Lead frame and power module

A lead frame and lead technology, applied in electrical components, semiconductor devices, electric solid devices, etc., can solve the problems of low material yield and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of a lead frame and a power module to which the present invention is applied will be described below.

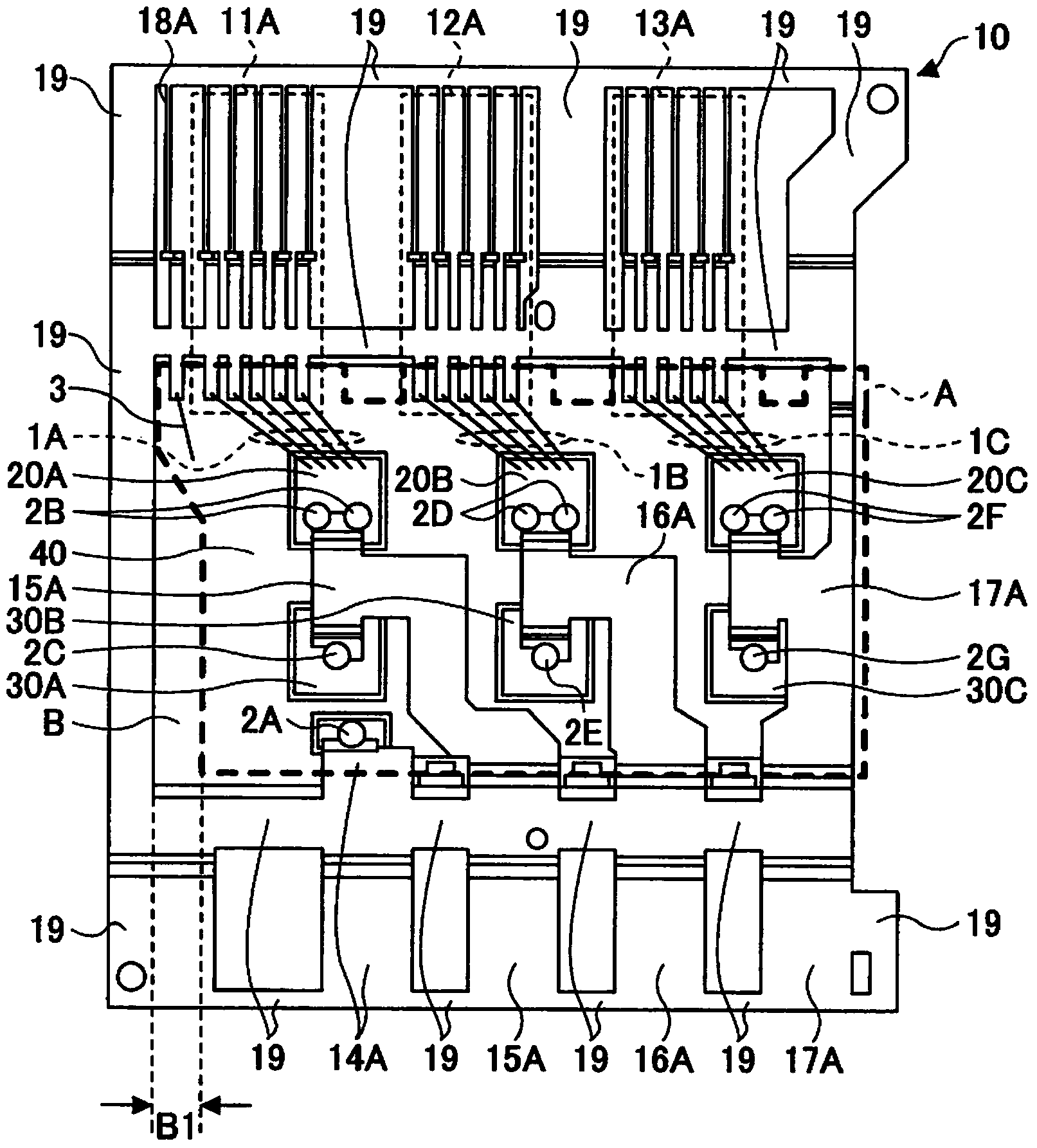

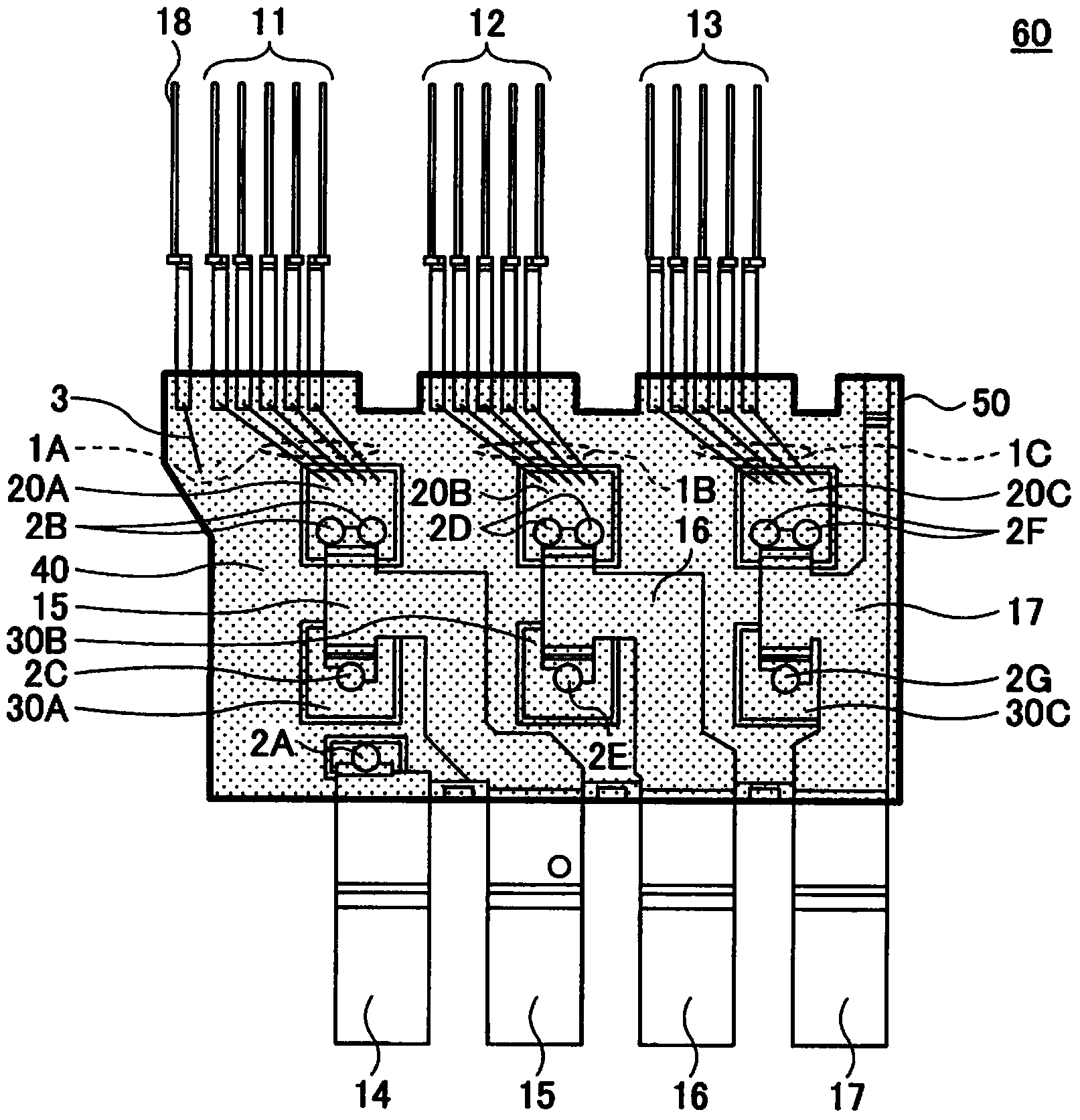

[0027] First, before describing the lead frame and the power module of the embodiment, the figure 1 and figure 2 , the lead frame of the comparative example will be described.

[0028] figure 1 is a diagram showing a state where IGBTs (Insulated Gate Bipolar Transistor: insulated gate bipolar transistors) 20A to 20C and diodes 30A to 30C are connected to the lead frame 10 of the comparative example. For the diodes 30A to 30C, for example, FWDs (Fly Wheel Diodes: freewheeling diodes) may be used.

[0029] The lead frame 10 of the comparative example includes signal lead portions 11A, 12A, and 13A, power lead portions 14A, 15A, 16A, and 17A, and a voltage detection lead portion 18A. In the lead frame 10, cut off after passing through, as signal lead parts 11, 12, 13, power lead parts 14, 15, 16, 17 and voltage detection lead part 18 (refer to figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com