Electrically conductive fabric and manufacturing method and apparatus thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

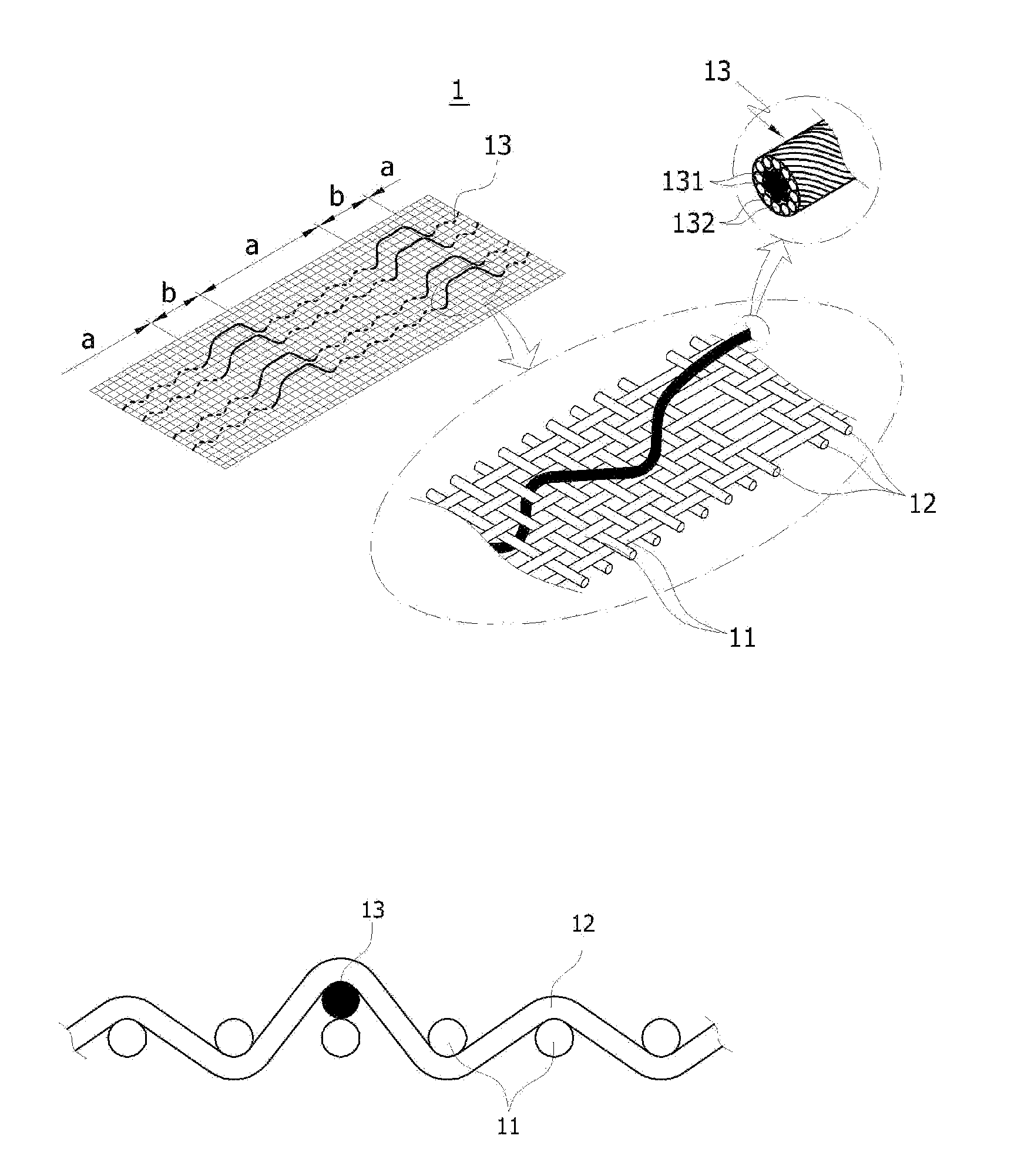

first embodiment

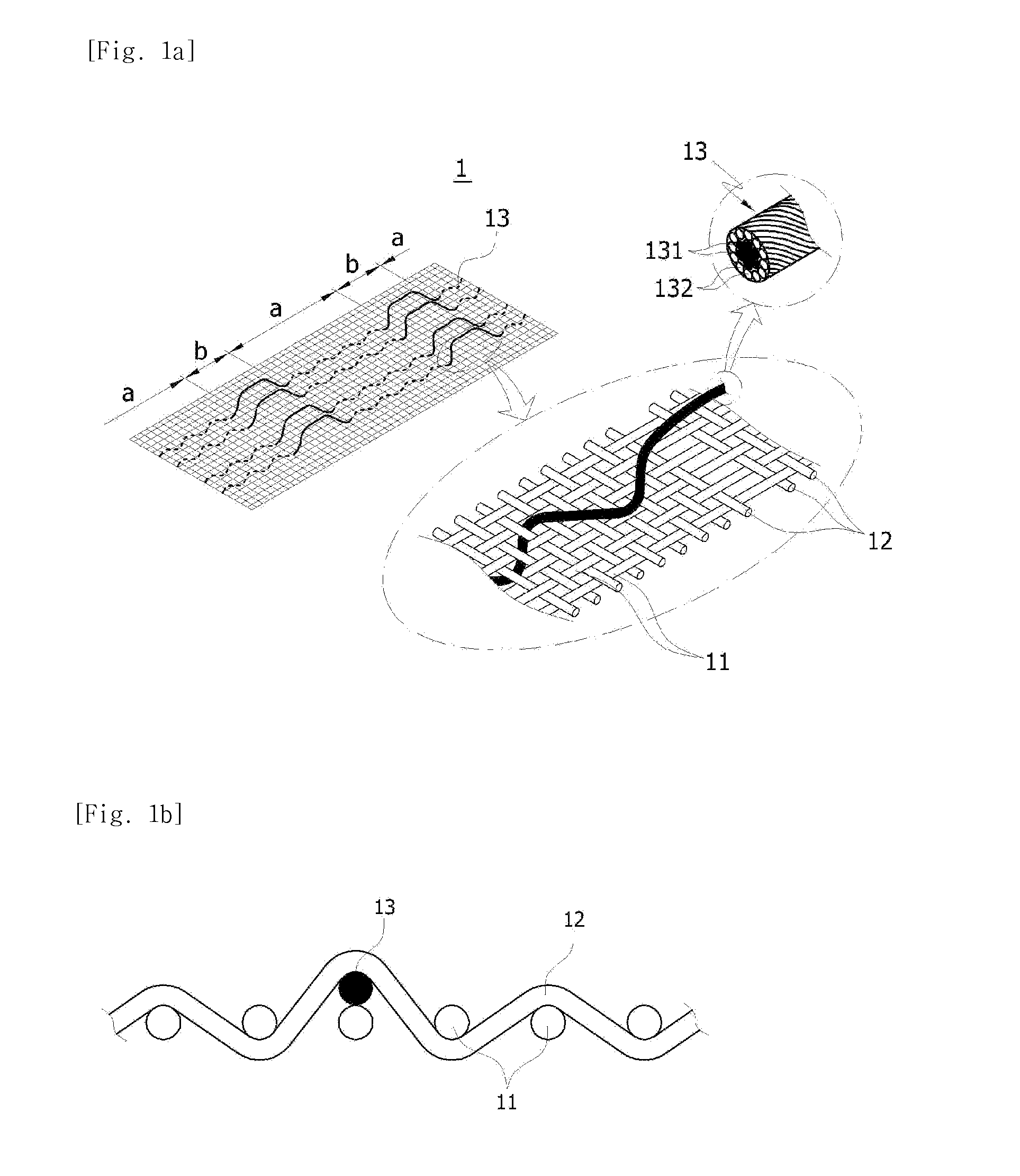

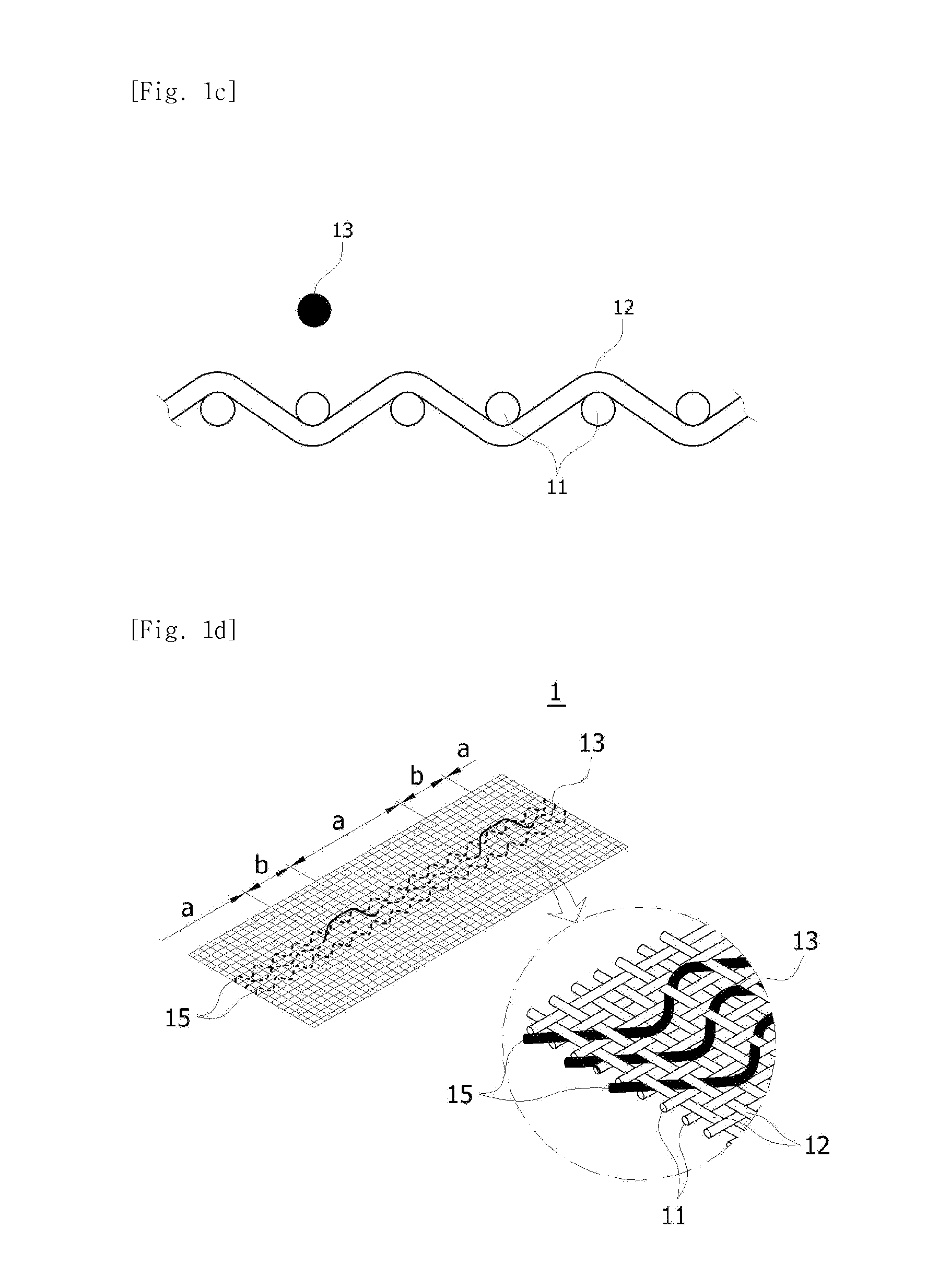

[0045]Next, FIG. 1d is a view showing the first modification of the electrically conductive fabric according to the present invention; as shown in the drawing, the electrically conductive fabric includes support wires 15 which are woven along the placement path of the electrically conductive wire.

[0046]The support wires 15 are woven on the left and right of the electrically conductive wire 13 to bind it to the warp and weft so as to prevent deformation. Namely, if the electrically conductive wire 13 is composed of metal yarn, it is protruded to the surface or back of the electrically conductive fabric 1 due to the difference in flexibility from the fiber yarn supplied as the weft and warp. At this time, since the support wires 15 perform the function of holding the weft and warp on the left and right as reinforcement wires, the twist of the electrically conductive wire can be prevented. For this purpose, it is preferable that the support wire 15 has a plurality of fiber yarns twiste...

second embodiment

[0053]With reference to FIGS. 2a to 2c and FIG. 2d, the electrically conductive fabric 1′ according to the present invention includes multiple strands of warp 11 arranged lengthwise, multiple strands of weft 12 knitted in the direction perpendicular to the warp 11, and plural strands of electrically conductive wires 13 arranged lengthwise and woven. At this time, the weft 12 includes a first warp-knitting weft 12a that is knitted with the warp 11 at the position corresponding to the inside of the electrically conductive wire 13, a second weft 12b (see FIG. 2d) for knitting the warp that is knitted with the warp 13 so as to provide a feeding free zone in the range of width corresponding to the placement width of the electrically conductive wire 13 at the position corresponding to the outside of the electrically conductive wire 13, and a binding-and-releasing weft 12c (see FIGS. 2b and 2c) that is knitted with the warp so as to selectively bind the electrically conductive wire 13 at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com