Preparation method of pore-modulatable Fe-based metal organic framework-phosphotungstic acid

A metal-organic framework and organic framework technology, applied in the field of materials, can solve problems such as limiting the application of PTA, and achieve the effects of simple preparation process and high material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Pore-tunable Fe-based metal-organic framework-phosphotungstic acid material was prepared by the following method: 50mL distilled water, 6.0mmol FeCl 3 ·6H 2 O, 0.3mmol PTA, 6.0mmol 2-aminoterephthalic acid, and 1.8mmol CTAB were stirred evenly at room temperature, then added to a 100mL polytetrafluoroethylene reactor, heated at a constant temperature of 110°C for 24h, cooled to room temperature, and then used The solid obtained after repeated washing and centrifugation with DMF and ethanol was vacuum-dried at 80°C for 16 hours, and the obtained solid was the Fe-based metal-organic framework-phosphotungstic acid material with adjustable channels.

Embodiment 2

[0026] Pore-tunable Fe-based metal-organic framework-phosphotungstic acid material was prepared by the following method: 50mL distilled water, 6.0mmol FeCl 3 ·6H 2 O, 0.3mmol PTA, 6.0mmol 2-aminoterephthalic acid, and 3.6mmol CTAB were stirred evenly at room temperature, then added to a 100mL polytetrafluoroethylene reactor, heated at a constant temperature of 110°C for 24h, cooled to room temperature, and then used The solid obtained after repeated washing and centrifugation with DMF and ethanol was vacuum-dried at 80°C for 16 hours, and the obtained solid was the Fe-based metal-organic framework-phosphotungstic acid material with adjustable channels.

Embodiment 3

[0028] Pore-tunable Fe-based metal-organic framework-phosphotungstic acid material was prepared by the following method: 50mL distilled water, 6.0mmol FeCl 3 ·6H 2 O, 0.3mmol PTA, 6.0mmol 2-aminoterephthalic acid, 5.4mmol CTAB, 7.2mmolTMB were stirred evenly at room temperature, then added to a 100mL polytetrafluoroethylene reactor, heated at 110°C for 24h, and cooled to room temperature Finally, the solid obtained after repeated washing and centrifugation with DMF and ethanol was vacuum-dried at 80°C for 16 hours, and the obtained solid was the Fe-based metal-organic framework-phosphotungstic acid material with adjustable channels.

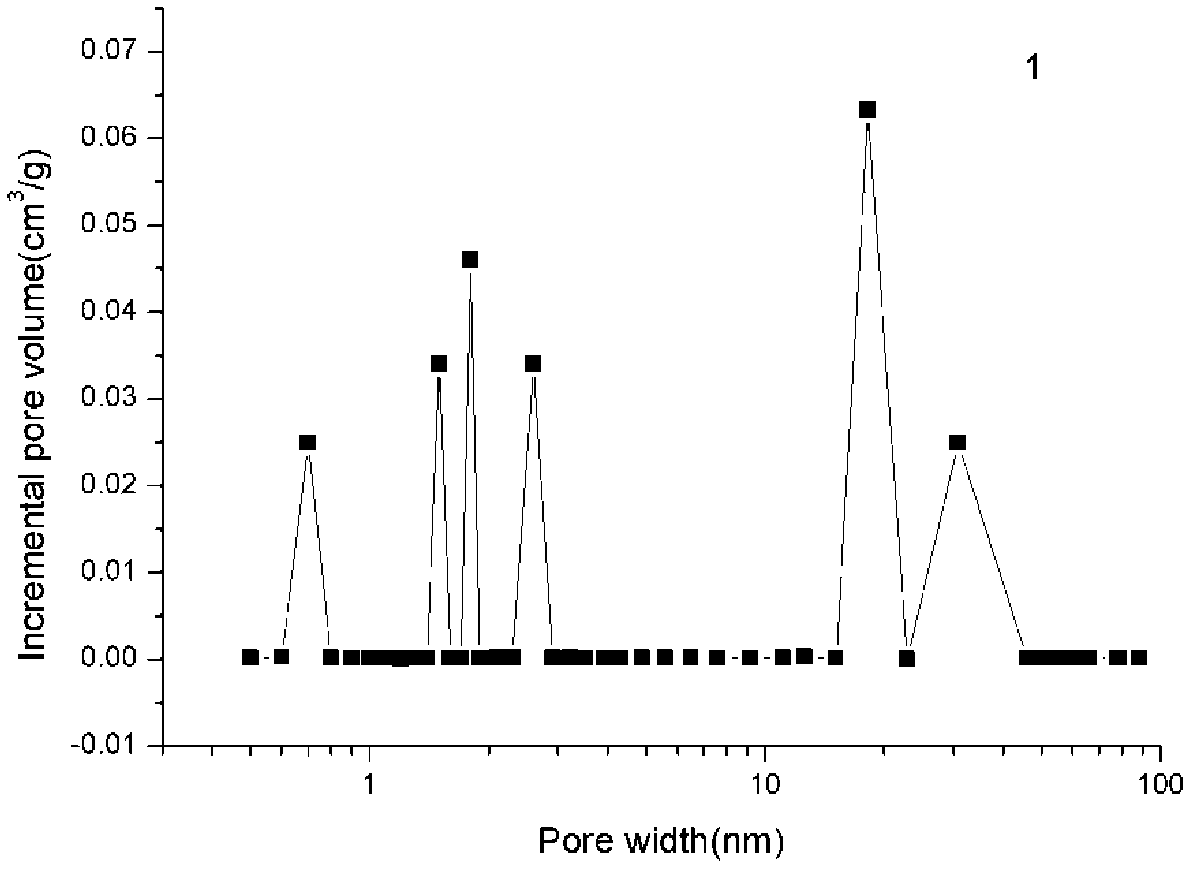

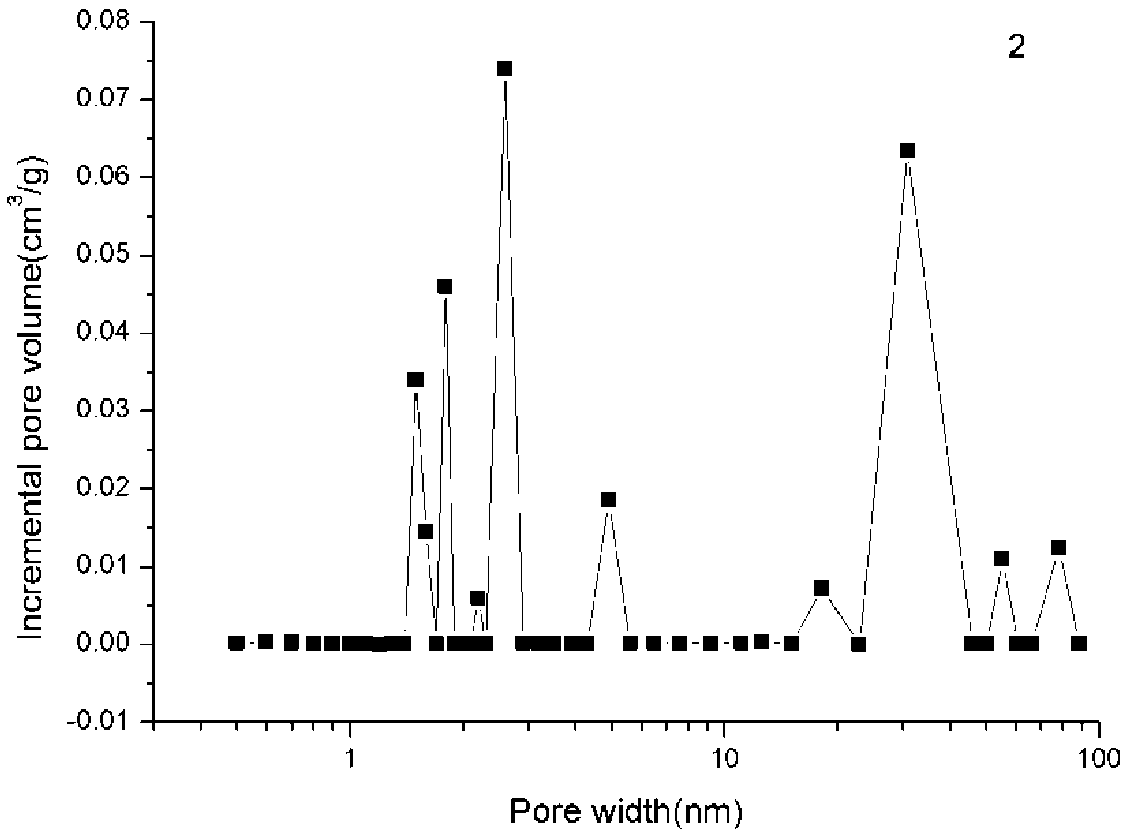

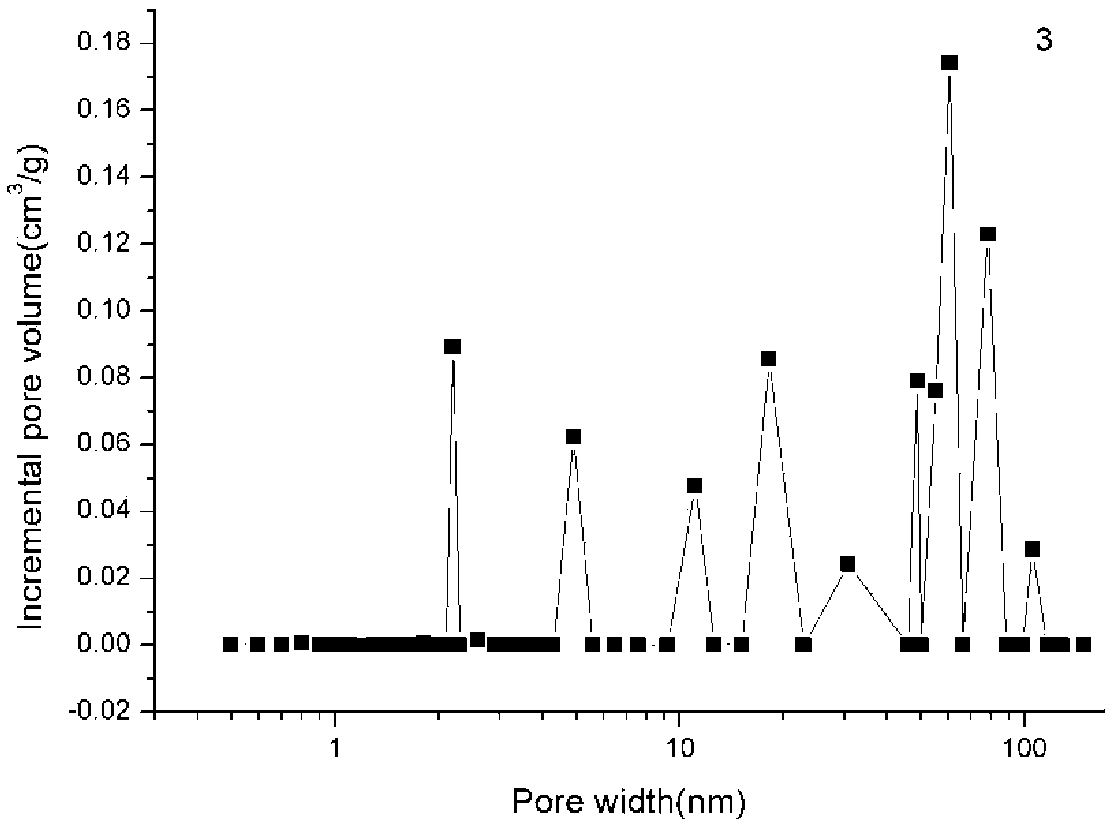

[0029] The pore size distribution figure of embodiment 1~2 gained material is as follows figure 1 with figure 2 As shown, it can be seen that the products added with CTAB all have a large-meso-microporous structure, wherein the material pore size distribution obtained in Examples 1 to 2 is 1.4 to 78.2nm, and the ratio of large-meso-micropores ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com