Chemically mechanical polishing solution

A chemical machinery, polishing liquid technology, applied in polishing compositions containing abrasives, etc., can solve the problems of large average particle size of secondary particles, monodispersity, poor dispersibility, etc., to achieve narrow particle size distribution, small polishing damage, high flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 (preparation of 100 grams of polishing liquid)

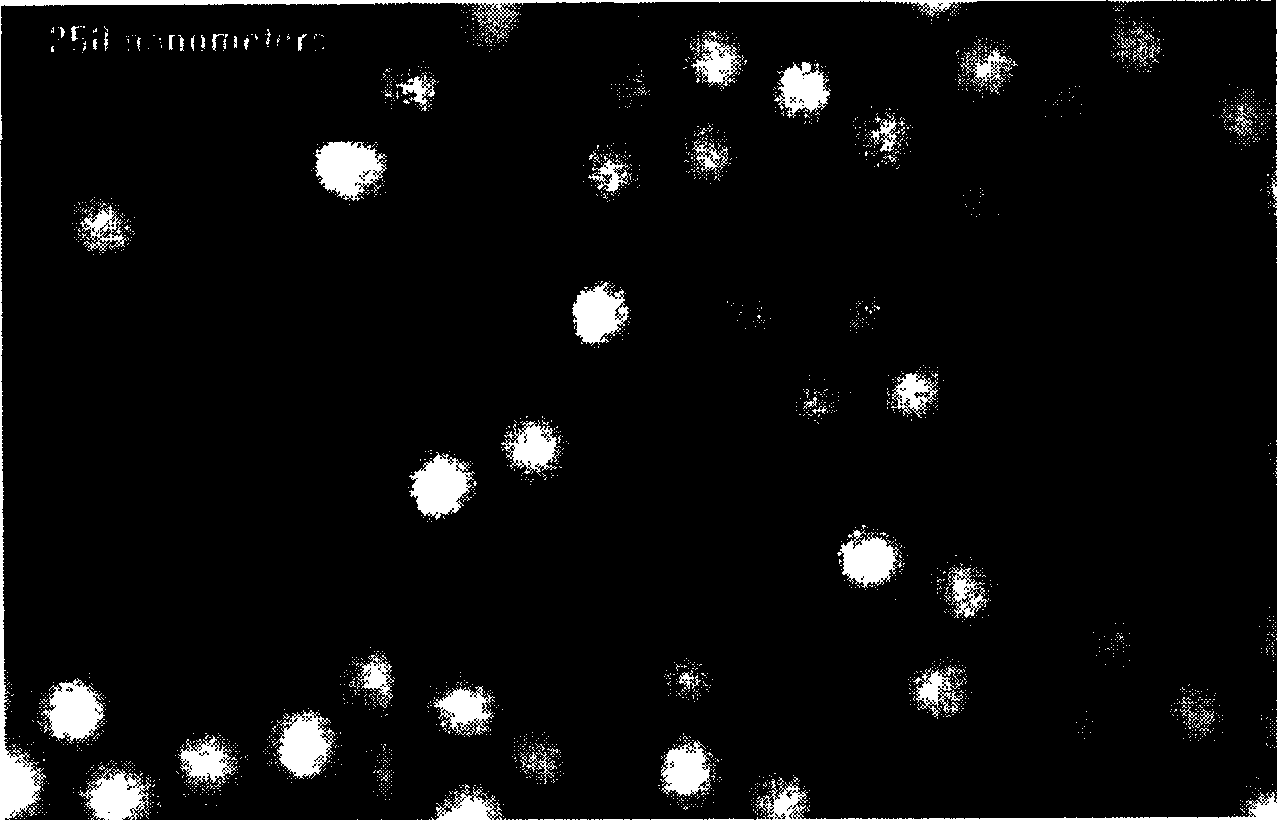

[0027] Take 30 grams of spherical nano-mesoporous SiO 2 Powder, the average particle size is 70nm, add 0.8 grams of 1,2-propylene glycol surface treatment agent, 8 grams of polyoxypropylene polyoxyethylene block polyether as a dispersion stabilizer, under the stirring and dispersion of 3000rpm, add high-purity 56 grams of ionized water were stirred and dispersed for 1.5 hours, and 5.2 grams of ethanolamine (also surface treatment agent and pH regulator) were added dropwise to adjust the pH value to 10, and the stirring was continued for 1 hour to obtain 100 grams of the polishing solution of the present invention.

[0028] Among them: spherical nano-mesoporous SiO 2 The powder is prepared as follows:

[0029] Dissolve 6.0g of cetyltrimethylammonium bromide and 10.56g of F127 (PEO-PPO-PEO, average molecular weight 11000) in 600g of ammonia solution (36.96g of ammonia water), heat at 35°C for 5 minutes, and w...

Embodiment 2

[0035] The difference from Example 1 is:

[0036] Using 10 grams of mesoporous SiO with a particle size of 30 nm 2The powder is abrasive, add 1 gram of polyvinyl alcohol as a dispersion stabilizer, add 79 grams of high-purity deionized water, add 9.2 grams of ethanolamine dropwise to adjust PH=10, and the SiO in the final polishing solution 2 The percentage content is 10%.

Embodiment 3

[0038] The difference from Example 1 is:

[0039] Mesoporous SiO 2 The particle size of the powder is 120nm, add 10 grams of 1,2-propylene glycol surface treatment agent, add the dispersion stabilizer of 5 grams of polyoxypropylene polyoxyethylene block type polyether, adopt 4 grams of triethanolamine as the pH regulator, adjust PH=12, add 51 grams of high-purity deionized water, the results are as follows: the average particle size is 120nm, and the average removal rate of the silicon dioxide layer is 3700 Å / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com