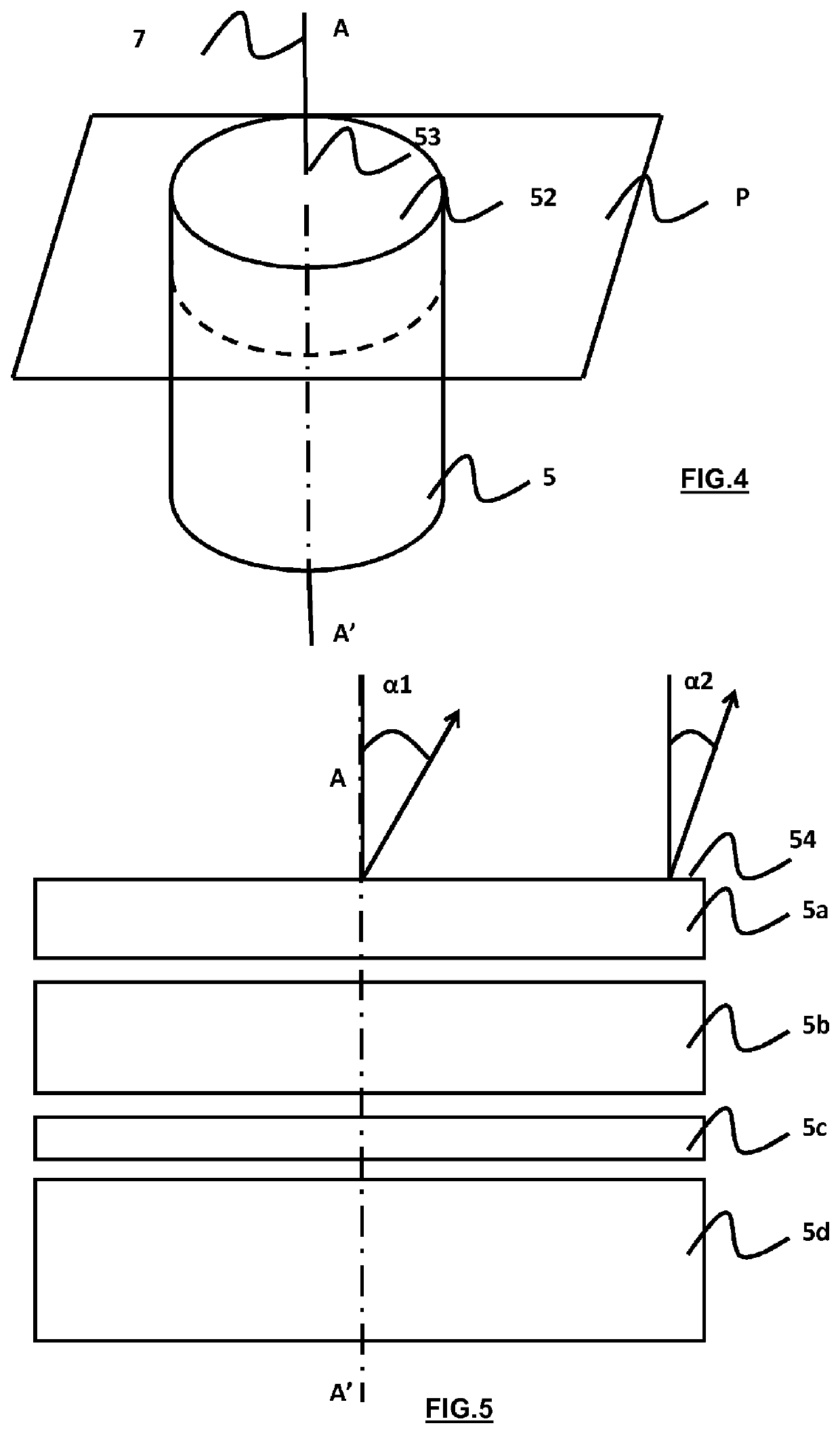

Method for the production of wafers of nitride of element 13, having a non-zero truncation angle

ActiveUS20180155852A1Easy to separateHigh material yieldPolycrystalline material growthAfter-treatment detailsEngineeringCrystal growth

The invention relates to a method for production of wafers of nitrides of element (13) (5a, 5b, 5c, 5d) from a self-supported crystal of nitride of element (13), extending longitudinally along a main axis orthogonal to a growth face of the crystal and passing through the centre of said growth face, the crystal (10) having a truncation angle with a non-zero value, remarkable in that the method comprises a phase of cutting the self-supported crystal along the transverse cutting planes of the crystal in order to obtain wafers of nitride of element (13), each wafer including a front face having a non-zero truncation angle in the vicinity of the centre of the front face.

Owner:IV WORKS

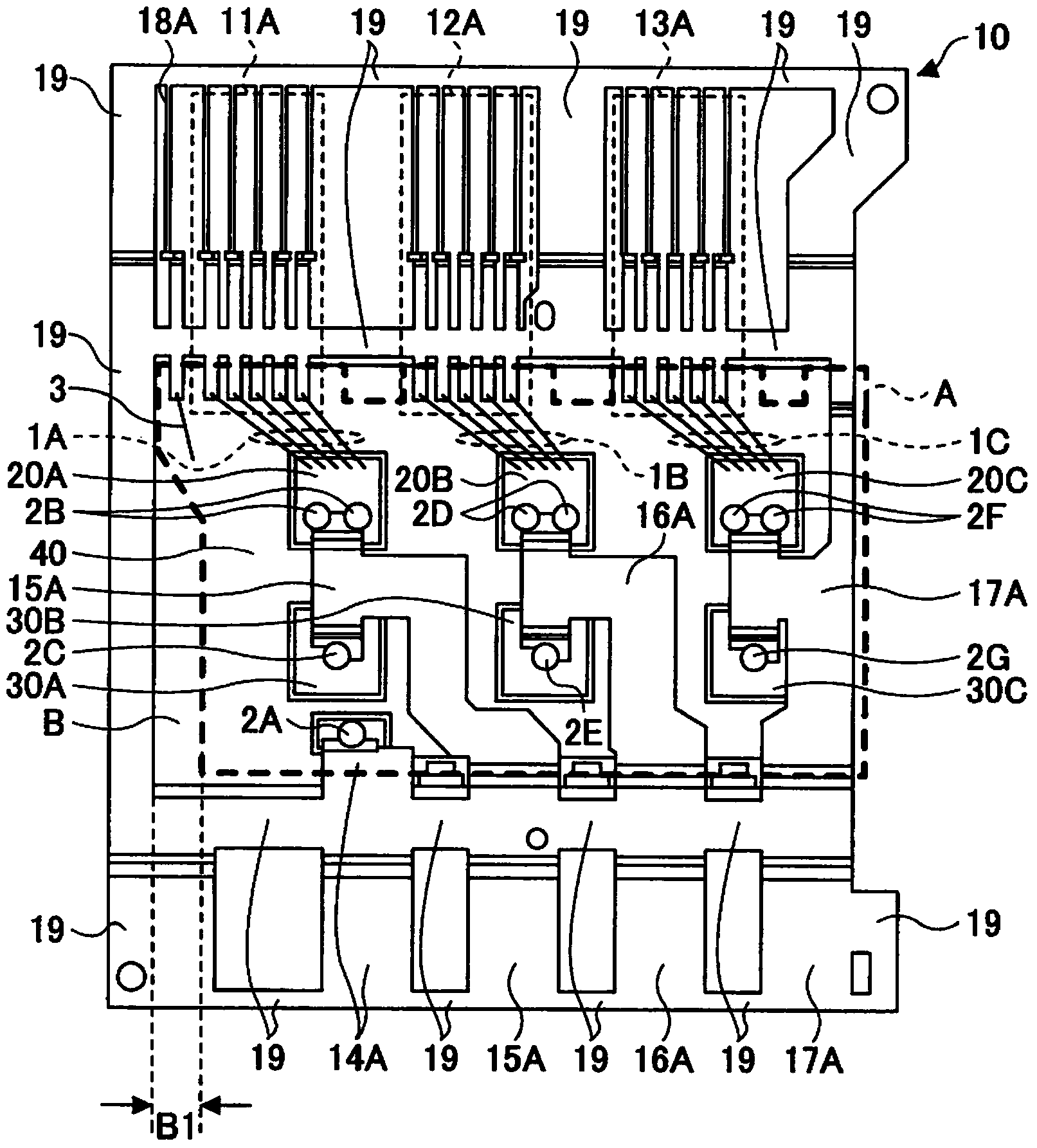

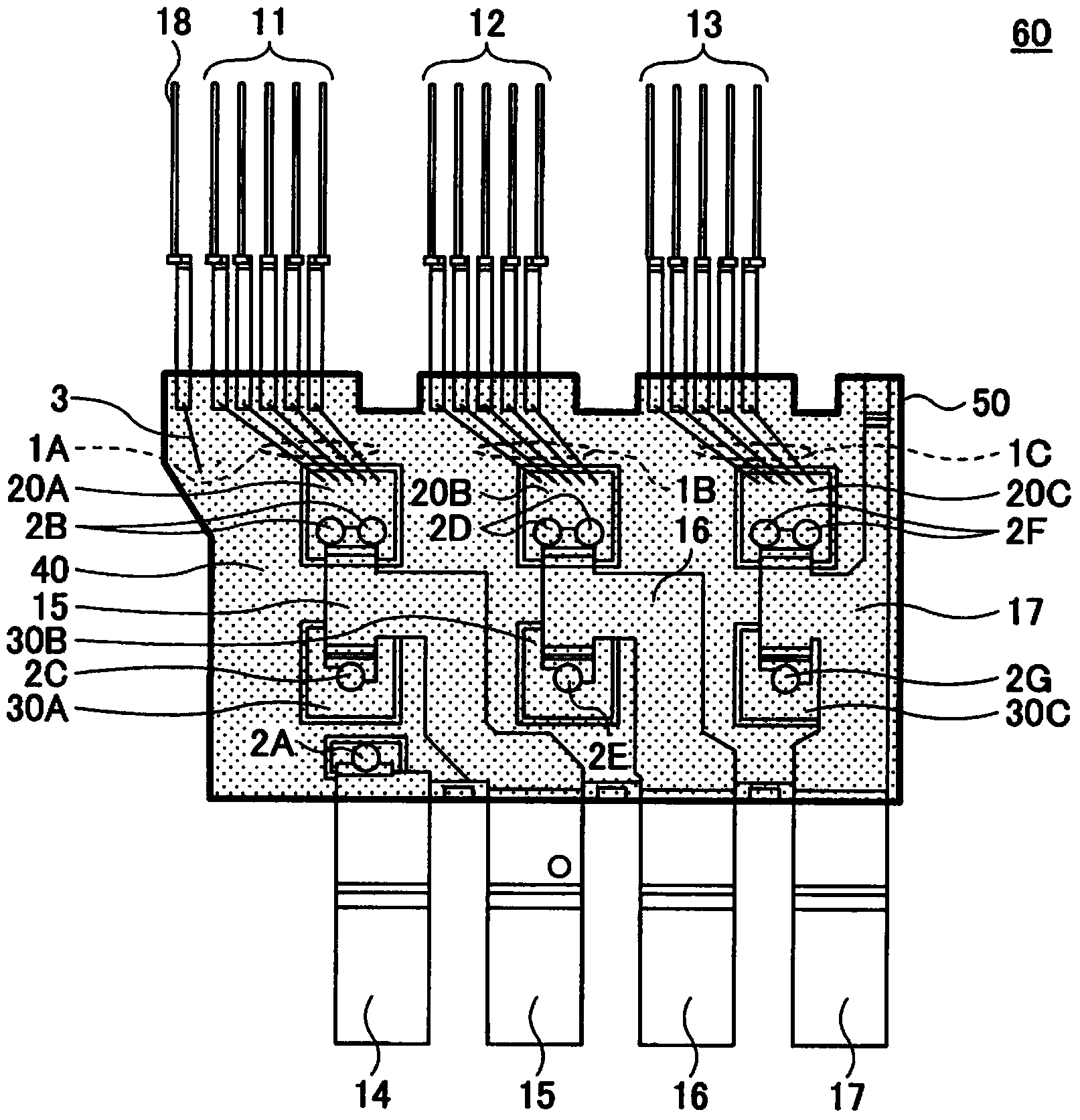

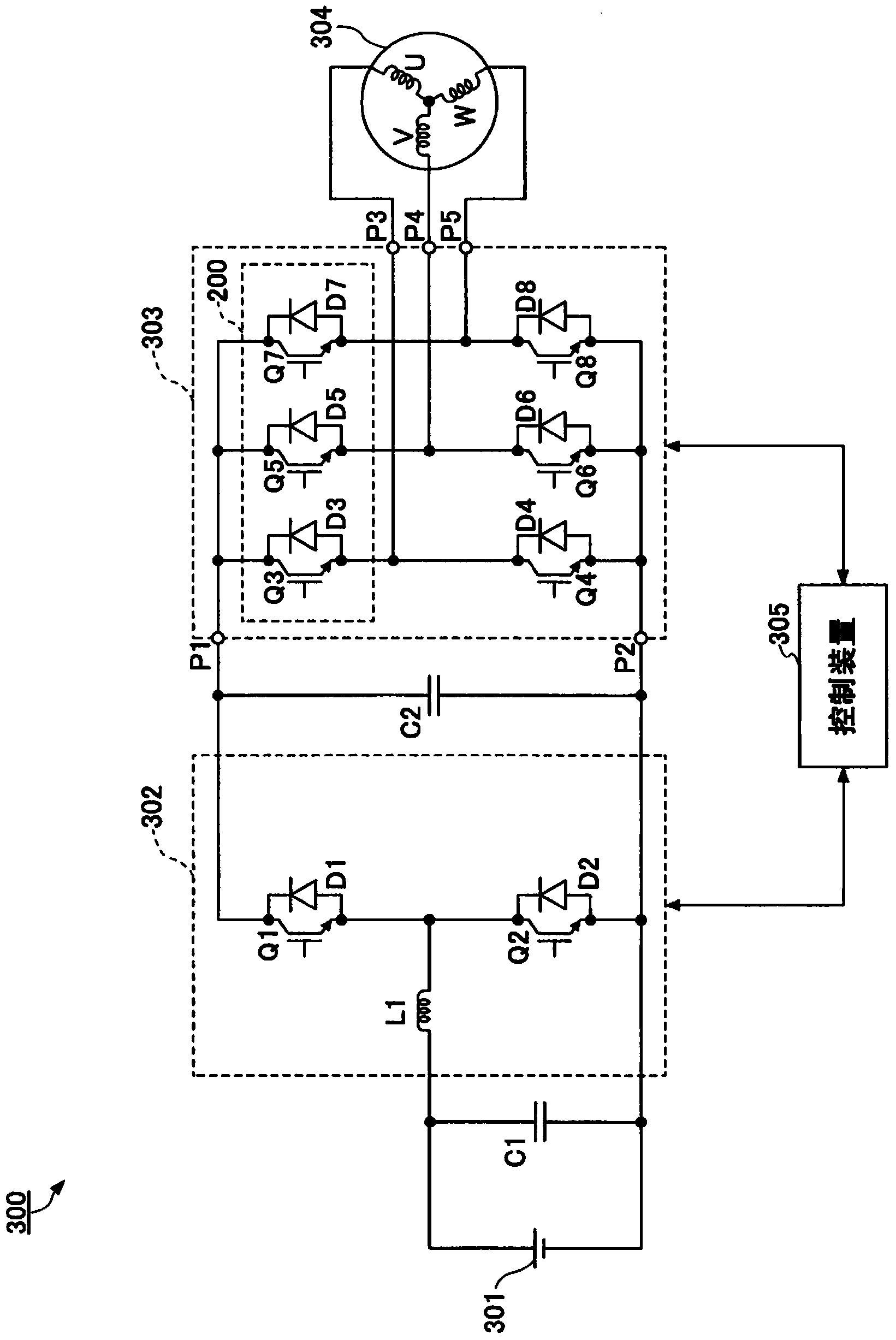

Lead frame and power module

InactiveCN103620768AHigh material yieldHigh yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringLead frame

The present invention addresses the problem of providing a lead frame and a power module with a high material yield. The lead frame includes: multiple first leads that extend on one side of a region where a semiconductor element is provided in a plan view; multiple second leads that extend on the other side opposite to the one side of the region where the semiconductor element is provided in the plan view; a third lead that is provided on the outer side of the first lead positioned at one end of the multiple first leads in the plan view; and a wiring section that is connected to the third lead, constitutes a portion of a guide frame for the first leads, second leads, and third lead, and is used as wiring to be connected to the third lead after portions of the guide frame excluding the above-mentioned portion are removed.

Owner:TOYOTA JIDOSHA KK

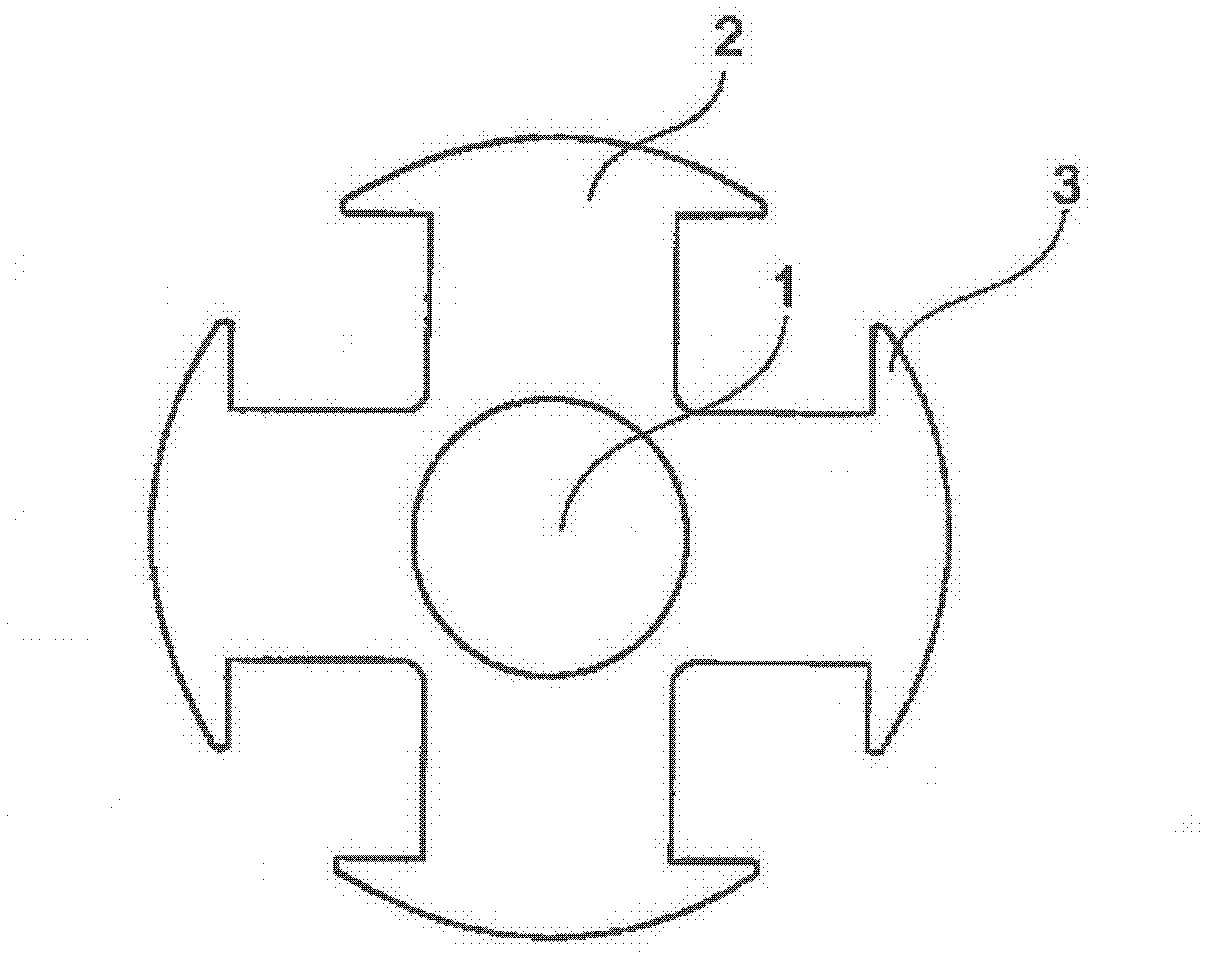

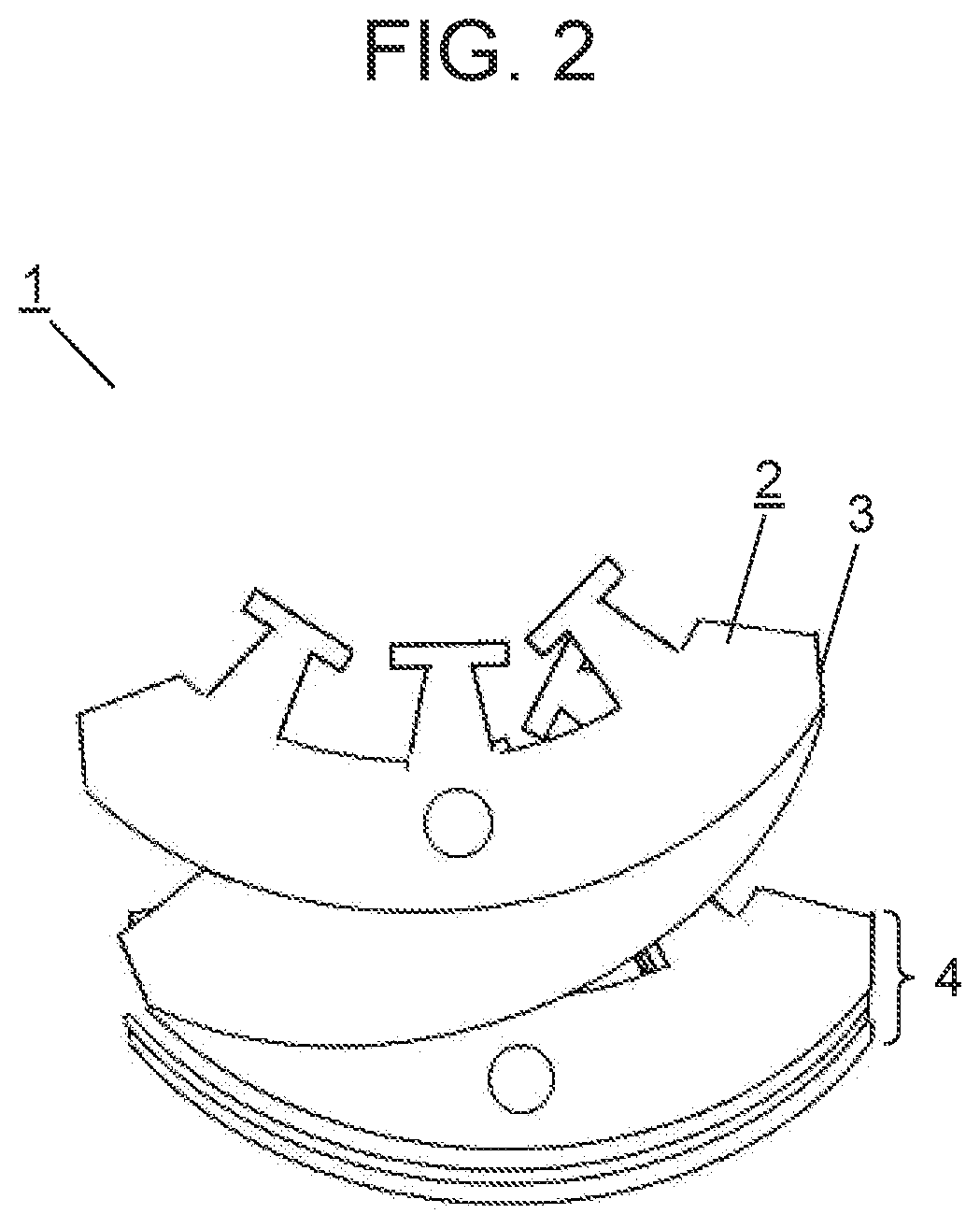

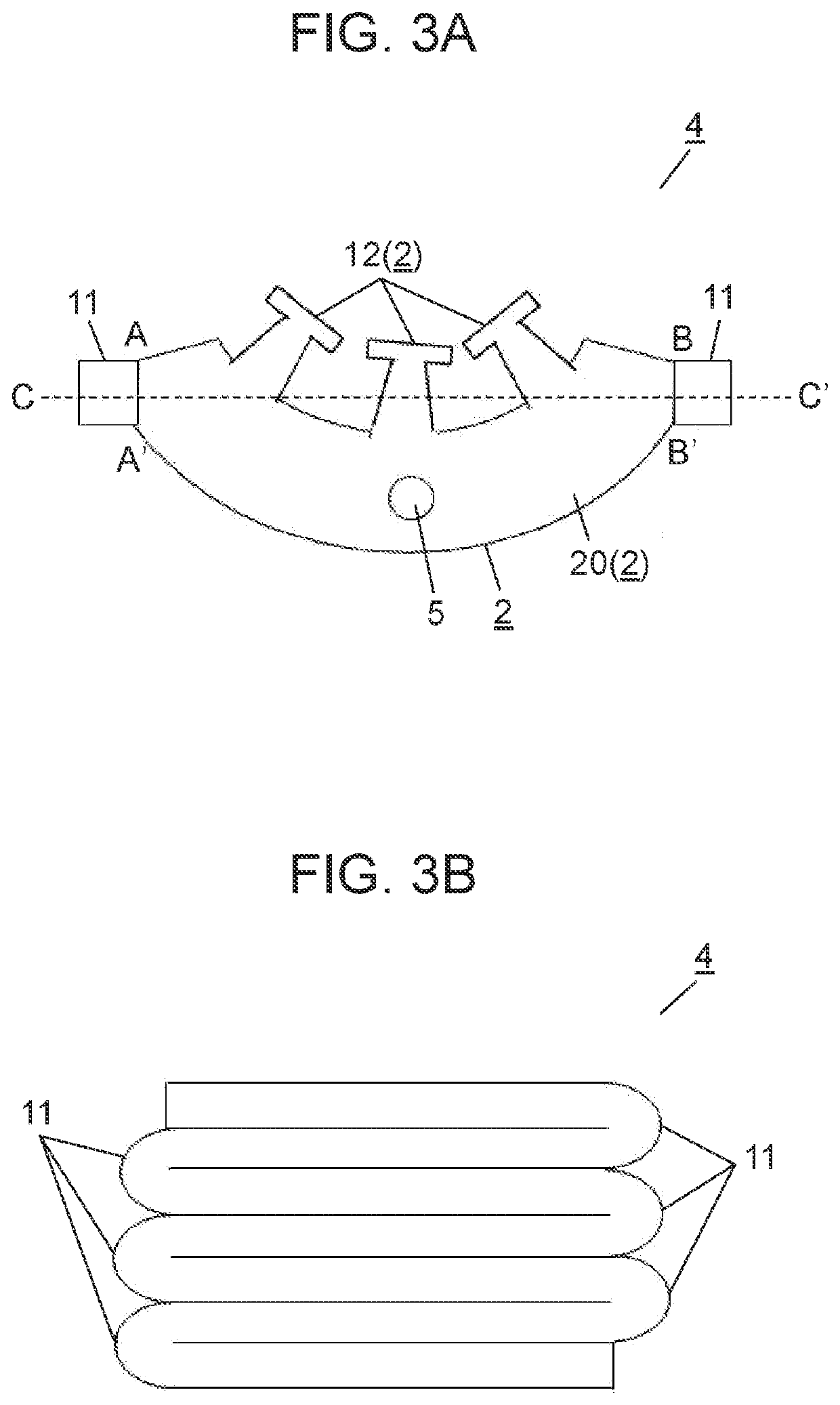

Rotor core

InactiveCN102969818AHigh material yieldReduce material consumptionMagnetic circuit rotating partsManufacturing dynamo-electric machinesRotary machineElectrical and Electronics engineering

The invention relates to a magnetic rotor core for an electric rotary machine, comprising a stack of magnetic laminations having poles provided with pole tips (3), said core being characterised in that the stack comprises laminations of which at least one of the poles has at least one at least partially truncated pole tip, preferably a single pole tip (3).

Owner:MOTEURS LEROY SOMER

Method of and apparatus for producing materials

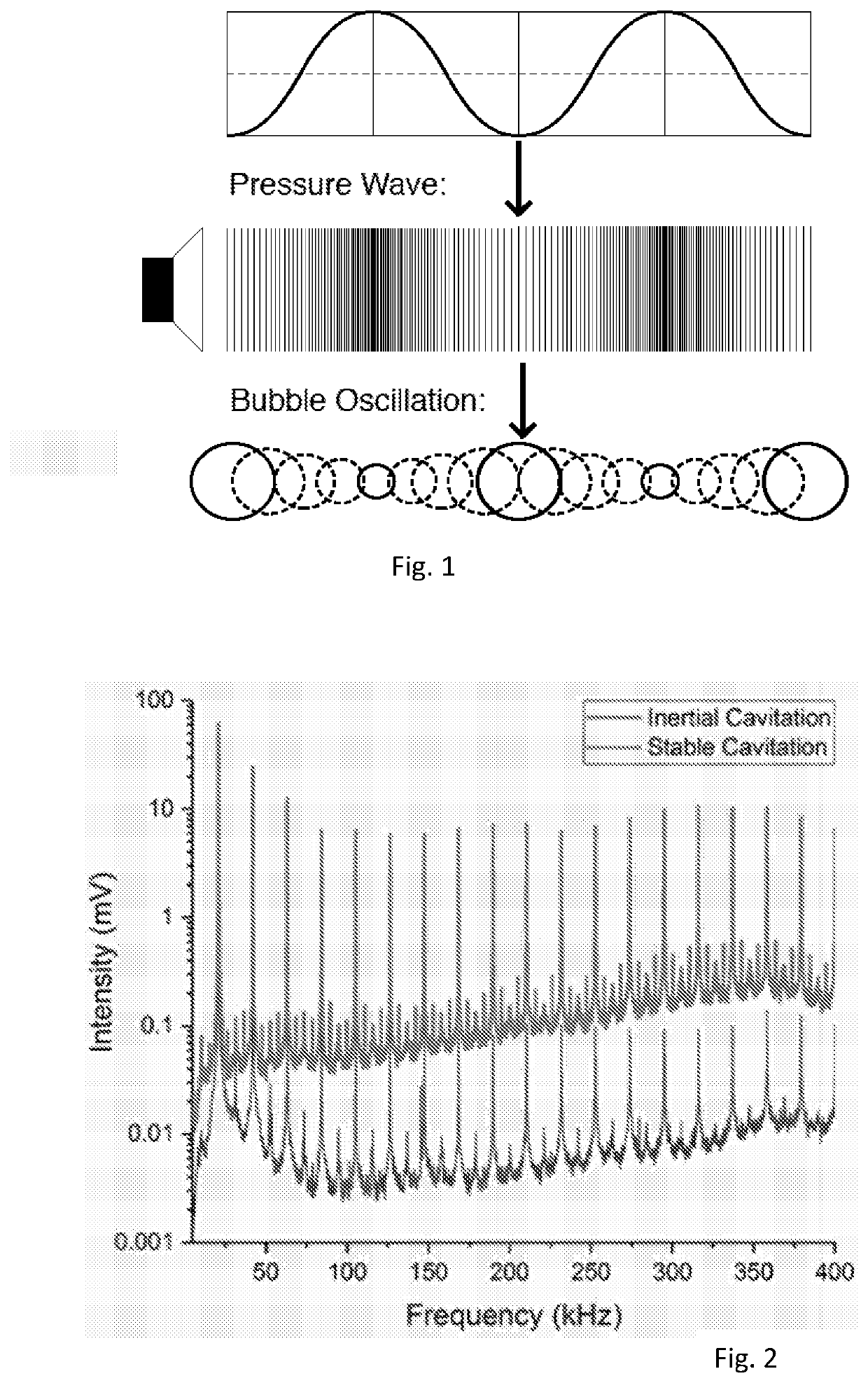

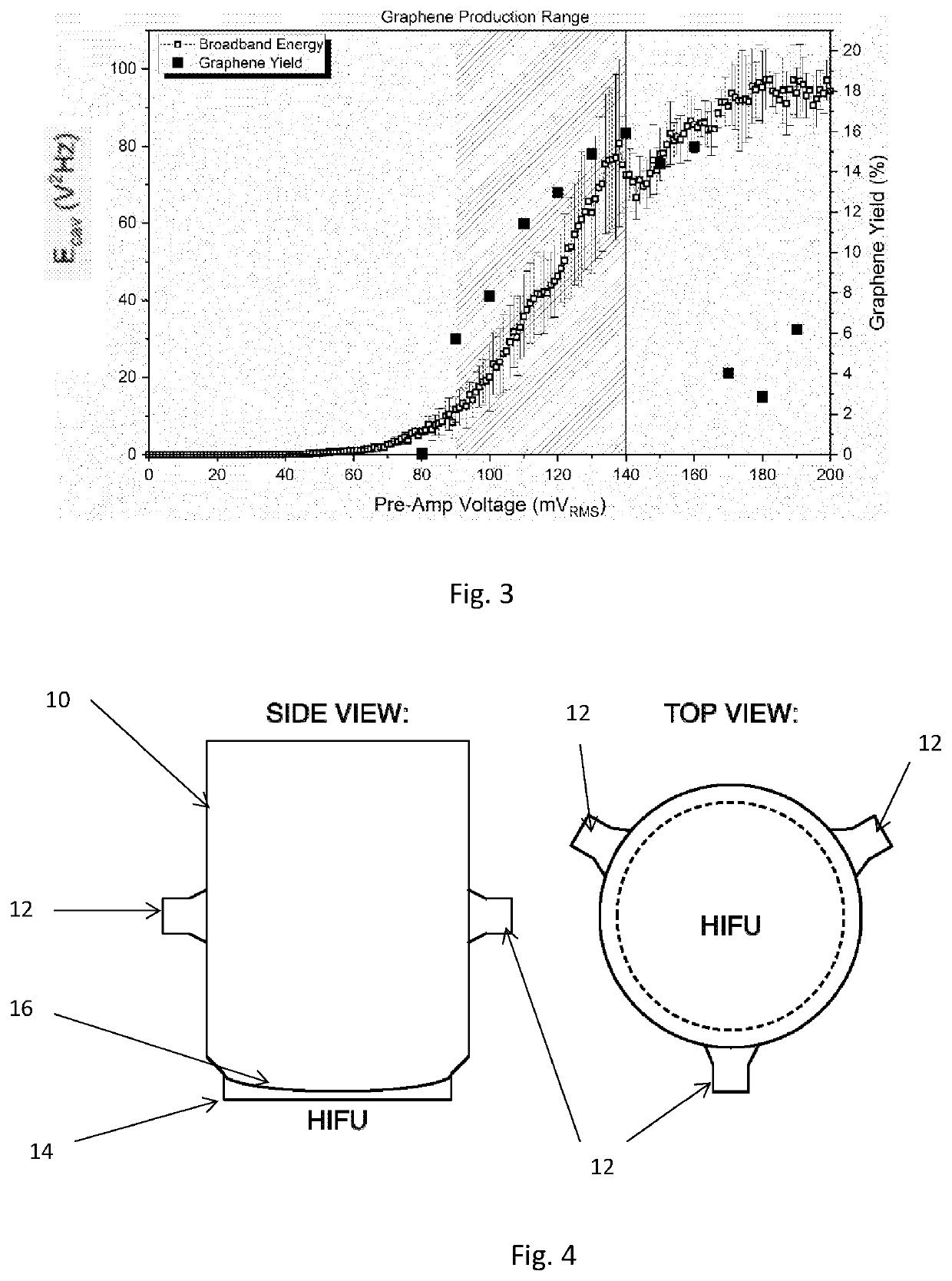

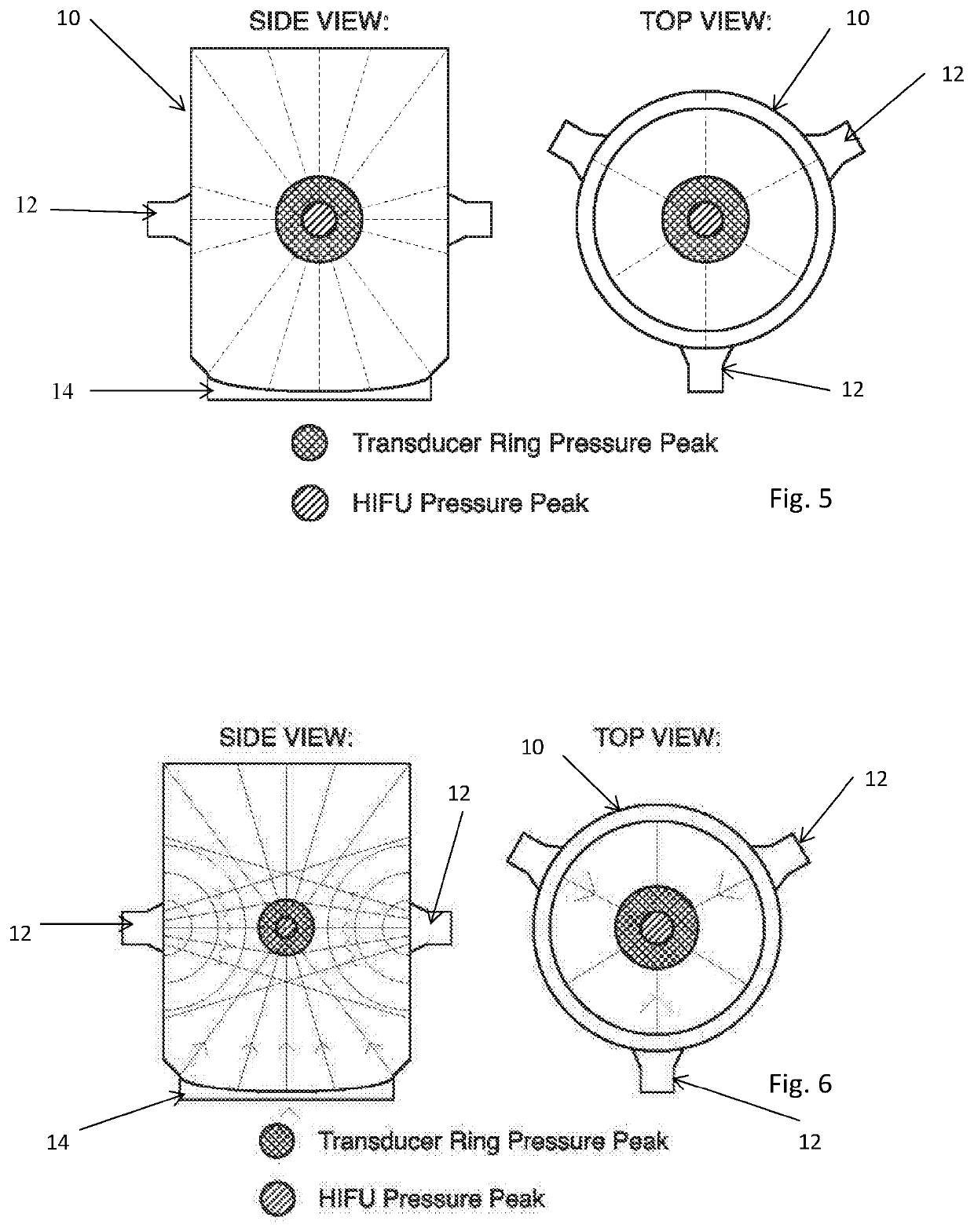

PendingUS20210346859A1High material yieldEfficient mechanismNanostructure manufactureGrapheneEngineeringHigh intensity

A method and apparatus produce materials by exfoliation from a bulk material, by disposing bulk material in suspension in a liquid in a chamber; applying superimposed ultrasound fields in the chamber, the superimposed ultrasound fields generating cavitation in the liquid at least at a zone of field superimposition; measuring cavitation in the chamber while applying the superimposed cavitation fields, at least at the zone of field superimposition; and adjusting at least one of the ultrasound fields on the basis of measured cavitation so as to control cavitation energy applied to the material and thereby to control exfoliation of the bulk material and the formation of materials therefrom. Inertial cavitation is controlled, resulting in significantly greater production yields compared to prior art systems and methods. A high intensity focused ultrasound transducer is provided to impart suspension energy to the liquid in the chamber for suspending bulk material in the zone of field superimposition.

Owner:NPL MANAGEMENT

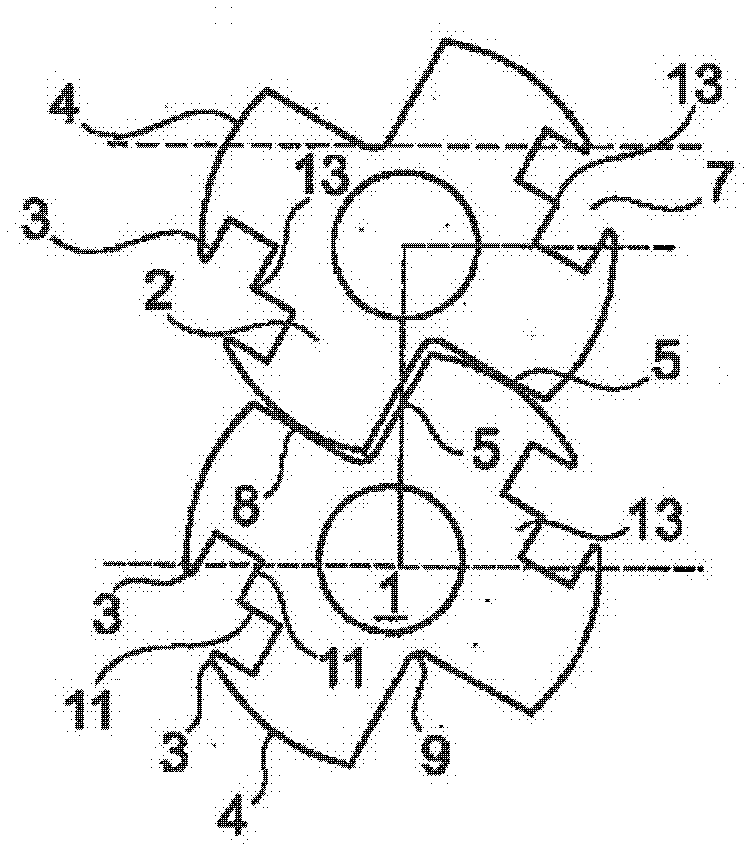

Manufacturing method of iron core, iron core, and stator

InactiveUS20210336516A1Improve material yieldImprove magnetic propertiesWindingsMagnetic circuit stationary partsMetallurgyEngineering

A manufacturing method of manufacturing an iron core includes connecting a plurality of iron core pieces each including a tooth portion and a yoke portion in a strip shape, connecting the iron core pieces adjacent to each other by a connection portion, and forming a continuous iron core piece provided line-symmetrically with reference to the connection portion. A laminated body is formed by bending and superimposing the iron core pieces adjacent to each other while the connection portion is used as a symmetry axis. A pressure is applied in a laminating direction of the laminated body to fix the laminated body, and a coil is provided in the tooth portion. In this manner, it is possible to realize a manufacturing method of an iron core, which have a high material yield, high productivity, and excellent magnetic properties by using a thin iron core piece.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method for the production of wafers of nitride of element 13, having a non-zero truncation angle

ActiveUS10604864B2High material yieldEasy to separatePolycrystalline material growthAfter-treatment detailsWaferingNitride

Owner:IV WORKS

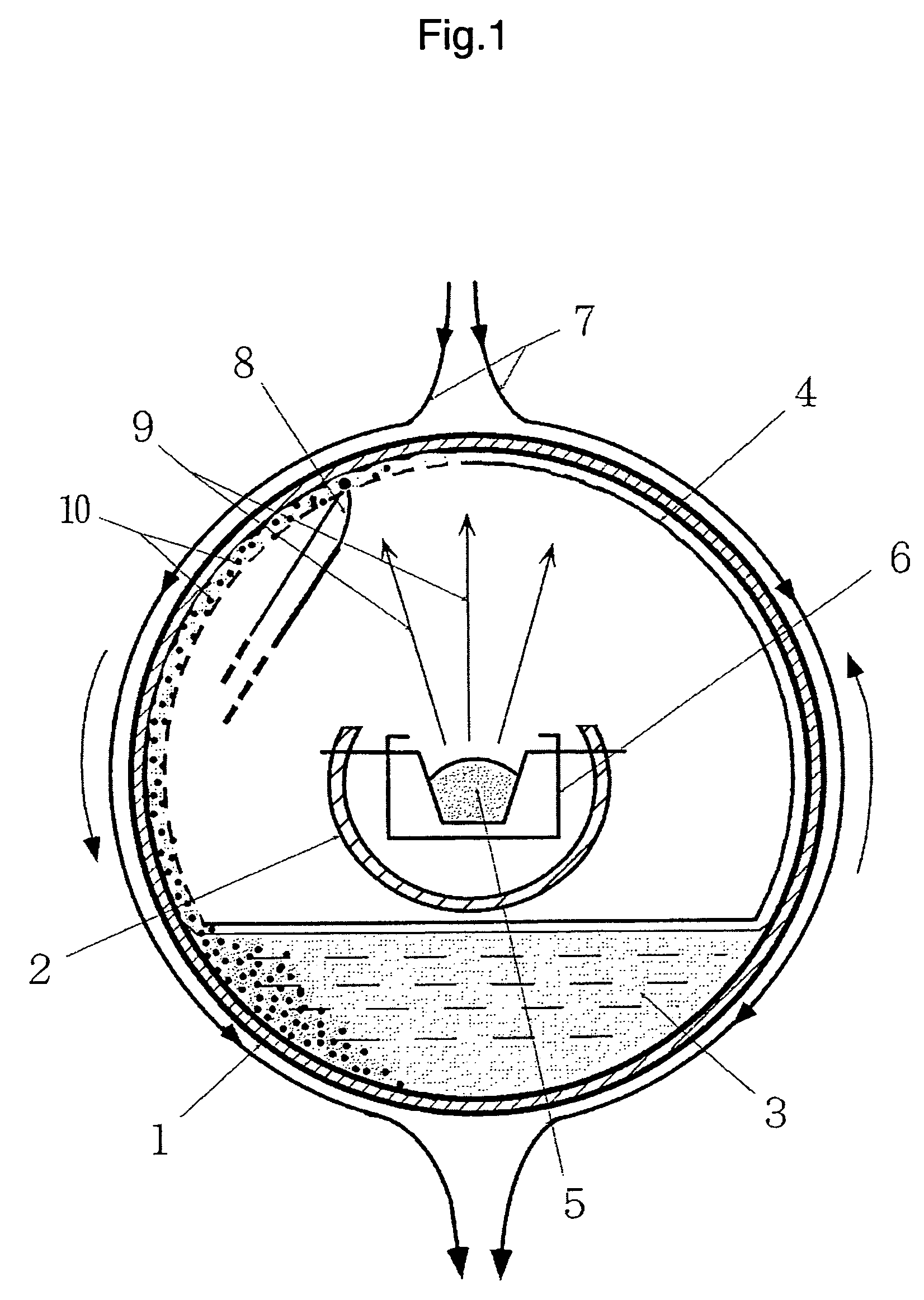

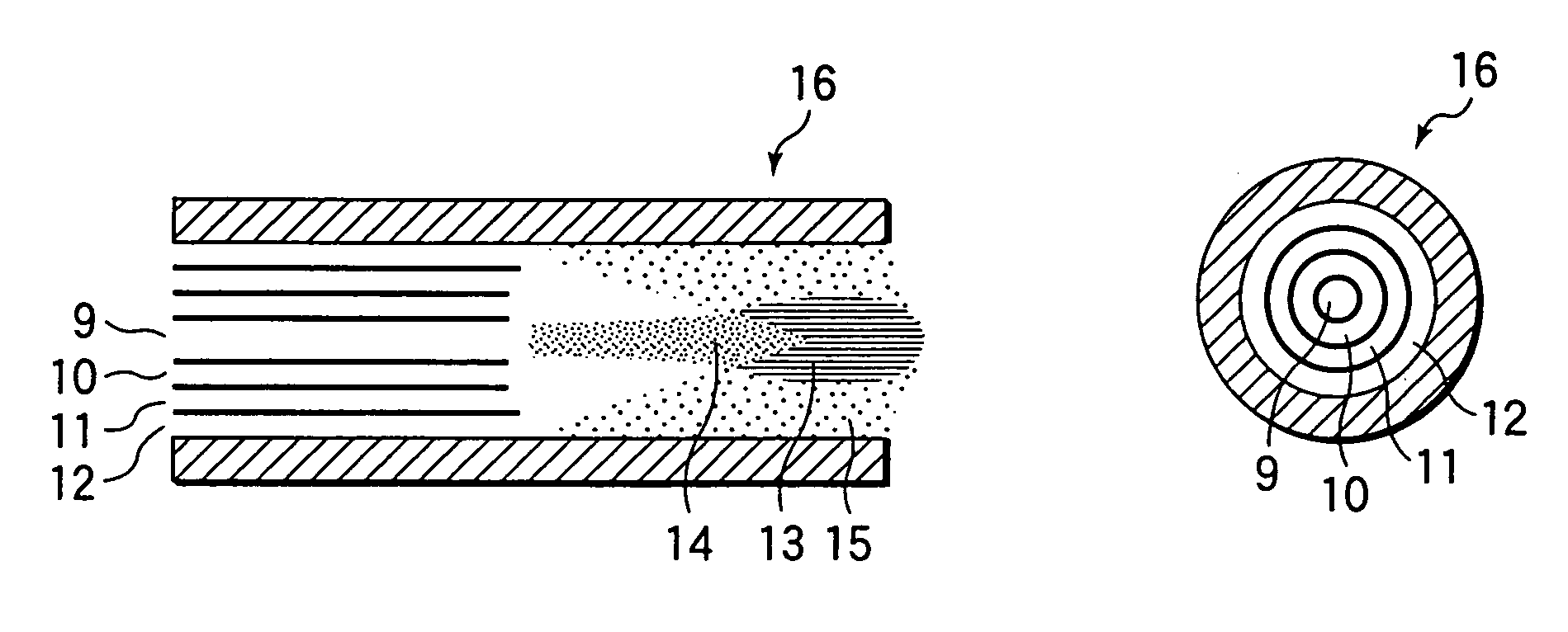

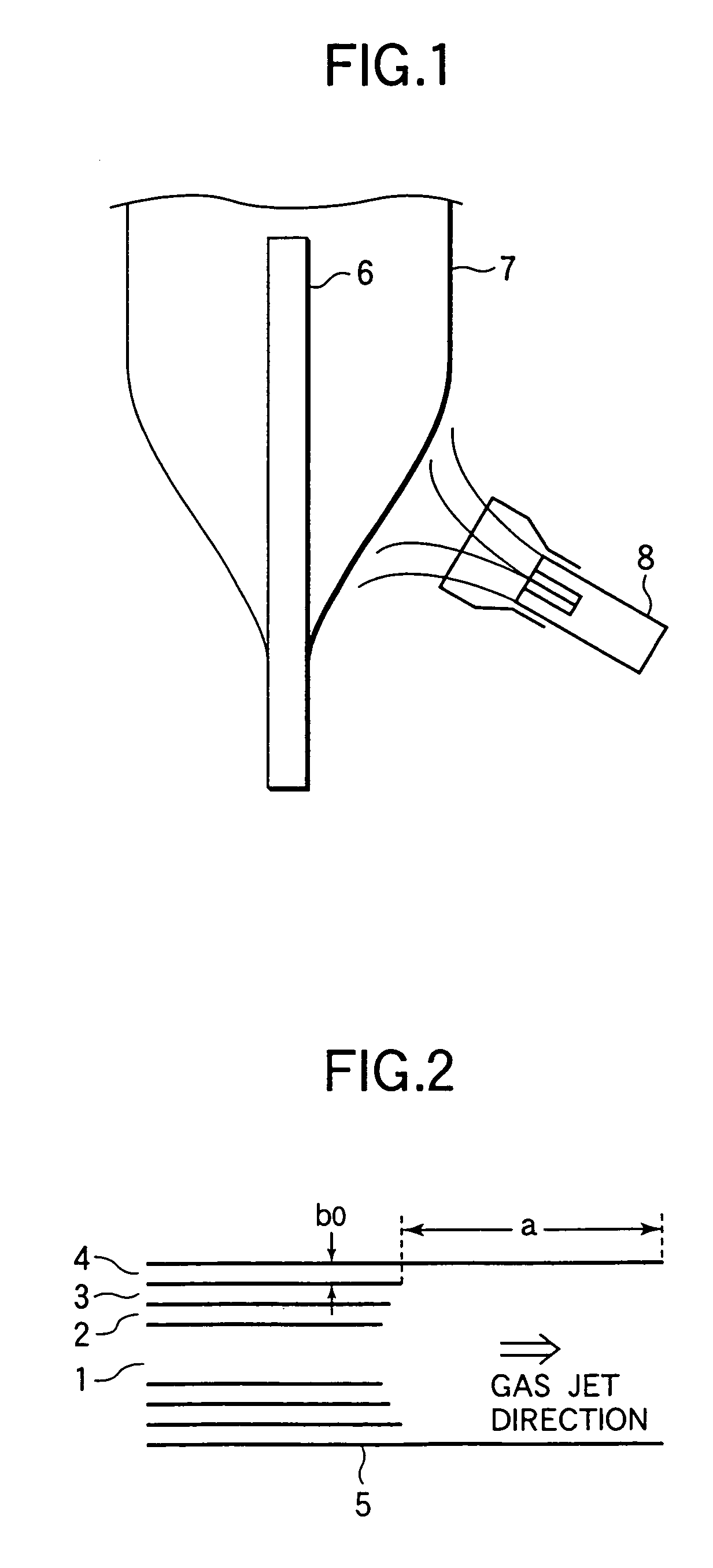

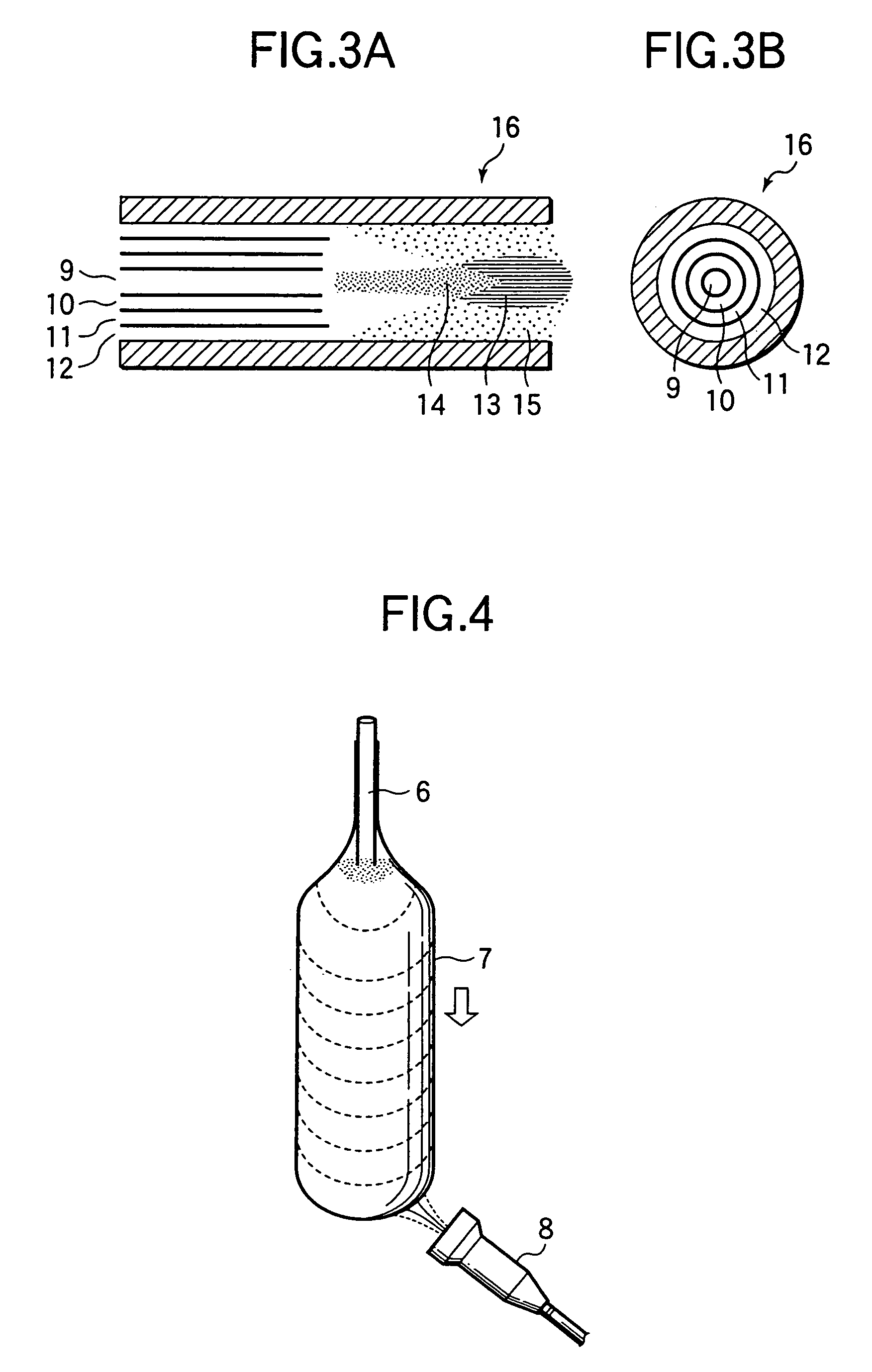

Burner for synthesizing glass particles and method for producing porous glass body

InactiveUS7143608B2Improve reaction efficiencyEfficient productionBurnersFuel lightersCombustorVitreous Bodies

A concentric multi-tubular burner for synthesizing glass particles having a center port group constituted by a combination of jet ports of raw material gas, combustible gas and oxygen gas, wherein an outer wall of the oxygen gas jet port in the center port group protrudes more toward a burner head than an inner wall of the oxygen gas jet port. The flow rate of oxygen gas jetted from the oxygen gas jet port of the center port group is controlled to be in a proper range.

Owner:SUMITOMO ELECTRIC IND LTD

Board for stringed instrument, method of manufacturing board for stringed instrument, and stringed instrument

A board for a stringed instrument which forms a front plate or a back plate of a stringed instrument, includes: a laminated plate that is obtained by laminating a plurality of veneers having a uniform thickness by an adhesive, at least one of the veneers having a different planar shape than the other veneers, in which the laminated plate is curved to be convex toward one surface side and has a thin portion and a thick portion.

Owner:YAMAHA CORP

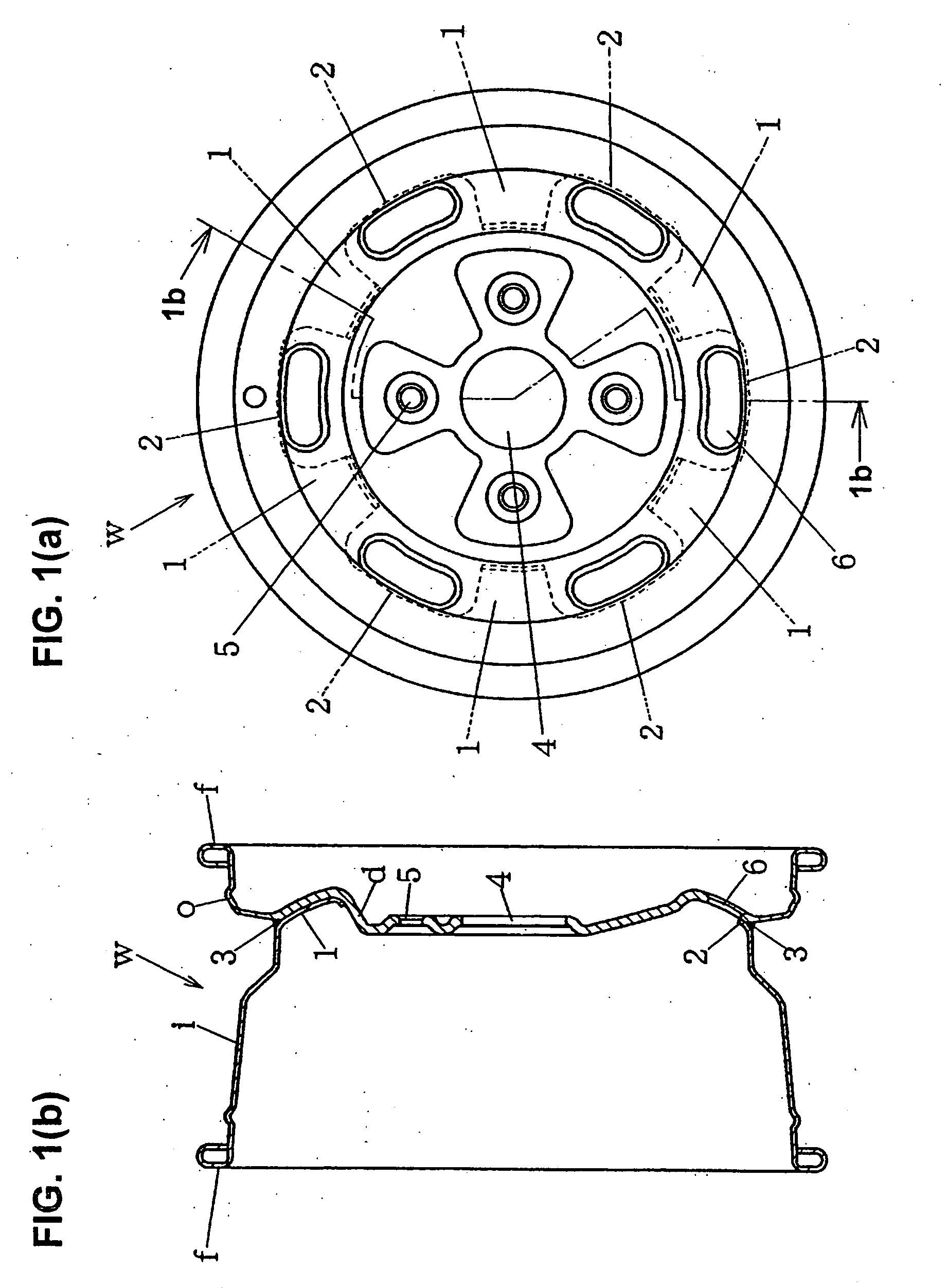

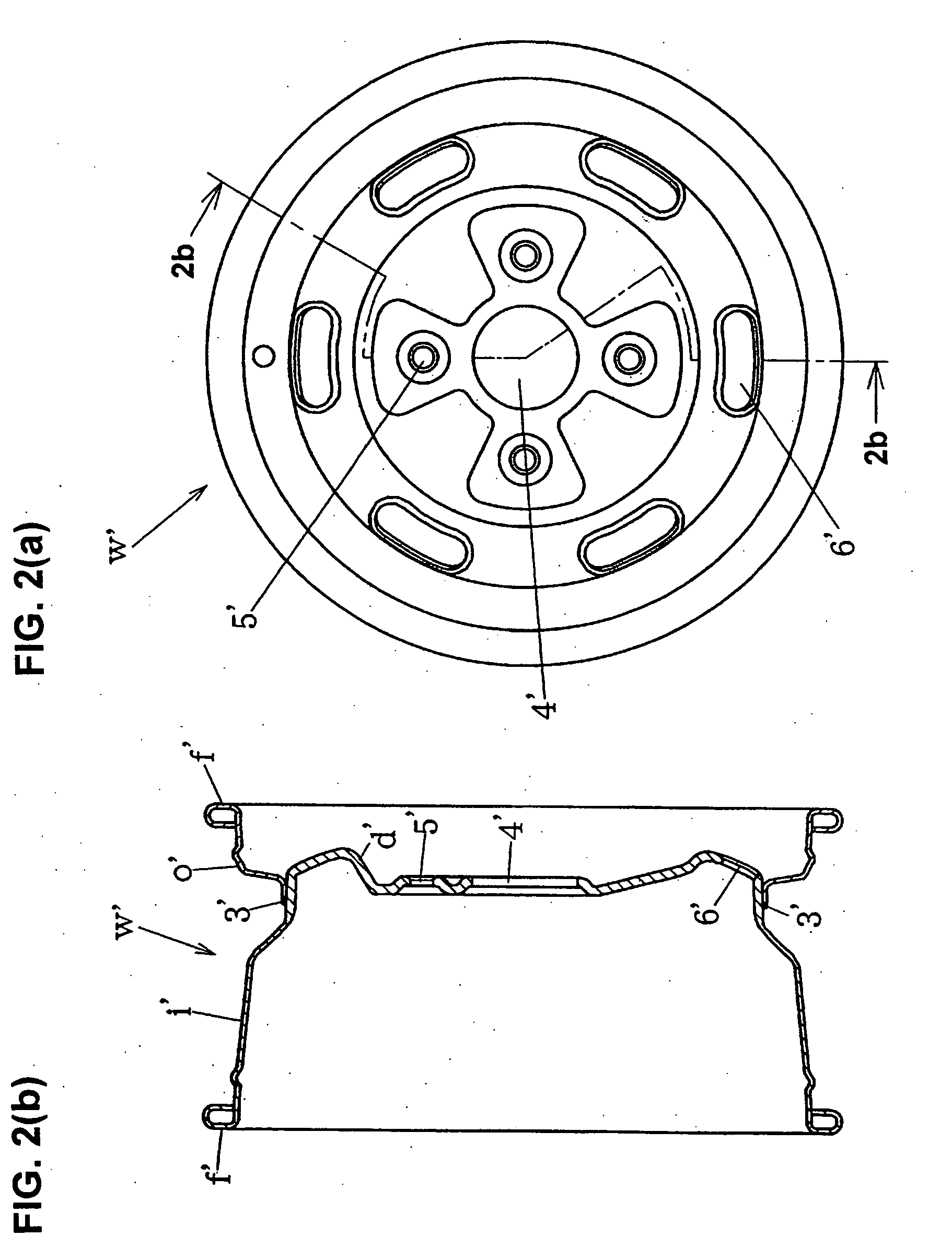

Wheel for vehicles and method for producing the same

A wheel for a vehicle including an outer rim and an inner rim, in which the outer rim is comprised of a disk section formed by embossing a first portion having a certain thickness and a rim section formed by drawing a second portion having a smaller thickness than the first portion so as to make a periphery of the disk section; and the inner rim is comprised of superimposed portions formed by drawing and to be superimposed on prescribed positions of the disk section of the outer rim. Flange sections of the outer and inner rims are respectively inwardly curled so as to form a double-layered structure. The outer and inner rims are integrated by welding with the superimposed portions set at the prescribed positions of the disk section.

Owner:ZENIYA ARUMINIUMU SEISAKUSHO K

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com