Normalizing vessel steel with 460MPa grade yield strength and manufacturing method thereof

A technology of yield strength and manufacturing method, which is applied in the field of high-strength normalizing container steel, can solve the problems of low yield strength and high cost, and achieve the effects of excellent performance, low production cost and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments.

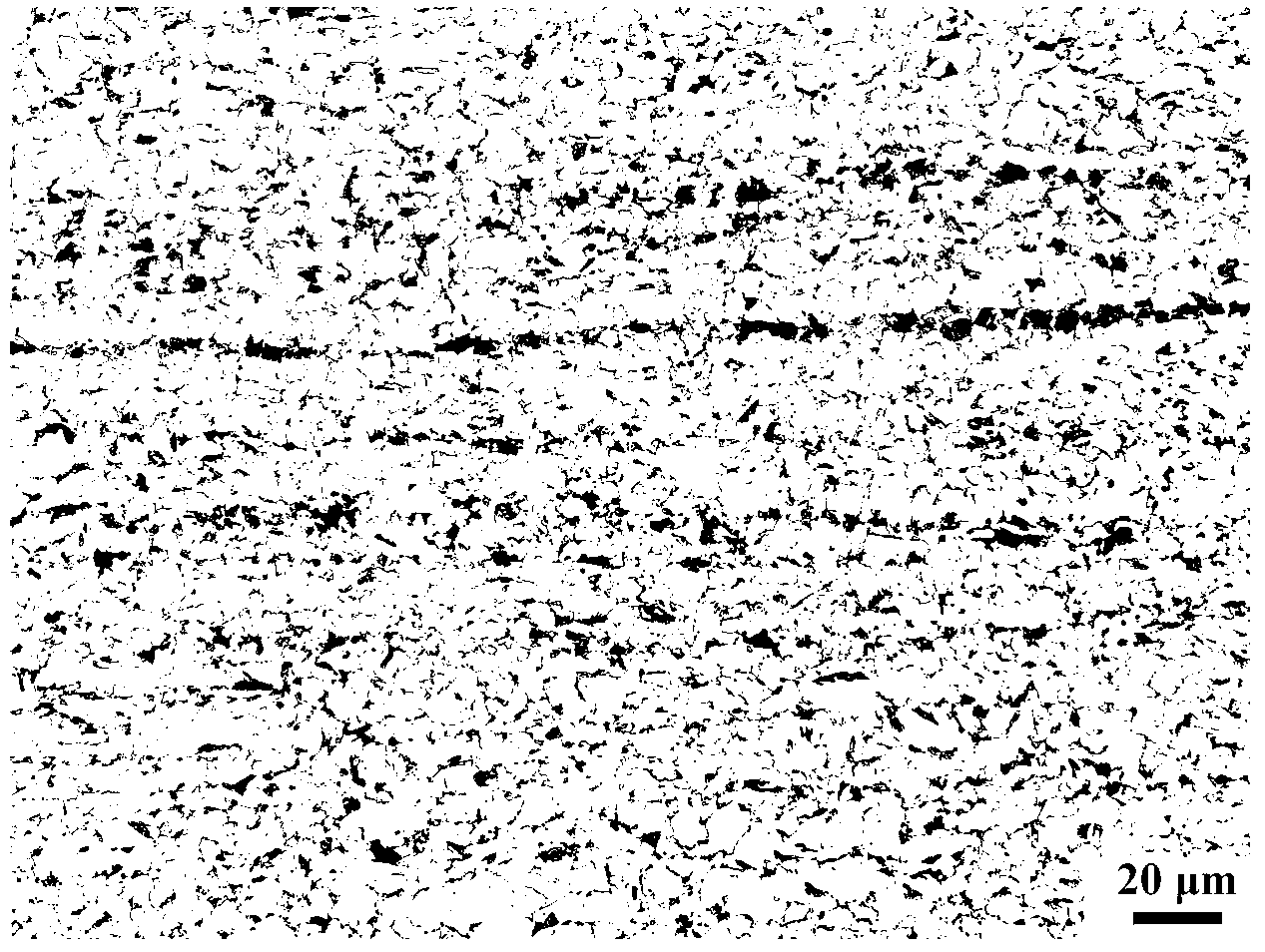

[0026] The chemical compositions of Examples 1 and 2 are shown in Table 1. The hot rolling and heat treatment process parameters adopted are: heating temperature 1150-1250°C, heat preservation for 1.5-2.5 hours, starting rolling temperature 980-1150°C, finishing rolling temperature 850-900°C , cooling speed 8~15℃ / s, final cooling temperature 500~700℃, thickness of finished steel plates are 18mm and 15mm respectively, normalizing temperature 860~930℃, holding time 10~60min.

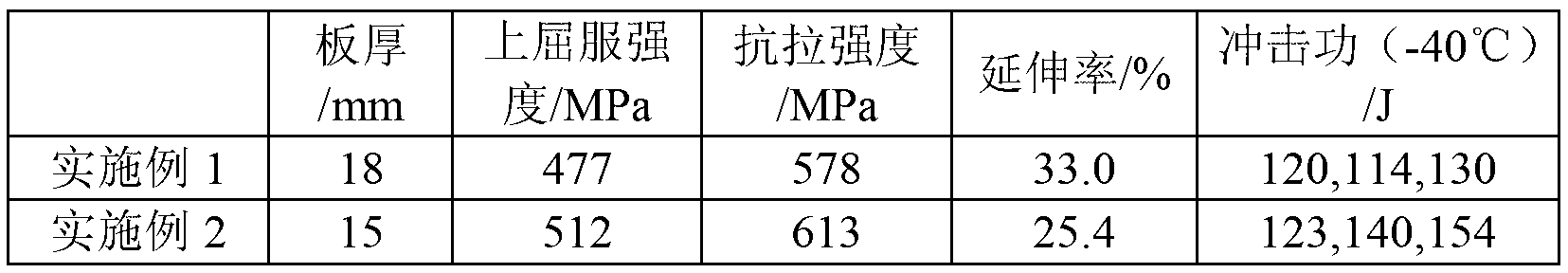

[0027] The steel plate thickness and mechanical properties of Examples 1 and 2 are shown in Table 2.

[0028] Table 1 Chemical composition (wt%) of the normalizing vessel steel involved in Examples 1 and 2 of the present invention

[0029]

C

Si

mn

P

S

Nb

Ti

als

Ceq

Example 1

0.17

0.36

1.51

0.0088

0.0061

0.021

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com