High-toughness high-activity epoxy resin curing agent and preparation method thereof

An epoxy resin curing and high activity technology, applied in the field of epoxy resin curing agent, can solve the problems of incomplete curing, high brittleness, long gel time, etc., and achieve the effects of shortening the construction period, good impact strength and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

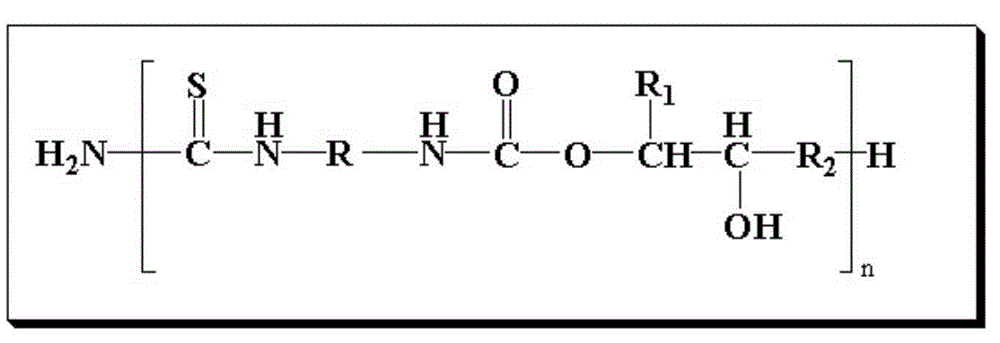

Method used

Image

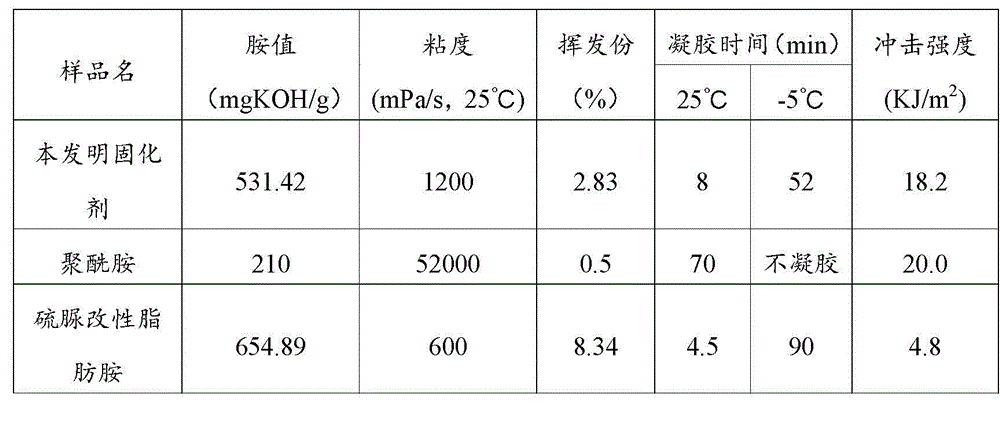

Examples

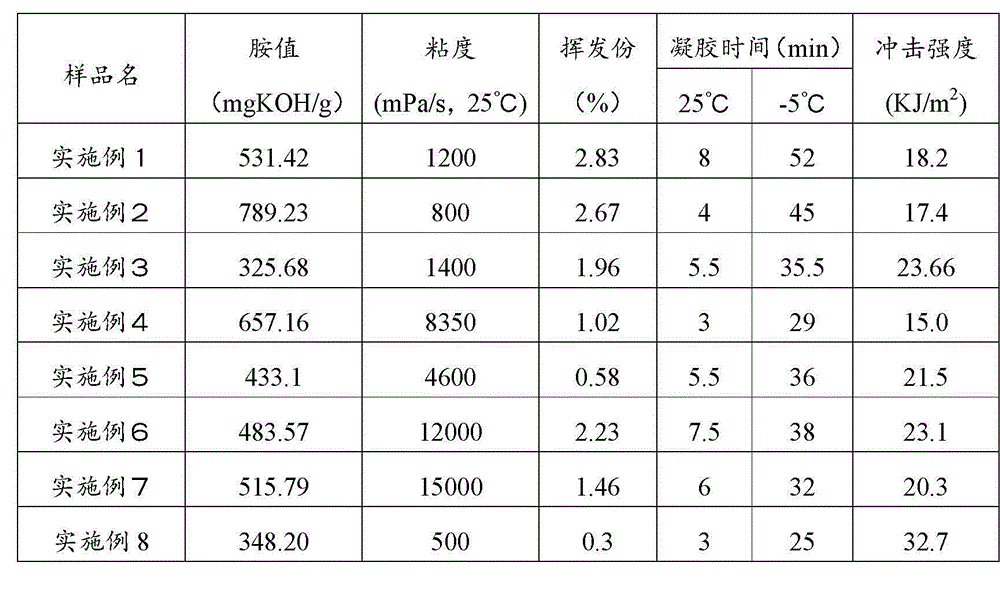

Embodiment 1

[0041] Synthesis steps of high toughness and high activity epoxy resin curing agent:

[0042] 1) Weigh 0.5 mol of ethylene glycol carbonate and 1 mol of tetraethylenepentamine, put the ethylene glycol carbonate into the reactor filled with tetraethylenepentamine in batches, and control the temperature at 50°C±2°C for 2 hours;

[0043] 2) Then weigh 0.5 mol of thiourea, put it into the reactor in batches, heat it with an oil bath to make it fully dissolve, and react at 170°C±2°C for 2 hours;

[0044] 3) After the reaction is completed, cool down the system to 80°C, and then add 1% of the total mass of the product in step 2) of 2,4,6-tris(dimethylaminomethyl)phenol, stir evenly, and discharge the material for storage.

Embodiment 2

[0046] Synthesis steps of high toughness and high activity epoxy resin curing agent:

[0047] 1) Weigh 0.1mol of 2,3-butanediol carbonate and 1mol of ethylenediamine, put the 2,3-butanediol carbonate into the reactor filled with ethylenediamine in batches, and control the temperature at 60 Reaction at ±2°C for 0.5h;

[0048] 2) Then weigh 0.6mol of thiourea, put it into the reactor in batches, heat it with an oil bath to make it fully dissolved, and react at 110°C±2°C for 5h;

[0049] 3) After the reaction is completed, cool the system down to 80°C, and then add 2-mercaptobenzothiazole with 5% of the total mass of the product in step 2), stir evenly, and then discharge and seal.

Embodiment 3

[0051] Synthesis steps of high toughness and high activity epoxy resin curing agent:

[0052] 1) Weigh 1 mol of 1,2-propanediol carbonate and 1 mol of hexamethylenediamine, put the 1,2-propylene glycol carbonate into the reactor containing hexamethylenediamine in batches, and control the temperature at 40±2°C for 1 hour;

[0053] 2) Then weigh 2.5mol of thiourea, put it into the reactor in batches, heat it with an oil bath to make it fully dissolved, and react at 150°C±2°C for 5h;

[0054] 3) After the reaction is completed, lower the temperature of the system to 80°C, and then add 0.5% benzyldimethylamine of the total mass of the product in step 2) into the reactor, stir evenly, and discharge the material for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com