Touch screen UV curing peelable blue gel and preparing method thereof

A touch screen, blue glue technology, applied in the application, coating, ink and other directions, can solve the problems of poor acid and alkali resistance, poor flexibility, and not easy to peel off the protective adhesive, and achieve good toughness, good film formation, and easy peeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

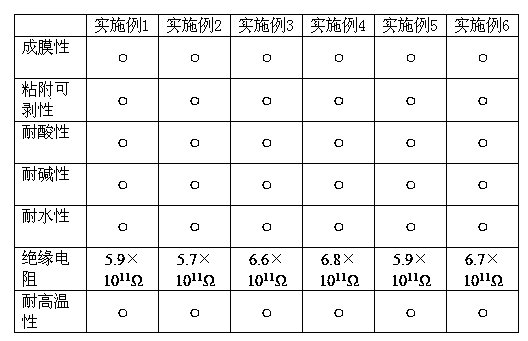

Examples

Embodiment 1

[0062] A touch screen UV curing peelable blue glue, it consists of the following raw materials by weight percentage:

[0063] 15% organic fluorine silicon modified acrylic resin, 10% phenolic epoxy acrylic resin, 7% aminoacrylic resin, 5% aliphatic polyurethane acrylic resin, 15% acrylic monomer, 1% light curing agent benzophenone and ophthalmic Methyl formylbenzoate 1%, silicon dioxide 0.1%, nano barium sulfate 25%, talcum powder 20%, organic pigment iron blue 0.9%.

[0064] A method for preparing UV-cured peelable blue glue for a touch screen, comprising formulating organic fluorine-silicon modified acrylic resin, phenolic epoxy acrylic resin, aminoacrylic resin, aliphatic polyurethane acrylic resin, acrylic monomer, photocuring agent, two Silicon oxide, barium sulfate, talcum powder, and organic pigments are evenly mixed to obtain a touch-screen UV-curable peelable blue glue.

Embodiment 2

[0066] A touch screen UV curing peelable blue glue, it consists of the following raw materials by weight percentage:

[0067]10% organic fluorine silicon modified acrylic resin, 15% phenolic epoxy acrylic resin, 15% aminoacrylic resin, 5% aliphatic polyurethane acrylic resin, 14% acrylic monomer, 2.5% light curing agent benzophenone and ophthalmic Methyl formylbenzoate 2.5%, silicon dioxide 0.9%, nano barium sulfate 15%, talcum powder 20%, organic pigment phthalocyanine blue 0.1%.

[0068] A method for preparing UV-cured peelable blue glue for a touch screen, comprising formulating organic fluorine-silicon modified acrylic resin, phenolic epoxy acrylic resin, aminoacrylic resin, aliphatic polyurethane acrylic resin, acrylic monomer, photocuring agent, two Silicon oxide, barium sulfate, talcum powder, and organic pigments are evenly mixed to obtain a touch-screen UV-curable peelable blue glue.

Embodiment 3

[0070] A touch screen UV curing peelable blue glue, it consists of the following raw materials by weight percentage:

[0071] 15% organic fluorine silicon modified acrylic resin, 10% phenolic epoxy acrylic resin, 5% aminoacrylic resin, 10% aliphatic polyurethane acrylic resin, 10% acrylic monomer, 2% light curing agent benzophenone and ophthalmic Methyl Formylbenzoate 2%, Silicon Dioxide 1%, Nano Barium Sulfate 25%, Talc Powder 19%, Organic Pigment Cobalt Blue 1%.

[0072] A method for preparing UV-cured peelable blue glue for a touch screen, comprising formulating organic fluorine-silicon modified acrylic resin, phenolic epoxy acrylic resin, aminoacrylic resin, aliphatic polyurethane acrylic resin, acrylic monomer, photocuring agent, two Silicon oxide, barium sulfate, talcum powder, and organic pigments are evenly mixed to obtain a touch-screen UV-curable peelable blue glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com