Preparation method of pine needle flavone

A technology of pine needles and flavonoids, applied in the direction of anti-toxins, medical raw materials derived from gymnosperms, drug combinations, etc., can solve problems such as difficult operation, low efficiency, and pine needle damage, and achieve good product quality, high equipment requirements, The effect of mild enzymatic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of raw materials: select the larch needles of Masson pine produced in Zhejiang Province, remove the impurities, wash and dry at 60°C, and turn it from time to time. After the pine needles become brittle, take them out and crush them, sieve them, and take 20- 40 mesh, 40-100 mesh, 100-150 mesh, 150-200 mesh, 200-300 mesh, more than 300 mesh powder, refrigerated and ready for use.

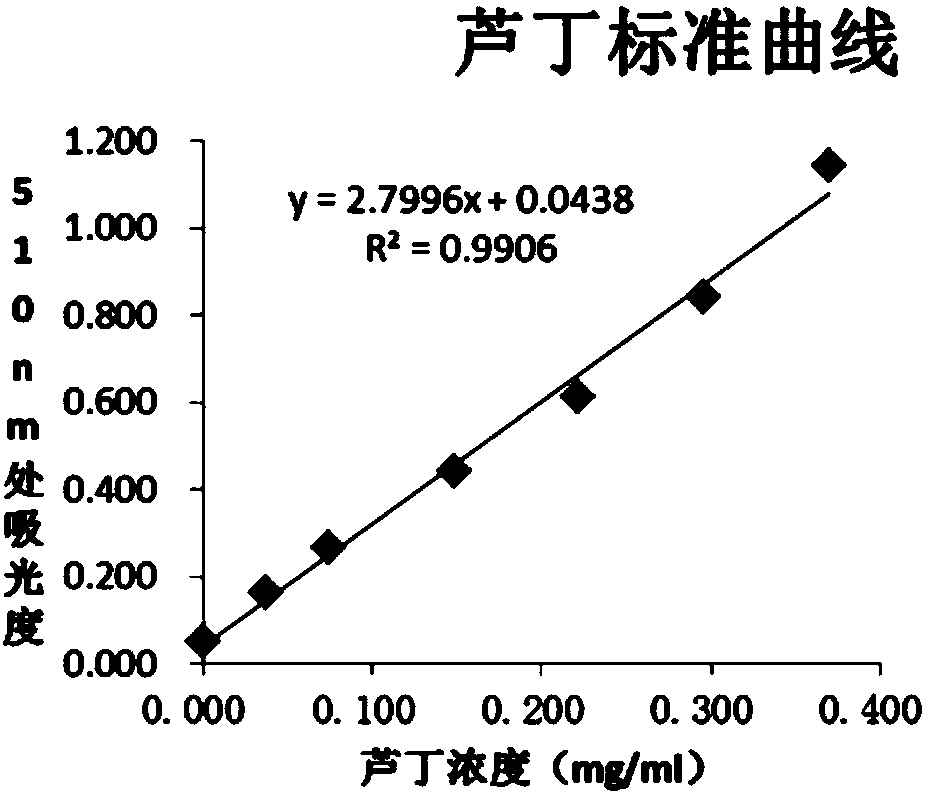

[0043] 2. Reagents: ethanol, standard rutin, sodium nitrite, aluminum nitrate, sodium hydroxide, hemicellulase (3000u / g), cellulase (40000u / g).

[0044] 3. Instruments: HMB-701C pulverizer, H1650 high-speed centrifuge, DZF-6050 vacuum drying oven, DK-8D electric heating constant temperature water tank (temperature fluctuation: ±0.5°C), RE-52A rotary evaporator, AL-104 electronic balance ( Graduation value: 0.0001g), UV-2100 ultraviolet-visible spectrophotometer, HH-2 digital display constant temperature water bath, ZXE-Z rotary vane vacuum pump, vortex oscillator, etc.

[0045]...

Embodiment 2

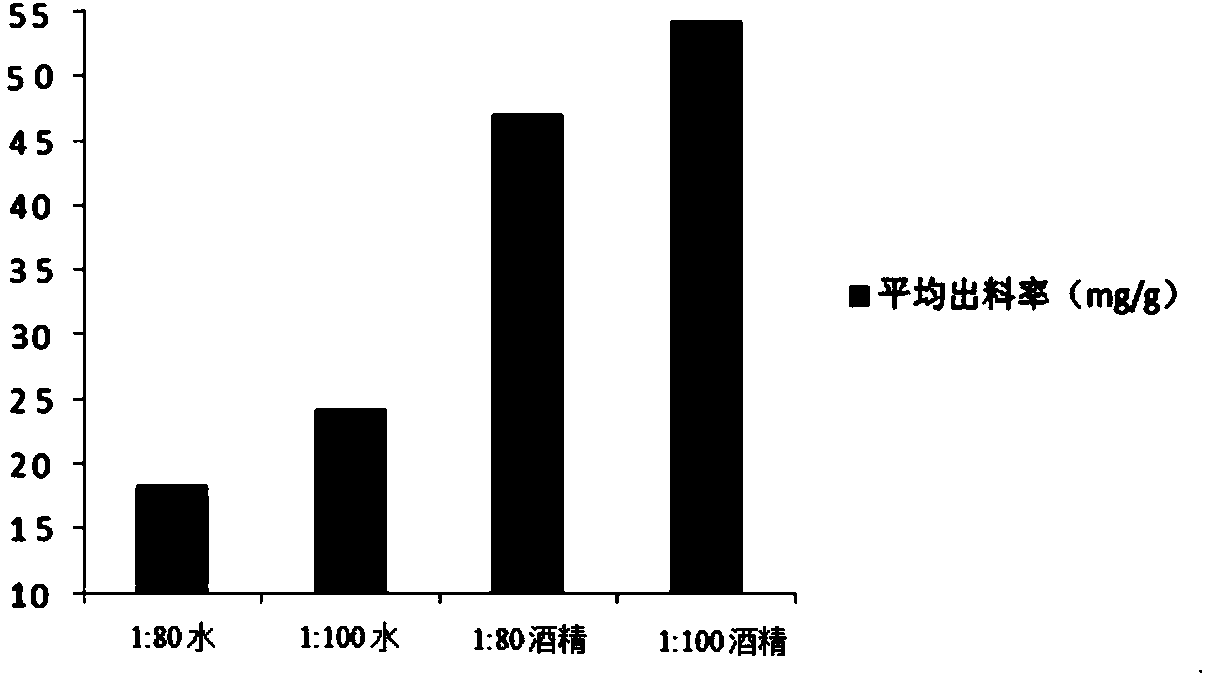

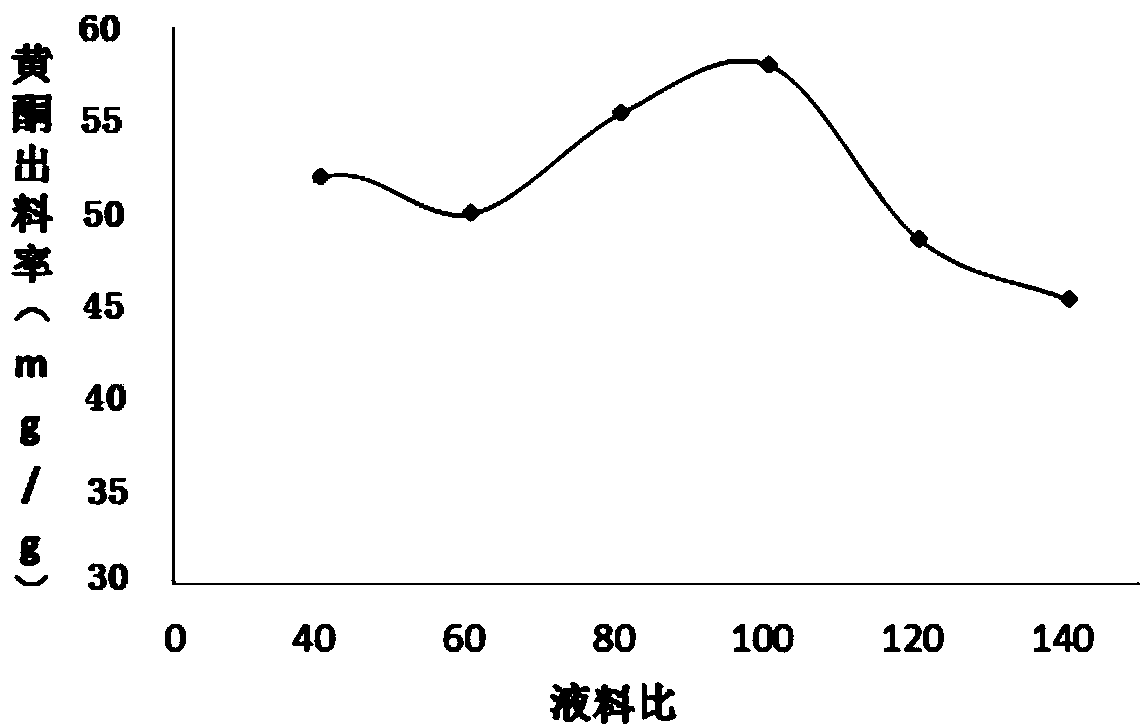

[0136] Processing of raw materials: Take 10g of dry pine needle powder (with a particle size of 150-200 mesh), add citric acid-sodium citrate buffer solution (0.1mol / L) 40 times the mass of pine needle dry powder (400g), mix well to obtain a mixture , add 0.1% cellulase (enzyme activity: 40000u / g) in the mass of the mixture, and ultrasonically hydrolyze for 120 minutes at 45°C and pH 5.0, then add 5% hemicellulase (enzyme activity) in the mass of the mixture 3000u / g), raise the temperature to 50°C, and then ultrasonically hydrolyze for 90 minutes, raise the temperature to 90°C and keep it for 5 minutes, then lower it to 80°C, add 700g of 79% ethanol aqueous solution for extraction, ethanol aqueous solution and lemon The mass ratio of the total mass of the acid-sodium citrate buffer solution to the dry powder of pine needles is 110:1, extracted at a temperature of 78°C for 128min, then centrifuged, and the flavonoid content in the supernatant was detected to be 72.24mg / g, filter...

Embodiment 3

[0138] Processing of raw materials: Take 10g of dry pine needle powder (with a particle size of 150-200 mesh), add citric acid-sodium citrate buffer solution (0.1mol / L) 40 times the mass of pine needle dry powder (400g), mix well to obtain a mixture , add 0.5% cellulase (enzyme activity: 40000u / g) in the mass of the mixture, and ultrasonically hydrolyze for 90 minutes at 45°C and pH 5.0, then add 1% hemicellulase in the mass of the mixture (enzyme activity 3000u / g), raise the temperature to 55°C, and then ultrasonically hydrolyze for 150min, then raise the temperature to 90°C and keep it for 5min, then lower it to 80°C, add 700g of 79% ethanol aqueous solution for extraction, ethanol aqueous solution and lemon The mass ratio of the total mass of the acid-sodium citrate buffer solution to the dry powder of pine needles is 110:1, extracted at a temperature of 78°C for 128min, and then centrifuged to detect that the flavonoid content in the supernatant is 69.17mg / g, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com