Method for preparing high-density fused quartz ceramic

A technology of fused silica and density, applied in the field of powder metallurgy, can solve the problems of material thermal stability decline, material sintering unfavorable, low strength, etc., and achieve the effect of improving ceramic density, rich raw materials, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

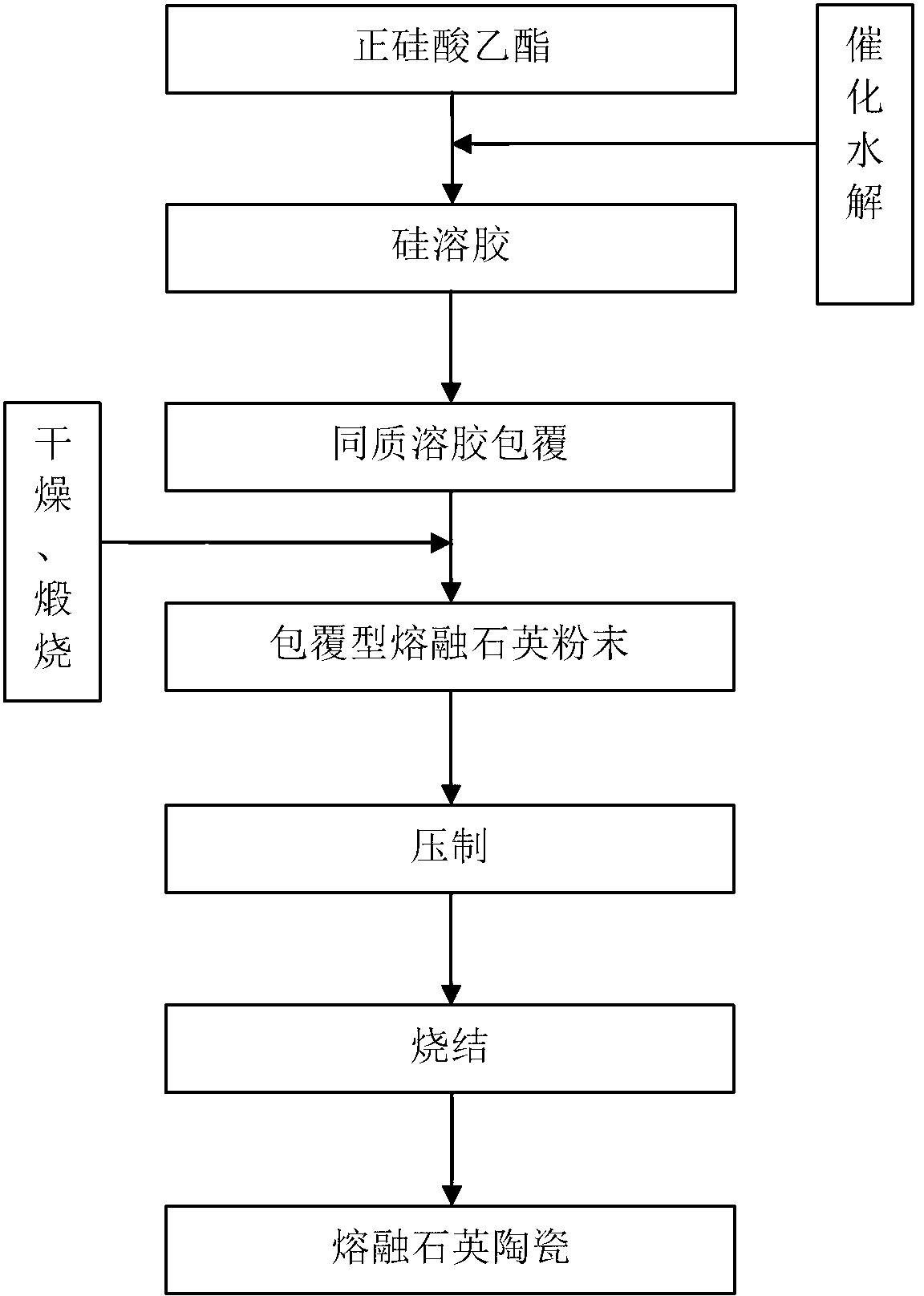

[0025] 1. Preparation of coated fused silica powder

[0026] Using isopropanol as a co-solvent, under the action of a strong stirrer, use 0.02mol / L hydrochloric acid to catalyze the hydrolysis of 5ml of tetraethyl orthosilicate, heat in a water bath at 45°C, react for 3 hours to form a silica sol, and then the ultrasonically dispersed Put the fused silica powder into the beaker and continue to stir for 4 hours to complete the coating; after the experiment, the samples were washed, filtered, dried and ground;

[0027] 2. Calcination

[0028] The surface-coated powder is placed in a calcination furnace, the calcination temperature is 600° C., and the calcination time is 2 hours, to obtain a surface-coated powder for pressing and sintering;

[0029] 3. Densification

[0030] The homogeneous sol-coated fused silica powder is pressed and sintered to obtain a high-density fused silica ceramic material.

[0031] 1) Compression: molding is adopted, the compression pressure of moldi...

Embodiment 2

[0034] 1. Preparation of coated fused silica powder

[0035] Using isopropanol as a co-solvent, under the action of a strong stirrer, use 0.03mol / L hydrochloric acid to catalyze the hydrolysis of 10ml of tetraethyl orthosilicate, heat in a water bath at 60°C, react for 4 hours to form a silica sol, and then melt the ultrasonically dispersed Put the quartz powder into the beaker and continue to stir for 4 hours to complete the coating; after the experiment, the samples were washed, filtered, dried and ground;

[0036] 2. Calcination

[0037] The surface-coated powder is placed in a calcination furnace with a calcination temperature of 650°C and a calcination time of 2 hours to obtain a surface-coated powder for pressing and sintering;

[0038] 3. Densification

[0039] The homogeneous sol-coated fused silica powder is pressed and sintered to obtain a high-density fused silica ceramic material.

[0040] 1) Compression: Cold isostatic pressing is adopted, the pressing pressure...

Embodiment 3

[0043] 1. Preparation of coated fused silica powder

[0044] Using isopropanol as a co-solvent, under the action of a strong stirrer, use 0.03mol / L hydrochloric acid to catalyze the hydrolysis of 15ml of tetraethyl orthosilicate, heat in a water bath at 70°C, react for a period of 4 hours to form a silica sol, and then ultrasonically disperse Put the good fused silica powder into the beaker and continue to stir for 5 hours to complete the coating; after the experiment, the samples were washed, filtered, dried and ground;

[0045] 2. Calcination

[0046] The surface-coated powder is placed in a calcination furnace, the calcination temperature is 700° C., and the calcination time is 2 hours, to obtain a surface-coated powder for pressing and sintering;

[0047] 3. Densification

[0048] The homogeneous sol-coated fused silica powder is pressed and sintered to obtain a high-density fused silica ceramic material.

[0049] 1) Compression: molding is adopted, the compression pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com