Thermosetting resin composition and applications thereof

A resin composition, thermosetting technology, applied in applications, other household appliances, synthetic resin layered products, etc., can solve the problems of poor thermal stability and heat and humidity resistance, poor processability, poor dielectric properties, etc., to achieve curing Effect of short temperature, good toughness, good thermal stability and heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

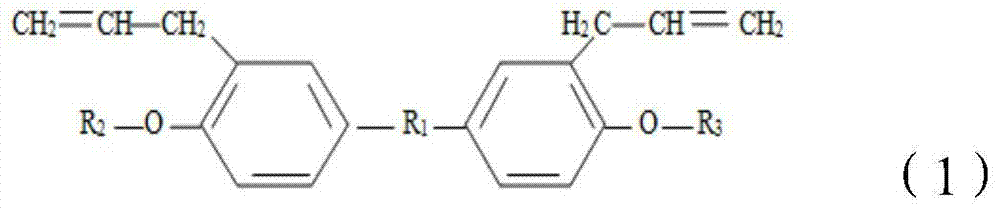

[0099] Add 3000g of water and 30g of sodium hydroxide into the four-neck flask, add 95g of diallyl bisphenol A after the temperature drops to room temperature, put the solution in an ice-salt bath, wait until the temperature drops below 20°C, start adding bromine dropwise Ethane 150g, control the temperature below 20°C, react at low temperature for 30min after the dropwise addition, raise the temperature to 50°C for 2h, stop the reaction, lower the temperature, separate phases, wash with water to obtain ethyl etherified diallyl bisphenol A .

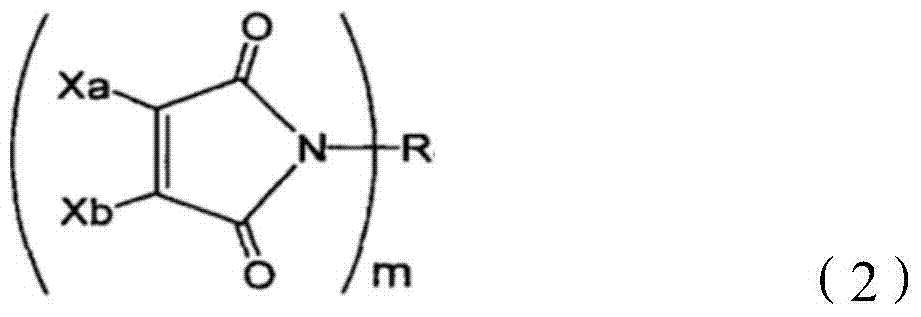

[0100] Take 1 mol of ethyl etherified diallyl bisphenol A and 1 mol of diphenylmethane bismaleimide synthesized above, put them into a flask, heat to 145°C, stir for 30 minutes, pour out and cool to obtain ethyl ether A prepolymer of diallyl bisphenol A and diphenylmethane bismaleimide.

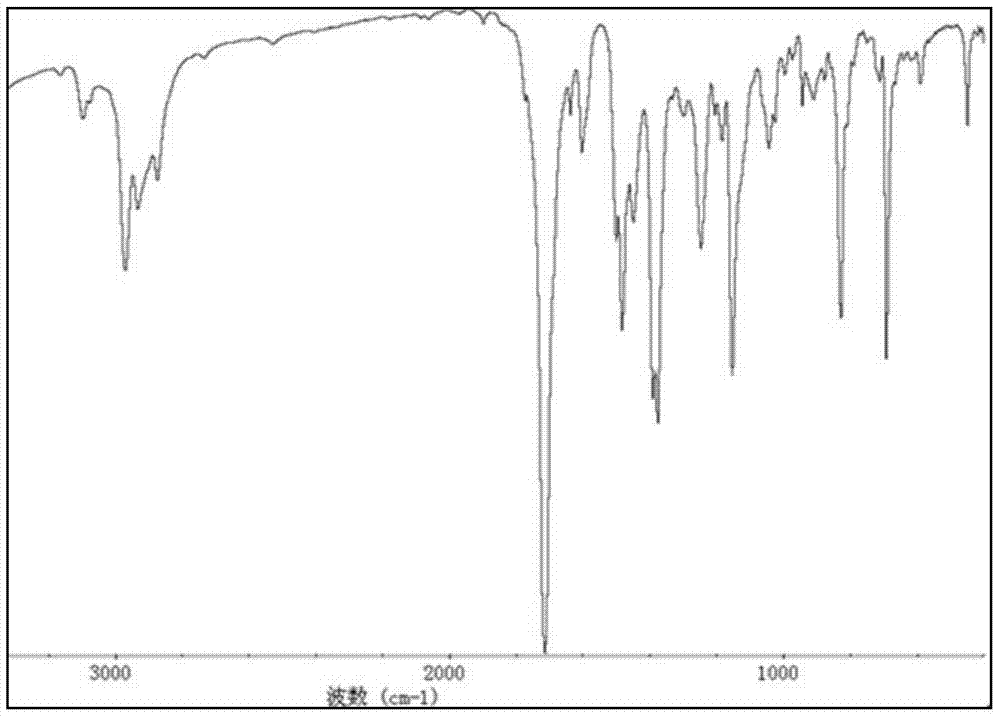

[0101] figure 1 It is the infrared spectrogram of the prepolymer of ethyl etherified diallyl bisphenol A and diphenylmethane bismaleimide synthesized...

Embodiment 2

[0105] Take 1 mol of ethyl etherified diallyl bisphenol A synthesized in Example 1, put 0.5 mol of diphenyl sulfone bismaleimide into a flask, heat to 140° C., stir for 90 minutes, pour it out and cool it down to obtain ethyl alcohol A prepolymer of etherified diallyl bisphenol A and diphenylsulfone bismaleimide.

[0106] Take 30 parts of the prepolymer of ethyl etherified diallyl bisphenol A and diphenylsulfone bismaleimide synthesized above, and 30 parts of polyphenylene ether resin (SA9000) with unsaturated double bonds at the molecular end , 16 parts of bisphenol A cyanate, 12 parts of decabromodiphenylethane, 25 parts of fused silica powder, 2 parts of 2,5-bis(2-ethylhexanoyl peroxy)-2,5-dimethyl Base-3-hexyne, use toluene to dissolve the above compound, and prepare a glue with a suitable viscosity. Use 2116 electronic grade glass cloth to soak the glue, and remove the solvent in an oven at 135°C to obtain a B-stage prepreg sample with a resin content of 54%.

[0107] E...

Embodiment 3

[0109] Take 1 mol of ethyl etherified diallyl bisphenol A synthesized in Example 1, put 0.5 mol of diphenyl sulfone bismaleimide into a flask, heat to 140° C., stir for 90 minutes, pour it out and cool it down to obtain ethyl alcohol A prepolymer of etherified diallyl bisphenol A and diphenylsulfone bismaleimide.

[0110] Take 30 parts of the prepolymer of ethyl etherified diallyl bisphenol A and diphenylsulfone bismaleimide synthesized above, and 30 parts of polyphenylene ether resin (SA9000) with unsaturated double bonds at the molecular end, 12 parts of decabromodiphenylethane, 25 parts of fused silica powder, 2 parts of 2,5-bis(2-ethylhexanoyl peroxy)-2,5-dimethyl-3-hexyne, using toluene to dissolve the above The compound dissolves and makes a glue of the right viscosity. Use 2116 electronic grade glass cloth to soak the glue, and remove the solvent in an oven at 135°C to obtain a B-stage prepreg sample with a resin content of 54%.

[0111] Eight pieces of prepreg and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com