Antibacterial non-woven fabric and preparation method thereof

A technology of non-woven fabrics and antibacterial agents, which is applied in the field of antibacterial non-woven fabrics and its preparation, can solve the problems of not improving the mechanical properties of non-woven fabrics, unsustainable antibacterial effects, and a large number of raw materials for preparation, and achieve excellent broad-spectrum antibacterial properties, Excellent antibacterial performance and chemical stability, mechanical performance and hydrophilic performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

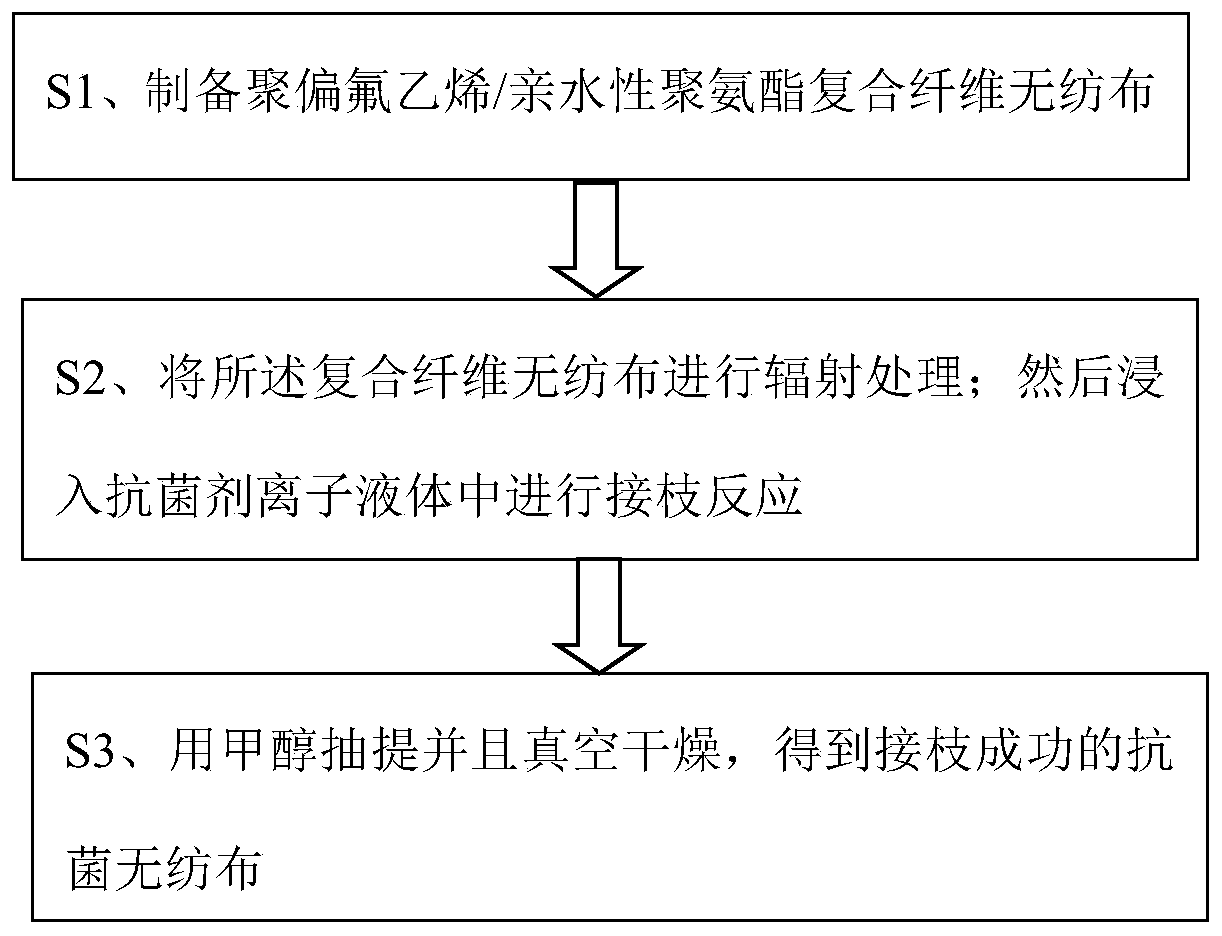

[0032] see figure 1 Shown, the invention provides a kind of preparation method of antibacterial non-woven fabric, comprises the steps:

[0033] S1. Dissolve a predetermined amount of polyvinylidene fluoride and hydrophilic polyurethane in N,N-dimethylformamide solvent and mix evenly to prepare a spinning solution; use electrostatic spinning or wet spinning Said spinning solution is spun, and then dried to prepare composite fiber non-woven fabric;

[0034] S2. Place the composite fiber nonwoven fabric described in step S1 in a sealed bag, replace the air in the sealed bag with nitrogen, and irradiate the composite fiber nonwoven fabric with electron beams at room temperature;

[0035] Then immerse the irradiated composite fiber non-woven fabric in the antibacterial ionic liquid, place it in a constant temperature water bath after sealing, and carry out grafting reaction at a predetermined temperature;

[0036] S3, extract with methanol for 12-24 hours, and dry in vacuum to ob...

Embodiment 1

[0045] A kind of preparation method of antibacterial nonwoven fabric, comprises the steps:

[0046] S1. Dissolving polyvinylidene fluoride and hydrophilic polyurethane in N,N-dimethylformamide solvent and mixing uniformly to prepare spinning solution; in the spinning solution, the mass fraction of polyvinylidene fluoride is 15wt%, the mass ratio of hydrophilic polyurethane to polyvinylidene fluoride is 10:90;

[0047] Then adopt the wet spinning method to spin the spinning solution, then wash with ethanol and dry to prepare composite fiber non-woven fabric; wherein, the process parameters of wet spinning are set as follows: the inner diameter of the spinning needle is 0.61 mm, the liquid feeding rate is 15mL / h; the predetermined winding speed is 15mm / s.

[0048] S2. The composite fiber nonwoven fabric described in step S1 is placed in a polyethylene sealed bag, and after the air in the polyethylene sealed bag is replaced with nitrogen, electron beams are used to irradiate the...

Embodiment 2-3

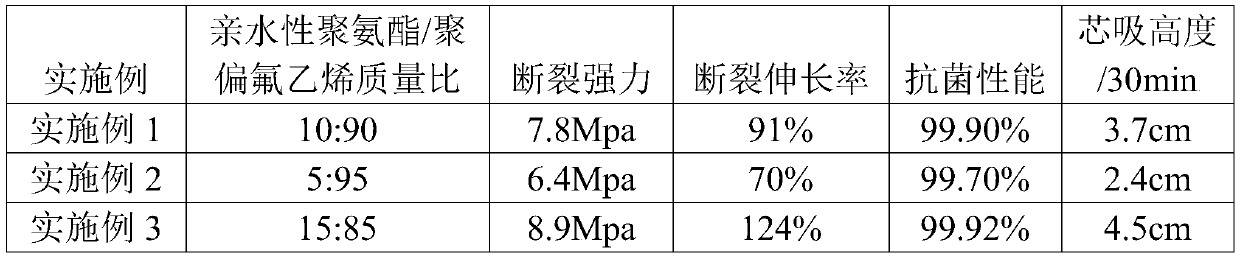

[0070] The difference from Example 1 is that the mass ratio of water-based polyurethane to polyvinylidene fluoride is different, as shown in Table 2, and other steps are the same as in Example 1, and will not be repeated here.

[0071] Table 2 is the setting of hydrophilic polyurethane and polyvinylidene fluoride mass ratio in embodiment 1-3 (antibacterial test sample is Staphylococcus aureus)

[0072]

[0073] Please refer to Table 2, as the amount of polyurethane increases, the mechanical properties of the composite fiber nonwovens increase. With the increase of hydrophilic polyurethane, the breaking strength of the composite fiber increases gradually, and the breaking elongation also increases. The addition of hydrophilic polyurethane also improves the hydrophilic performance of antibacterial nonwovens to a certain extent. The surface of pure polyvinylidene fluoride material is extremely hydrophobic. When it is used as a filter material to treat water-based fluids, due ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com