Novel environment-friendly alloy catalytic liquid and preparation method thereof

A catalytic liquid and environmentally friendly technology, applied in the field of catalytic liquid, can solve the problems of slow plating speed, unstable quality, high cost, etc., and achieve the effects of good weldability, high wear resistance, and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of a kind of novel environment-friendly alloy catalytic liquid of the present invention comprises the following steps: (1) take each raw material according to the weight percentage of raw material, for subsequent use; (2) sequentially mix nickel sulfate, sodium hypophosphite, sodium citrate , Ethyl-hydroxypropionic acid, acetic acid, sodium acetate, hydrazine sulfate, sulfur powder and water are added to the container, and stirred evenly at room temperature to form a semi-finished mixed solution; (3) ammonia and sulfuric acid are added to the semi-finished mixed solution, and the pH value is adjusted to 4.5-5.2, stir evenly to form a catalytic solution.

[0023] Before plating, the plated parts must be pretreated to remove the oil stains and oxides on the surface, and then carry out water washing→acid cleaning activation→water washing→80~90℃alloy catalyst solution immersion treatment in sequence. The soaking time in the catalytic solution is 20-30...

experiment example

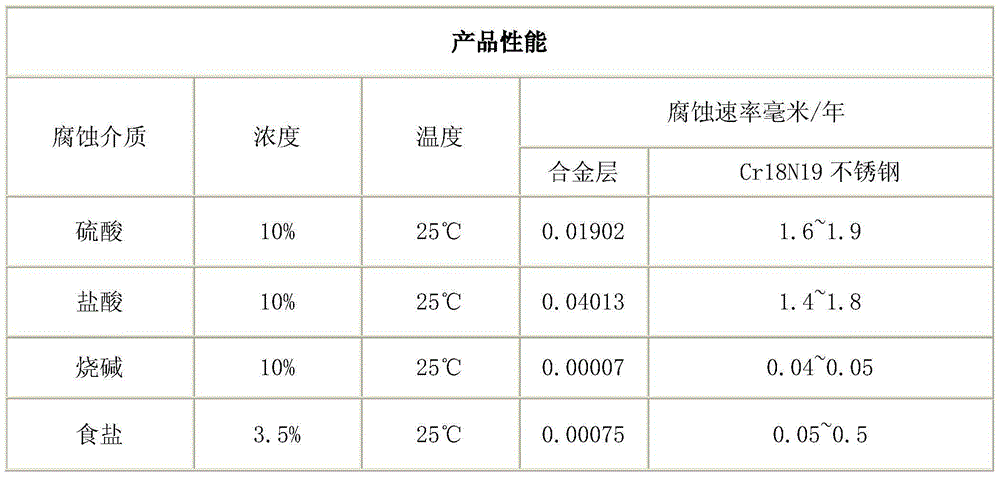

[0025] The catalytic solution was prepared according to the above formula and preparation method, and its corrosion rate was lower than that of Cr18Ni9 stainless steel through comparison tests of sulfuric acid, hydrochloric acid, caustic soda and brine. See the table below for details:

[0026] Table 1 Corrosion rate comparison table

[0027]

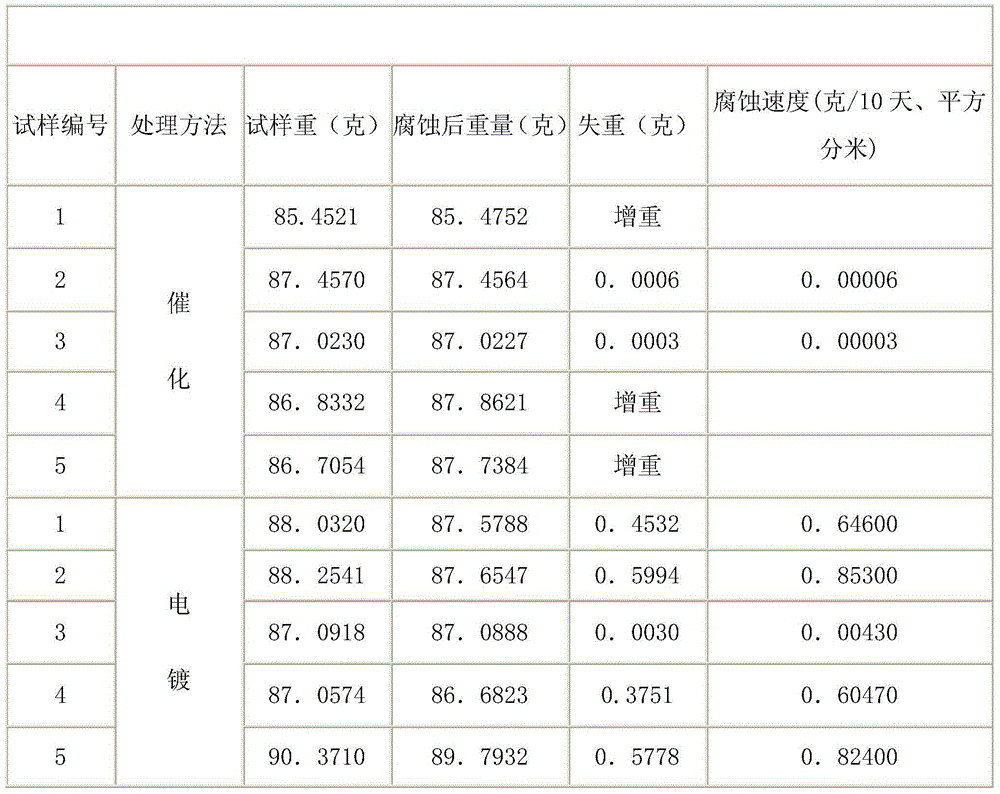

[0028] Catalytic solution was prepared according to the above formula and preparation method, five samples were electroplated with the conventional electroplating method, and then the corrosion test was carried out. The results are shown in the following table:

[0029] Table 2 Corrosion speed comparison table

[0030]

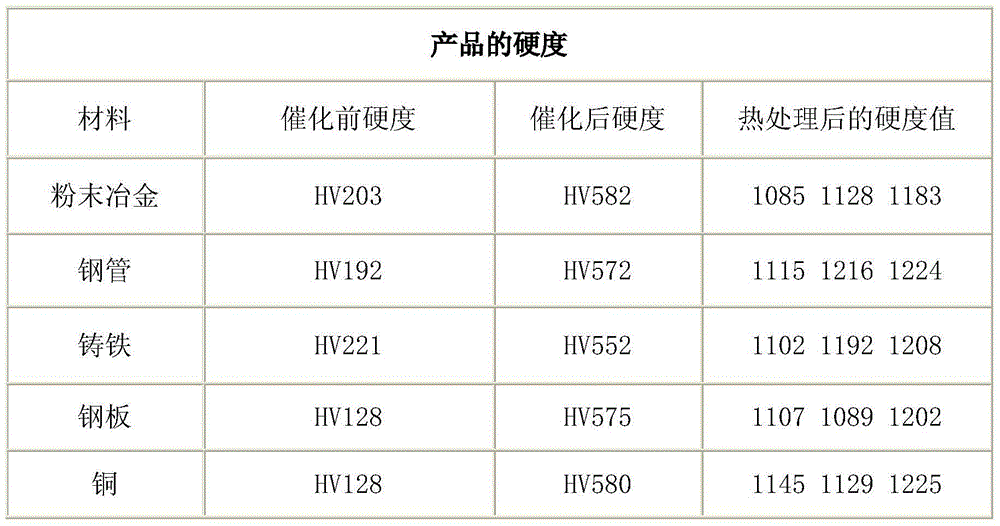

[0031] Prepare the catalytic solution according to the above formula and preparation method, and carry out catalytic electroplating on various materials. The hardness changes of various materials are as follows:

[0032] Table 3 hardness test table

[0033]

[0034] After being treated by this technology, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com