Method for processing fast powder sherardizing surface coat

A technology of powder galvanizing and surface coating, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of difficult metal material heat treatment, no zinc/aluminum co-infiltration surface alloy layer, patent Application refusal and other problems to achieve the effect of fast heating speed, high utilization rate of heat source, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

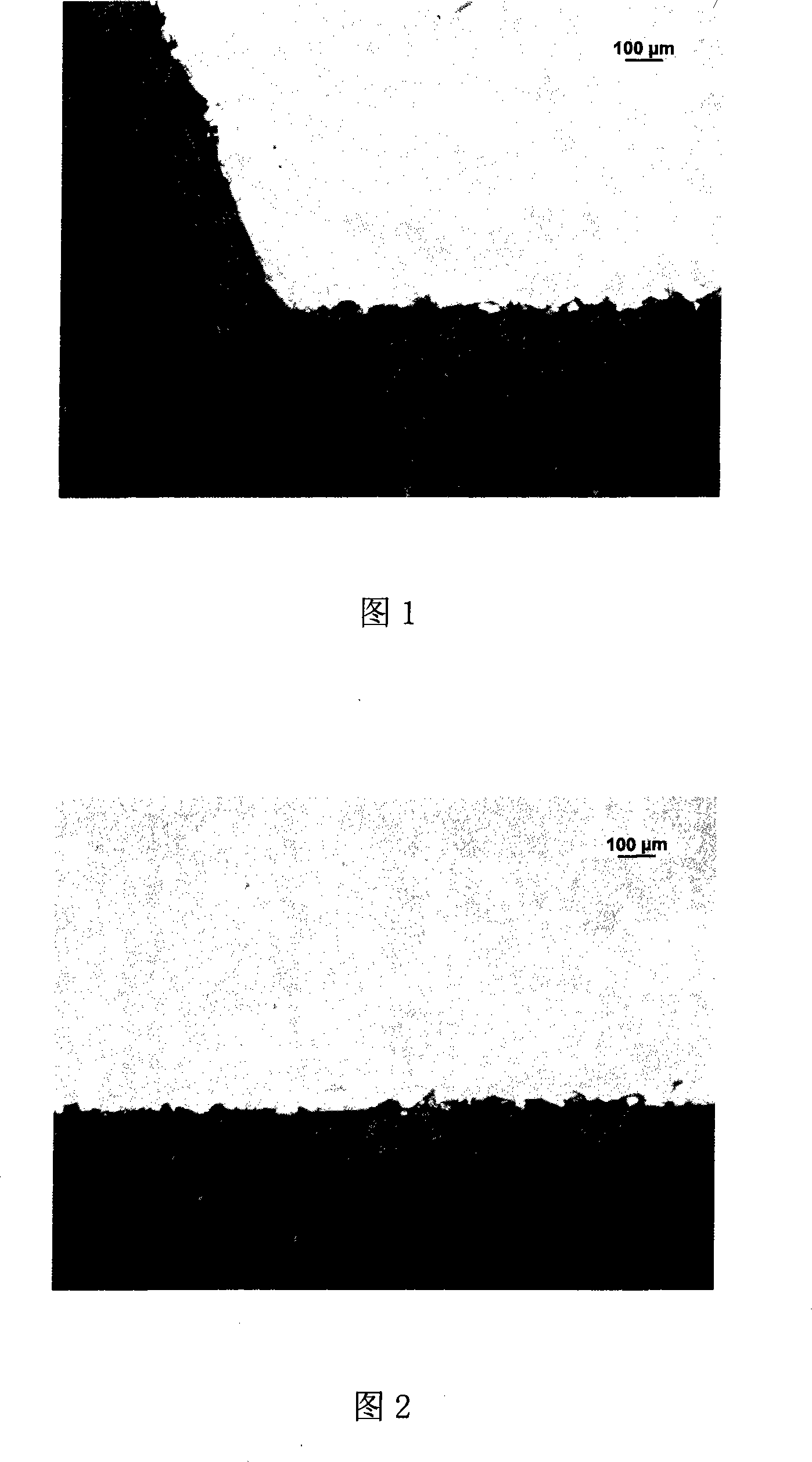

[0034]In a crucible made of heat-resistant ceramics is placed a 325 mesh volume ratio (the following ratios are volume ratios) of 30% zinc powder, 200 mesh 30% alumina powder and 100 mesh 40% quartz sand mixed uniformly. The buried surface has a small amount of rusty metal gaskets. Place the crucible on the turntable in the 800W microwave heating furnace and heat it under normal pressure. The heating time is 15 minutes, and then it is cooled in air. The surface of the metal gasket can be A zinc-iron alloy infiltrated layer with an average thickness of 39.3 microns was obtained. Figures 1 and 2 are the metallographic photos of the zinc-iron alloy infiltration layer quickly prepared on the surface of the metal gasket by microwave heating. They respectively show the distribution of the zinc-iron alloy infiltration layer at the corners and planes of the metal gasket. It can be seen that regardless of the corners A layer of uniform thickness can be obtained anywhere or on a plane.

Embodiment 2

[0036] Place 200 mesh 30% zinc powder, 325 mesh 10% aluminum powder, 1% ammonium chloride powder, and the rest 120 mesh quartz sand filler in the alumina crucible, mix the sherardizer, and remove the oil and rust metal gasket It is embedded in the sherardizer, the crucible is sealed with water glass or refractory cement and then placed in an 800W microwave oven for heating for 20 minutes. A zinc-aluminum-iron alloy layer with an average thickness of 50 microns can be obtained on the surface of the metal gasket.

Embodiment 3

[0038] In the alumina crucible are placed 200 mesh 10% zinc powder, 325 mesh 30% aluminum powder and 3% ammonium chloride powder, and the rest is 200 mesh alumina (Al 2 O 3 ) Mixing the filler uniformly with the sherardizer, embed the pre-treated metal gasket in the sherardizer, seal the crucible and place it in a 800W microwave oven for 30 minutes to heat and keep it warm. Aluminum-zinc can be obtained on the surface of the metal gasket. Ferroalloy infiltration layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com