Metal particles, process for manufacturing the same, and process for manufacturing vehicle components therefrom

Inactive Publication Date: 2007-03-01

FUJI JUKOGYO KK

View PDF3 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0030] The vehicle component obtained by use of the production process of the invention are light weight because of the formulation and has good mechanical properties, such as excellent fatigue strength at about 300° C. A piston for engine having excellent strength, in part

Problems solved by technology

In addition to the above, it is difficult to use a casting method to the mixture of Mg and Si, because the viscosity of the mixture in the liquid state is high, comparing with that of the magnesium metal.

As a result, it is difficult to cast the magnesium melt containing 5 to 10 wt.

Further, since the solidifying rate of the magnesium melt containing silicon is slow, magnesium silicide particles formed in the melt grow by the end of the solidification.

The magnesium alloy obtained in this way does not have excellent mechanical properties.

When the magnesium alloy in a semi-fused state is subjected to injection molding, the mechanical properties of the alloy are not good.

Further, the magnesium melt containing silicon has a high viscosity, and the casting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Login to View More

Abstract

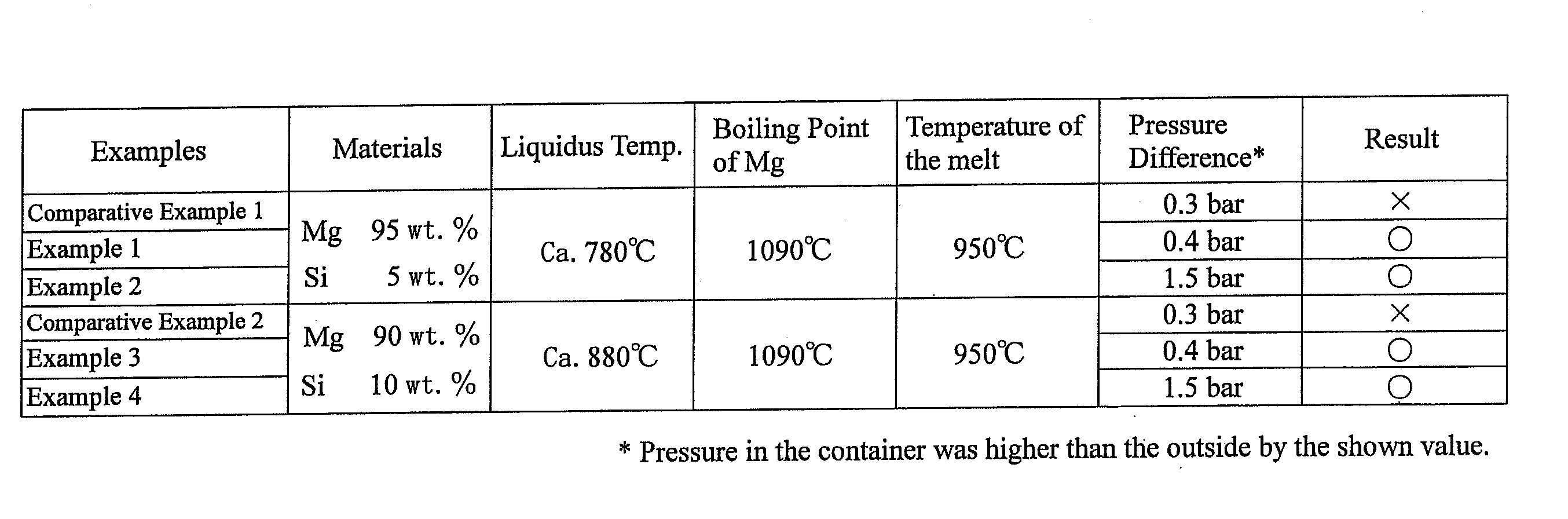

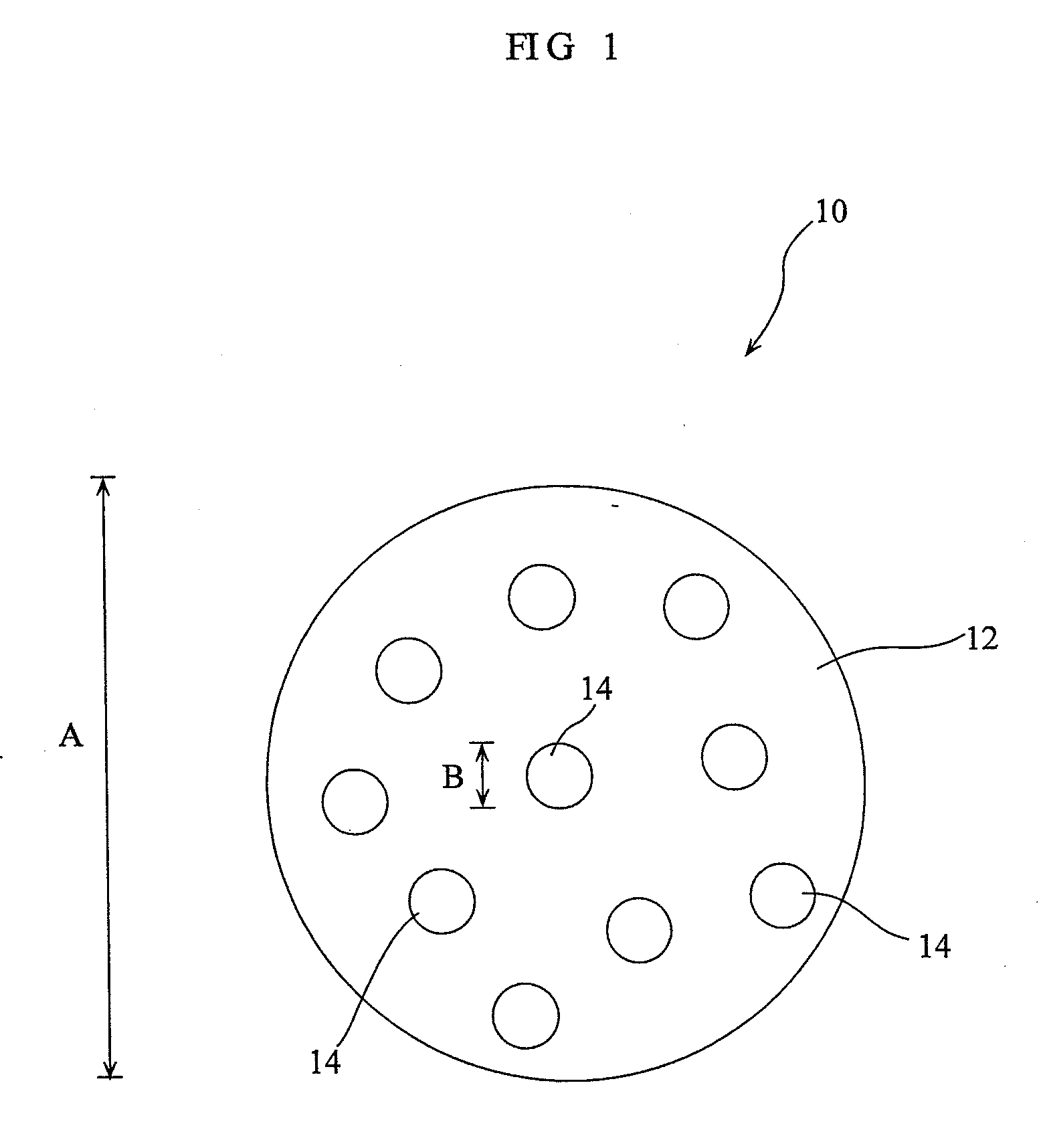

Metal particles approximately in the form of spheres having a mean diameter of about 40 μm to about 100 μm, including magnesium silicide particles having a mean diameter of about 1 μm to about 10 μm uniformly dispersed in the metal particles, the metal particles being obtained by mixing about 90 wt. % to about 95 wt. % of magnesium and about 5 wt. % to about 10 wt. % of silicon, and the magnesium silicide particles being formed in the metal particles by the reaction of the magnesium and the silicon.

Description

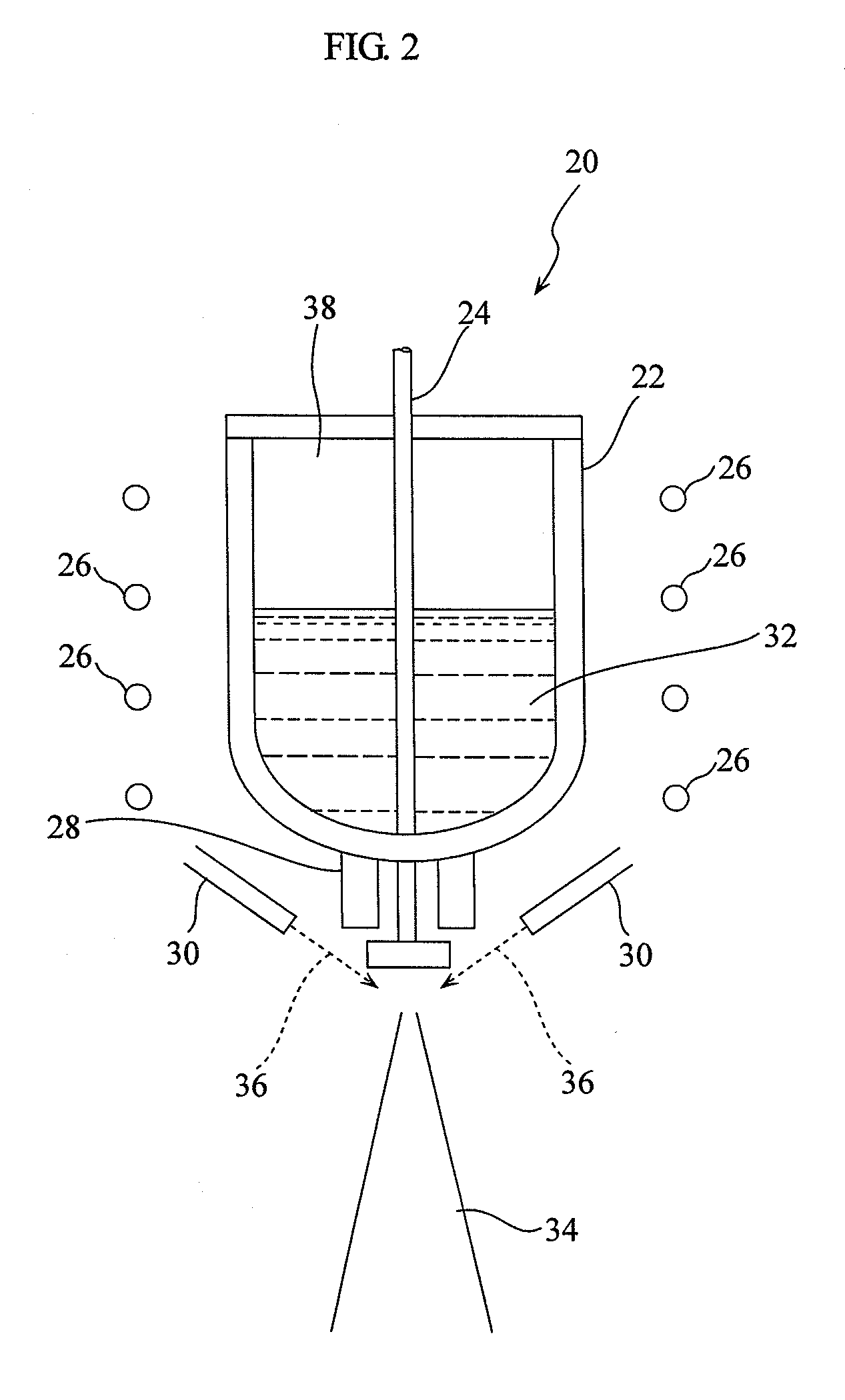

CROSS REFERENCE TO RELATED APPLICATIONS AND INCORPORATION BY REFERENCE [0001] This application is based upon and claims the benefit of priority from the prior Japanese Patent Application No. 2005-244247, filed on Aug. 25, 2005; the entire content of which is incorporated herein by reference. BACKGROUND OF THE INVENTION [0002] 1. Field of the Invention [0003] The present invention relates to magnesium-based metal particles comprising magnesium silicide dispersed therein, a process for manufacturing the magnesium-based metal particles, process for manufacturing components for use in a vehicle, and components manufactured thereby. [0004] 2. Discussion of the Related Art [0005] Magnesium is widely used for preparing so-called light alloy because of the low specific gravity thereof. It is also known that the mechanical properties such as a rigidity of a product made from magnesium alloy are improved when the material magnesium alloy contains therein magnesium silicide (Mg2Si) particles i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22F9/06B22F3/115B22F1/05

CPCB22F1/0011B22F5/008B22F9/082B22F2998/00B22F2998/10C22C23/00B22F9/08B22F2202/07B22F3/14B22F3/17B22F1/05

Inventor YANO, YUTAKA

Owner FUJI JUKOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com