Flux-cored wire for titanium-steel composite board dissimilar joint transition layer and manufacturing method of flux-cored wire

A composite plate and transition layer technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve problems such as cracks and severe embrittlement of welds, achieve excellent strength and toughness, simple manufacturing process, and easy mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1, the particle size is 100 mesh, the chemical composition is V>99.9%, Fe<0.05%, Si<0.05%, Al<0.05%, N<0.04%, C<0.05%, H<0.01% vanadium powder, Dry it at 200°C for 2 hours;

[0032] Step 2, placing the copper strip with a purity of 99.99% and 10×0.4mm on the unwinding machine of the flux-cored wire production line, and cleaning the copper strip with an ultrasonic cleaner to remove oil and other harmful pollutants on the surface of the copper strip;

[0033] Step 3: Roll the red copper strip treated in step 2 into a U-shape by a welding wire forming machine, add the vanadium powder dried in step 1 to it, control the filling rate of vanadium powder to 25%, and then carry out 6-level rough drawing on the welding wire to a diameter of 2.6mm;

[0034] In step 4, the 2.6mm flux-cored welding wire is fine-drawn to a diameter of 1.2mm through 9 grades.

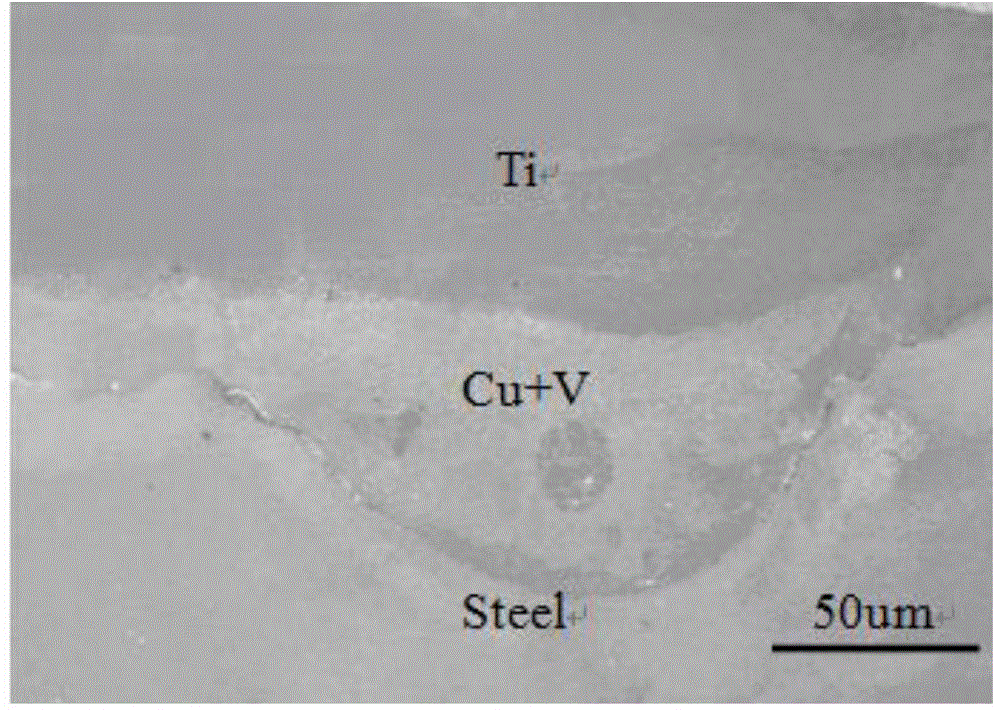

[0035] Copper-vanadium flux-cored welding wire prepared in Example 1 is used to weld titanium-steel (TA1-X80) composit...

Embodiment 2

[0038] Step 1, the particle size is 100 mesh, the chemical composition is V>99.9%, Fe<0.05%, Si<0.05%, Al<0.05%, N<0.04%, C<0.05%, H<0.01% vanadium powder, Dry it at 220°C for 2.5 hours;

[0039] Step 2, placing the copper strip with a purity of 99.99% and 10×0.4mm on the unwinding machine of the flux-cored wire production line, and cleaning the copper strip with an ultrasonic cleaner to remove oil and other harmful pollutants on the surface of the copper strip;

[0040] Step 3: Roll the red copper strip treated in step 2 into a U-shape by a welding wire forming machine, add the vanadium powder dried in step 1 to it, control the filling rate of vanadium powder to 27%, and then carry out 6-stage rough drawing on the welding wire to a diameter of 2.6mm;

[0041] In step 4, the flux-cored welding wire with a diameter of 2.6 mm is fine-drawn to a diameter of 1.2 mm through 9 grades.

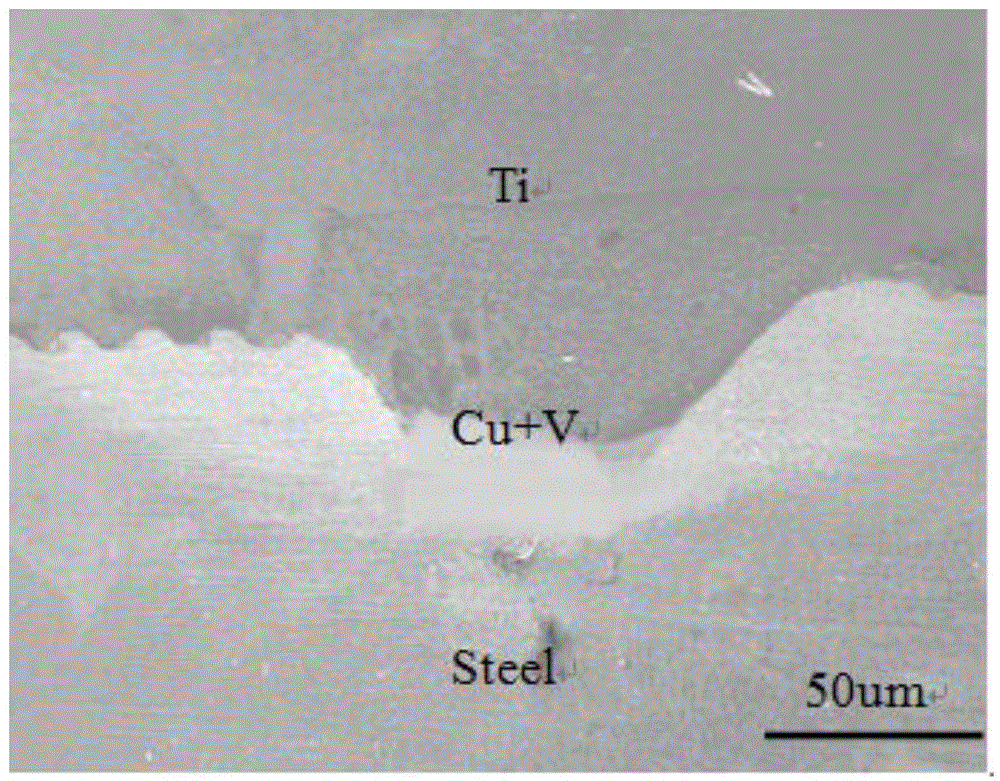

[0042]Use the copper-vanadium flux-cored welding wire prepared in Example 2 to weld the titaniu...

Embodiment 3

[0045] Step 1, the particle size is 100 mesh, the chemical composition is V>99.9%, Fe<0.05%, Si<0.05%, Al<0.05%, N<0.04%, C<0.05%, H<0.01% vanadium powder, Dry it at 250°C for 3 hours;

[0046] Step 2, placing the copper strip with a purity of 99.99% and 10×0.4mm on the unwinding machine of the flux-cored wire production line, and cleaning the copper strip with an ultrasonic cleaner to remove oil and other harmful pollutants on the surface of the copper strip;

[0047] Step 3: Roll the red copper strip treated in step 2 into a U-shape by a welding wire forming machine, add the vanadium powder dried in step 1 to it, control the filling rate of vanadium powder to 30%, and then carry out 6-level rough drawing on the welding wire to a diameter of 2.6mm;

[0048] In step 4, the flux-cored welding wire with a diameter of 2.6 mm is fine-drawn to a diameter of 1.2 mm through 9 grades.

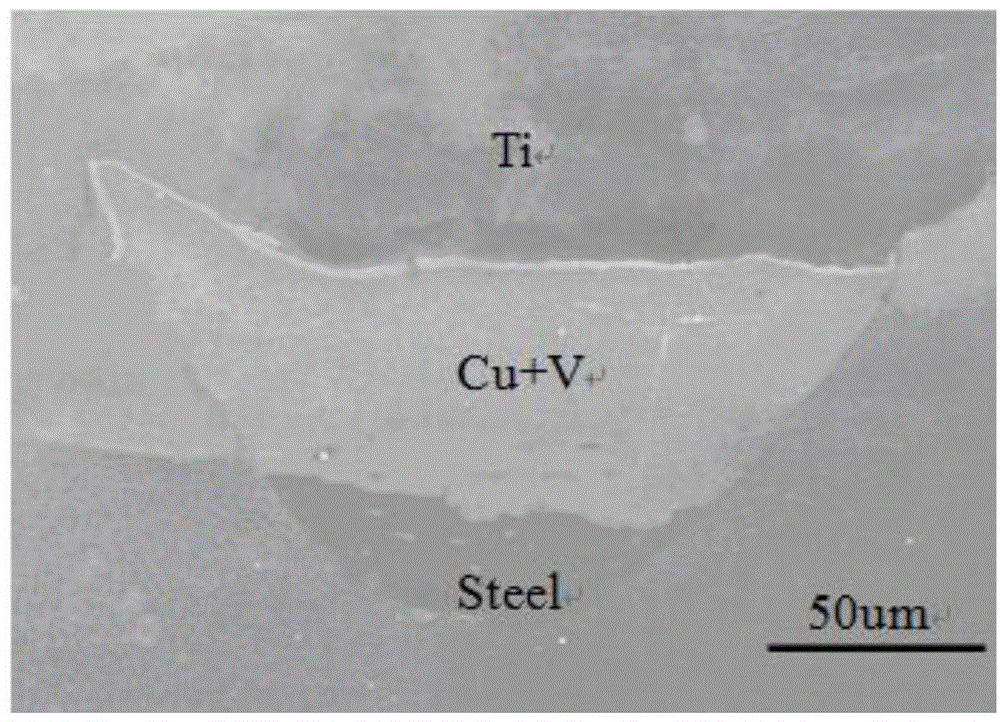

[0049] Use the copper-vanadium flux-cored welding wire prepared in Example 3, cooperate with tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com