Pigment printing method for cashmere sweater

A pigment printing and cashmere technology, applied in the field of dyeing and finishing, can solve the problems of knitted fabrics such as high extensibility, yellowing strength, and poor capillary performance, and achieve the effects of improving the thickness and hardness of the size film, protecting the quality, and reducing the fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

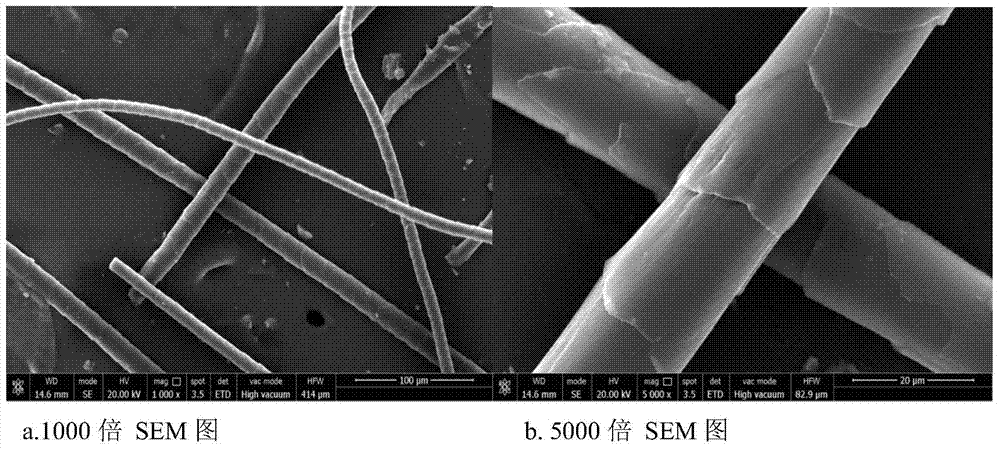

Image

Examples

Embodiment Construction

[0044] The outstanding feature of the present invention is that the present invention specifically provides following technical scheme: the method for cashmere knitted fabric paint printing, it is characterized in that: comprise the following steps:

[0045] (1) Ordinary pigment printing

[0046] ①The pulp formula is:

[0047]

[0048] ②The mixing process is as follows:

[0049] First add half the amount of synthetic thickener, then add half the amount of deionized water and stir for 5 minutes. Stir well after adding the binder. Stir thoroughly after adding the cross-linking agent. Stir thoroughly after adding the defoaming penetrant. Stir thoroughly after adding the softener. Stir well after adding paint. Add the remaining emulsified paste or synthetic thickener and water to the total weight of the color paste, and stir thoroughly.

[0050] Mixing should be carried out at a lower temperature to prevent skinning due to heat; glass containers, ceramic or plastic bucke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com