Special forging method suitable for super duplex stainless steel bars

A duplex stainless steel, a special technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, heating/cooling equipment, etc., can solve the problems of large energy consumption, poor steel plasticity, and many times of forging fires, and achieve energy consumption Low cost, high production efficiency, and high material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

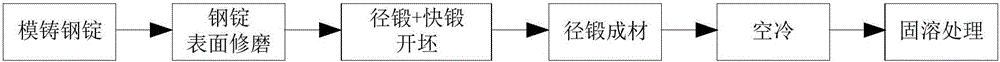

[0057] A special forging process for super duplex stainless steel bars, comprising the following steps:

[0058] (1) Firstly, it is smelted by electric furnace + AOD furnace, and cast into a 3.0T steel ingot. The specifications of the steel ingot are: upper section 550mm×550mm, lower section 466mm×466mm, height 1675mm.

[0059] (2) Then the steel ingot is sent into the annealing furnace for stress relief annealing, the annealing temperature is 920°C, and the annealing time is 18h.

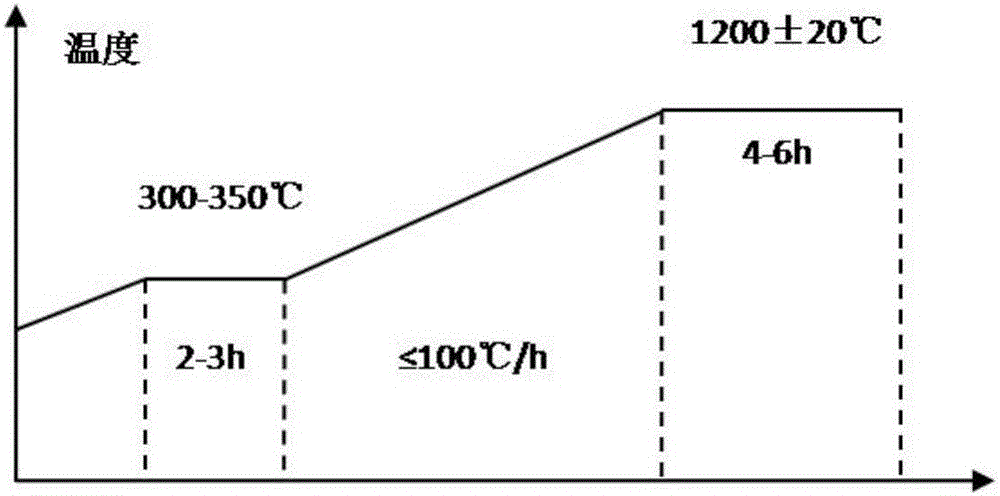

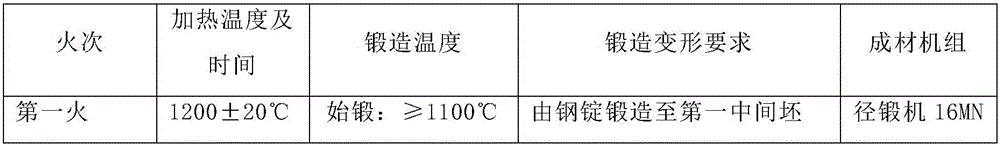

[0060] (3) The first fire time: heat the steel ingot in a chamber furnace, first raise the temperature to about 320°C, and keep it warm for 2.5h, then raise the temperature to about 1200°C at a speed of 80°C / h, and keep it warm for 4.5-5.5 h. After being out of the furnace, use a trackless discharge car to quickly clamp it out and transfer it to a 16MN radial forging machine. The initial forging temperature is 1100-1120°C. On the radial forging machine, the electric furnace ingot is forged into th...

Embodiment 2

[0080] This embodiment adopts the same raw materials and process parameters as in Embodiment 1, and the forged product is a Φ180mm bar, wherein the compression ratio from the steel ingot to the first intermediate billet is 1.8 (3.0t ingot is punched into a 430 round billet), and the first The compression ratio of the intermediate billet to the second intermediate billet obtained after fast forging and opening is 2.4 (from 430 round billet to 280 round billet), and the compression ratio from the second intermediate billet to the finished bar is 2.4 (from 430 round billet to 180 bars). The yield of this embodiment is 98%.

Embodiment 3

[0082] (1) First smelted by electric furnace + AOD furnace, die cast into 1.6T steel ingot, steel ingot specifications: upper section 470mm×470mm, lower section 360mm×360mm, height 1500mm, chemical composition is the same as Example 1, forging heating and initial forging and final forging The temperature is the same as in Example 1, but the forged product is a bar of Φ100mm, wherein the compression ratio from the steel ingot to the first intermediate billet is 1.95 (from the 1.6T ingot to the 360 round billet), and after the first intermediate billet to the rapid forging billet opening The obtained second intermediate billet has a compression ratio of 3.56 (from a 360 round billet to a 180 round billet), and a compression ratio from the second intermediate billet to the finished rod is 3.24 (from a 180 round billet to a 100 round billet). The yield of this embodiment is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com