Fraction lining for mine hoist and preparation method of fraction lining

A mine hoist and friction pad technology, applied in the field of friction pads and their preparation, can solve problems such as inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of friction lining for mine hoist of the present invention is as follows:

[0027] Step 1: First add 100 parts of powdered nitrile rubber into the mixer, then add 80 parts of phenolic resin, 30 parts of nano-silica, and 12 parts of magnesium oxide, and mix for 5 minutes; then add 3 parts of zinc oxide and 8 parts of iron oxide yellow , 2 parts of accelerator M, 2 parts of accelerator DM, 3 parts of anti-aging agent RD, 3 parts of anti-aging agent D, 2 parts of DOP, 5 parts of stearic acid, and knead for 5-10 minutes; finally add 2 parts of sulfur and knead for 5 minutes. The temperature in the mixer is controlled at 60-80°C, and the mixing time is 15-20 minutes. After the mixing is completed, put the mixed powder into the inner bag without tying the mouth.

[0028] Step 2: Place the powder raw materials mixed in step 1 for 17-24 hours to cool to room temperature, and then carry out the first rubber mixing. The purpose is to preliminarily refine t...

Embodiment 2

[0032] Basically the same as Example 1, the difference is that the raw material ratio: 100 parts of nitrile rubber, 100 parts of phenolic resin, 38 parts of nano white carbon black, 15 parts of magnesium oxide, 4 parts of zinc oxide, 10 parts of iron oxide yellow, 1 part of agent M, 1 part of accelerator DM, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent D, 1 part of DOP, 6 parts of stearic acid, and 2 parts of sulfur.

Embodiment 3

[0034] It is basically the same as Example 1, except that the raw material ratio is: 100 parts of nitrile rubber, 120 parts of phenolic resin, 45 parts of nano-silica, 18 parts of magnesium oxide, 5 parts of zinc oxide, 12 parts of iron oxide yellow, 2 parts of agent M, 2 parts of accelerator DM, 3 parts of anti-aging agent RD, 2 parts of anti-aging agent D, 1 part of DOP, 7 parts of stearic acid, and 3 parts of sulfur.

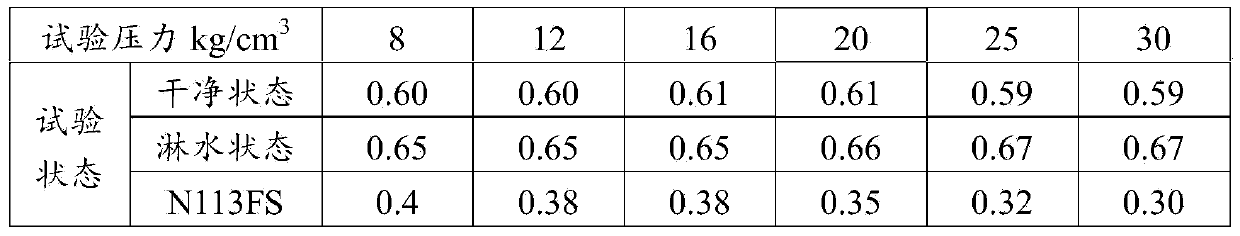

[0035] After testing, the main parameters of the friction coefficient and physical and mechanical properties of the friction lining are shown in Table 1 and Table 2, respectively.

[0036] Table 1

[0037]

[0038] Table 2

[0039] serial number

[0040] The results show that the various technical indicators of the friction lining can meet the requirements of JB / T10347-2002, and some indicators are higher than the standard, which can meet the current use requirements and future development needs of friction lifting equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com