Strain capable of producing compound enzyme and method of using same to prepare compound enzyme for weaned piglets

A technology of weaned piglets and compound enzymes, applied in the biological field, can solve problems such as intestinal damage, difficulty in digesting and absorbing feed, piglet diarrhea, etc., and achieve the effects of promoting healthy growth, promoting decomposition, digestion, absorption and utilization, and eliminating harmful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

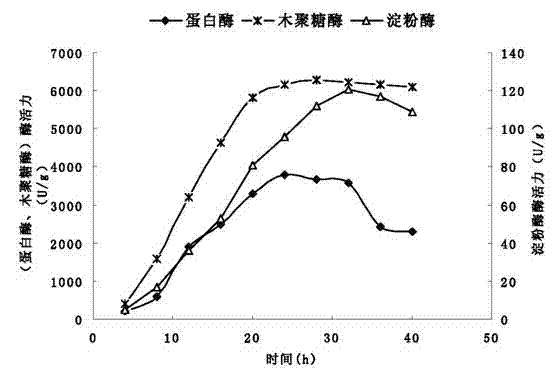

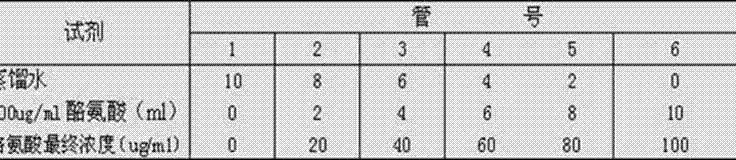

[0024] Aspergillus niger strain CGMCC No.6027 was fermented in a 100L solid fermenter to produce enzymes, and a ring of CGMCC No.6027 strains was added from the slant surface of the slant preservation medium to the slant surface of the primary seed medium to activate the strains. 32°C, after 72h to 96h of cultivation time, connect the three-ring first-level seed strains from the slant of the first-level seed medium into the second-level seed medium (secondary seed medium 60g / 1000mL triangular flask), at 28-32 °C, after 65h-84h of culture time, the inoculation amount of 0.2% of the weight of the fermentation medium was inserted into the fermentation medium in a 100L solid fermenter. The fermentation medium in the 100L solid fermenter is 50Kg, the temperature is 29°C, the relative humidity is above 90%, and the fermentation time is 24-32h. The aseptic air conditioning system and full atomization water replenishment system were opened in time to realize temperature self-control a...

Embodiment 2

[0027] Aspergillus niger strain CGMCC No.6027 was fermented in a 100L solid fermenter to produce enzymes, and a ring of CGMCC No.6027 strains was added from the slant surface of the slant preservation medium to the slant surface of the primary seed medium to activate the strains. 32°C, after 72h to 96h of cultivation time, connect the three-ring first-level seed strains from the slant of the first-level seed medium into the second-level seed medium (secondary seed medium 60g / 1000mL triangular flask), at 28-32 °C, after 65h-84h of culture time, the inoculation amount of 0.2% of the weight of the fermentation medium was inserted into the fermentation medium in a 100L solid fermenter. The fermentation medium in the 100L solid fermenter is 50Kg, the temperature is 29°C, the relative humidity is above 90%, and the fermentation time is 24-32h. The aseptic air conditioning system and full atomization water replenishment system were opened in time to realize temperature self-control a...

Embodiment 3

[0030] Aspergillus niger strain CGMCC No.6027 was fermented in a 100L solid fermenter to produce enzymes, and a ring of CGMCC No.6027 strains was added from the slant surface of the slant preservation medium to the slant surface of the primary seed medium to activate the strains. 32°C, after 72h to 96h of cultivation time, connect the three-ring first-level seed strains from the slant of the first-level seed medium into the second-level seed medium (secondary seed medium 60g / 1000mL triangular flask), at 28-32 °C, after 65h-84h of culture time, the inoculation amount of 0.2% of the weight of the fermentation medium was inserted into the fermentation medium in a 100L solid fermenter. The fermentation medium in the 100L solid fermenter is 50Kg, the temperature is 29°C, the relative humidity is above 90%, and the fermentation time is 24-32h. The aseptic air conditioning system and full atomization water replenishment system were opened in time to realize temperature self-control a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com