Cellulose-reinforced polyurethane/epoxy resin interpenetrating polymer network hard composite foam material and preparation method thereof

A technology of epoxy resin and interpenetrating network, which is applied in the field of foam materials and its preparation, can solve the problems of poor sound absorption performance and low mechanical properties, and achieve the effect of good sound absorption effect and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

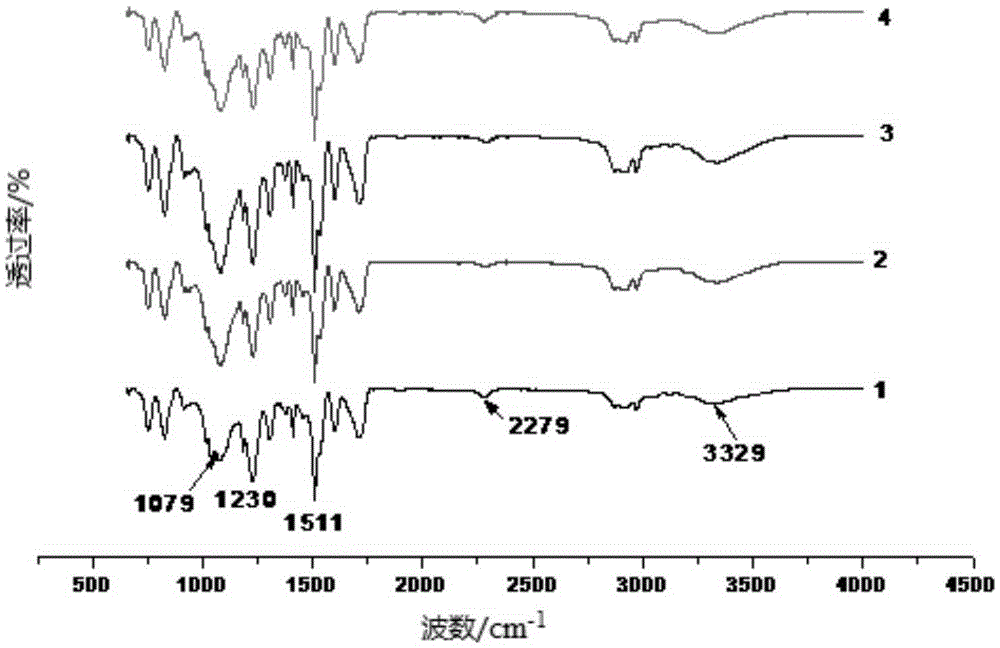

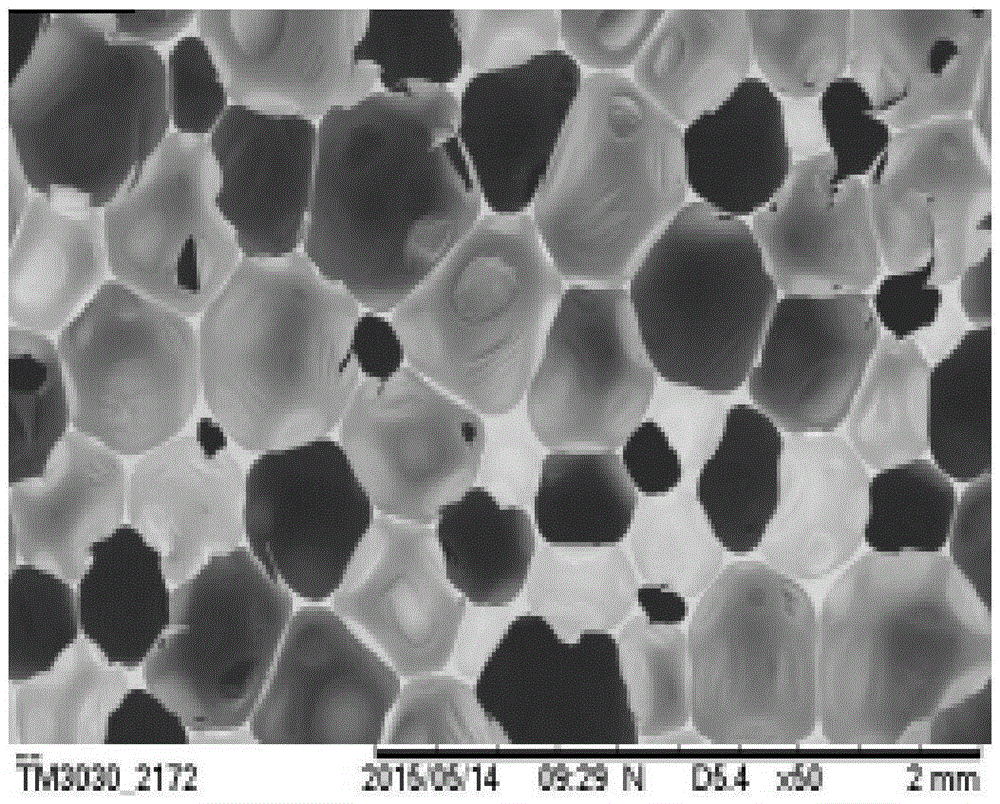

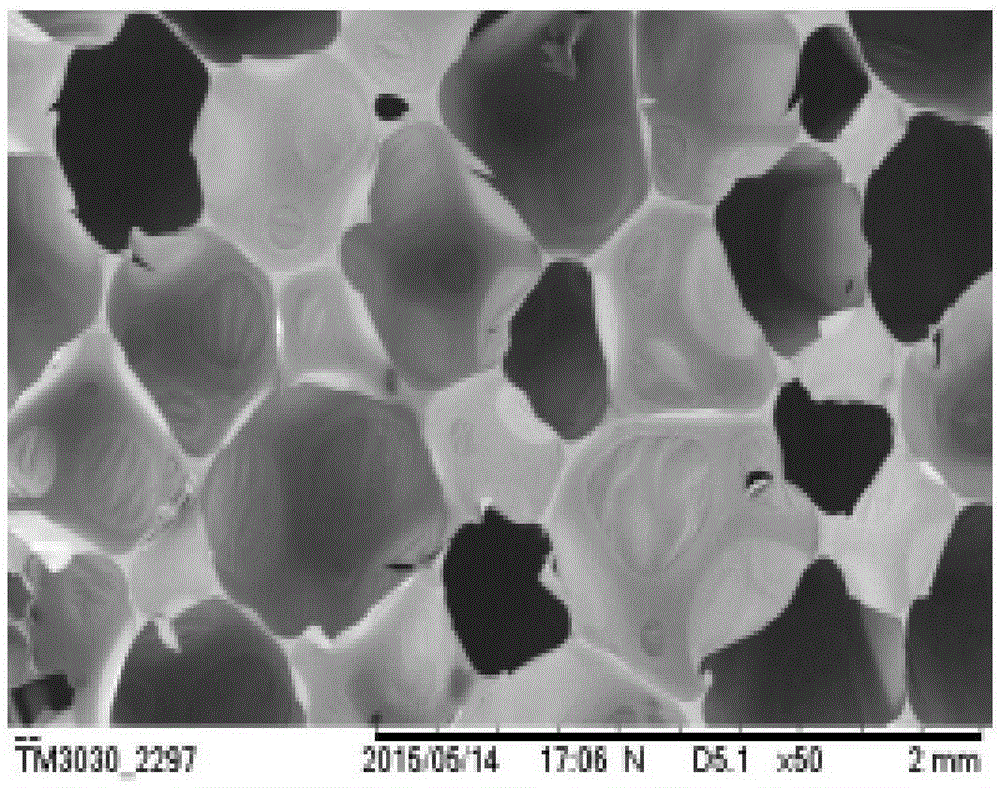

[0041] Specific embodiment 1: This embodiment is a cellulose-reinforced polyurethane / epoxy resin interpenetrating network rigid composite foam material, and the sound absorption performance of the cellulose-reinforced polyurethane / epoxy resin interpenetrating network rigid composite foam material is 80 %~92%;

[0042] The cellulose-reinforced polyurethane / epoxy resin interpenetrating network rigid composite foam material consists of 8 to 12 parts of polyether polyol, 10 to 16 parts of isocyanate, 0.05 to 0.25 parts of water, 2 parts by weight ~3.5 parts of foaming agent, 0.05 part~0.2 part of foam stabilizer, 0.04 part~0.15 part of initiator, 0.1 part~5 part of hydrosol of nanocellulose fiber with a mass percentage of 1%, 0.05 part~0.4 part of chain extension agent, 0.05-0.4 parts of cross-linking agent and 0.1-8 parts of epoxy resin;

[0043] Described mass percent is that the hydrosol of the nanocellulose fiber of 1% is specifically prepared according to the following steps...

specific Embodiment approach 2

[0053] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the polyether polyol is a mixture of one or two of polyether polyol 4110 and polyether polyol 330; The isocyanate is a mixture of one or two of diphenylmethane diisocyanate and polymethyl polyphenylisocyanate; the foam stabilizer is silicone oil; the initiator is triethylenediamine, dilauric acid One or a mixture of two of dibutyltin, stannous octoate, potassium oleate and potassium octoate; the water is deionized water. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0054] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the foaming agent is a physical foaming agent. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com