Processing technique and product of bamboo fiber imitated rattan mat

A processing technology, bamboo fiber technology, applied in the field of textile processing, can solve the problems of insufficient toughness of bamboo mat, easy burrs of bamboo mat, poor air permeability, etc., and achieve the effect of increasing hand feeling, unique wear resistance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

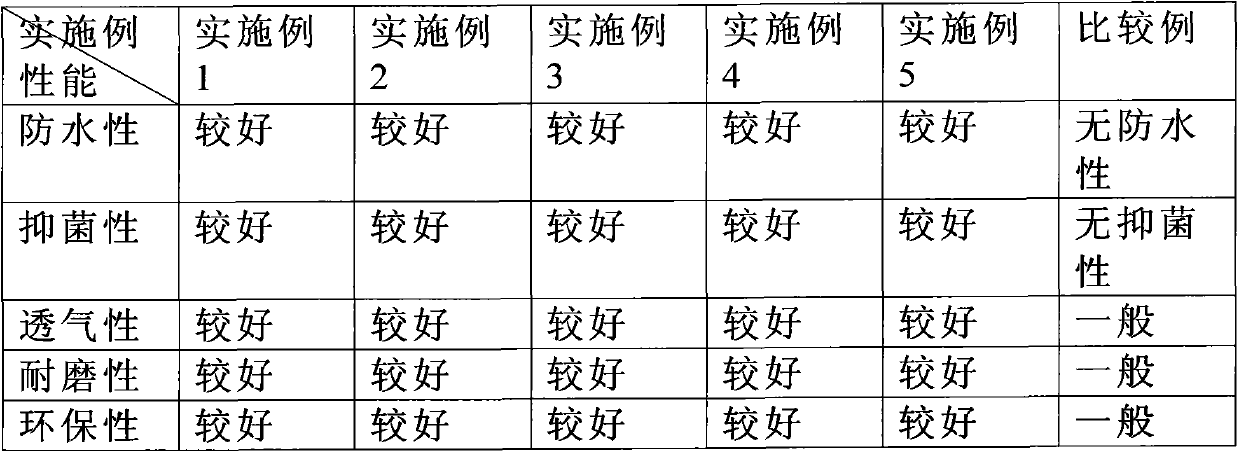

Examples

Embodiment 1

[0035] Select grass waste and add CMC for beating, the degree of substitution is 0.5, the viscosity is 800cp, the temperature is 25°C, the concentration is 2%, the amount of CMC is 0.48kg / t slurry, the pH value of the slurry is 7, the reaction time between CMC and slurry is 20 minutes, the CMC The point of adding is to export the good pulp of the thickener before tapping, and beating at low consistency; semi-finished paper is made through paper processing technology;

[0036] Spray polyethylene emulsion water-repellent directly on the surface of the semi-finished paper for waterproof treatment, and then dry it thoroughly through a dryer; cut the dried semi-finished paper into sheets according to the specifications of the mat, leaving a margin;

[0037] Use sheet paper to wrap the cotton yarn core into rope-like paper and roll it into rolls, use rope-like paper as weft, and bamboo fiber as warp for weaving, so as to obtain the main body of bamboo fiber imitation rattan mat;

[...

Embodiment 2

[0041] Select grass waste and add CMC for beating, the degree of substitution is 0.4, the viscosity is 700cp, the temperature is 20°C, the concentration is 1%, the amount of CMC is 0.5kg / t slurry, the pH value of the slurry is 8, the reaction time between CMC and slurry is 15 minutes, and the CMC Adding point is selected in the unknocked pulp pool, medium-consistency beating; semi-finished paper is made through paper processing technology;

[0042] Spray polyvinylidene chloride emulsion water repellant directly on the surface of the semi-finished paper for waterproof treatment, and then dry it thoroughly through a dryer; cut the dried semi-finished paper into sheets according to the specifications of the mat, leaving a margin;

[0043] Use sheet paper to wrap the cotton yarn core into rope-like paper and roll it into rolls, use rope-like paper as weft, and bamboo fiber as warp for weaving, so as to obtain the main body of bamboo fiber imitation rattan mat;

[0044] The main bo...

Embodiment 3

[0047] Use waste wood raw materials, kraft chemical wood pulp and add modified cellulase for beating: the amount of modified cellulase is 0.47kg / t pulp, the reaction time is 40 minutes, the enzyme use temperature is 50°C, the pH value is 7, and the addition point is selected In the hydropulper, low-consistency beating; through the paper processing process to make semi-finished paper;

[0048] Spray polyorganosilicon water repellent directly on the surface of the semi-finished paper for waterproof treatment, and then dry it thoroughly through a dryer; cut the dried semi-finished paper into sheets according to the specifications of the mat, leaving a margin;

[0049] Use sheet paper to wrap the cotton yarn core into rope-like paper and roll it into rolls, use rope-like paper as weft, and bamboo fiber as warp for weaving, so as to obtain the main body of bamboo fiber imitation rattan mat;

[0050] The main body of bamboo fiber imitation rattan mat under the pressure of 100kgf / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com