Zinc Nickel Secondary Cylindrical Alkaline Battery Cap

A technology of alkaline batteries and cylinders, which is applied to battery components, circuits, electrical components, etc., can solve problems affecting battery appearance quality, battery performance, and normal use, so as to ensure normal use performance, long service life, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be further explained by using the drawings and embodiments.

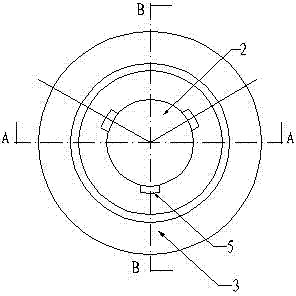

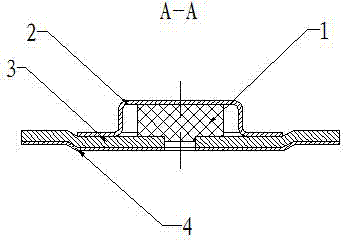

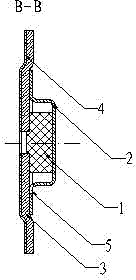

[0015] Reference Figure 1-3 The zinc-nickel secondary cylindrical alkaline battery cap of the present invention includes a valve core 1, a contact cap 2, a chassis 3 and a connecting piece 4. The surface of the contact cap 2 and the surface of the chassis 3 are both nickel-plated, the valve core 1 is placed in the cavity formed by the chassis 3 with the nickel-plated layer and the contact cap 2 with the nickel-plated layer, and the lower end of the valve core 1 has a nickel-plated layer The gas release hole of the chassis 3 is matched with the gas release hole 5 at the lower part of the contact cap 2. The nickel-plated chassis 3 and the nickel-plated contact cap 2 are spot welded and fixed, and the spot welding points are preferably uniformly distributed Of 3 points. The nickel-plated chassis 3 and the connecting piece 4 are fixedly connected by spot welding, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com