Prestressed reinforcement and non-prestressed reinforcement combined H-shaped reinforced concrete sheet pile and manufacture method thereof

A technology of non-prestressed steel bars and reinforced concrete sheet piles, which is applied to sheet pile walls, manufacturing tools, ceramic molding machines, etc., can solve the problems of not being able to protect deep foundation pits, mud pollutes the environment, and large surrounding spaces, and achieves The effect of high degree of civilized construction, shortened construction period and guaranteed tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

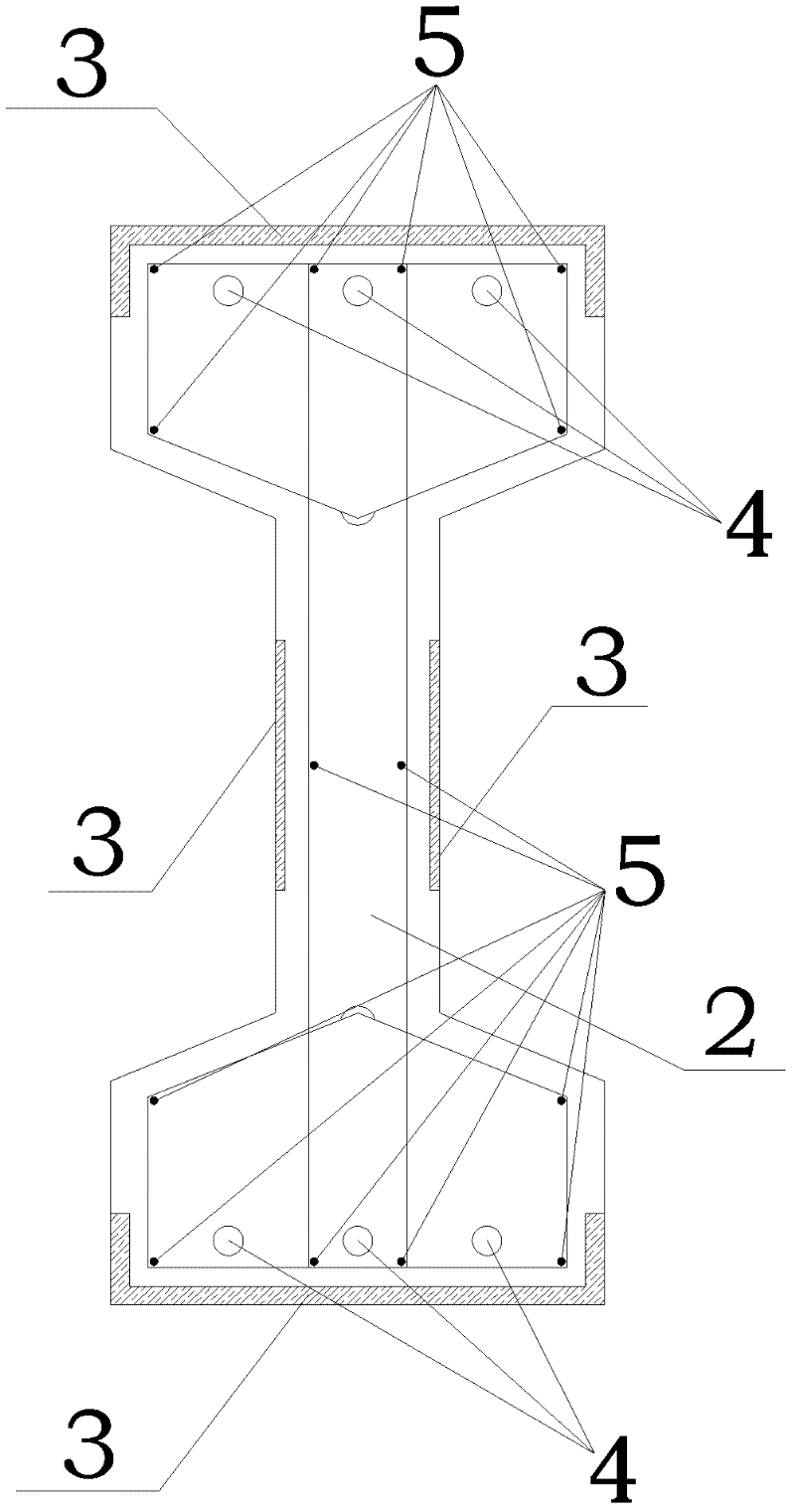

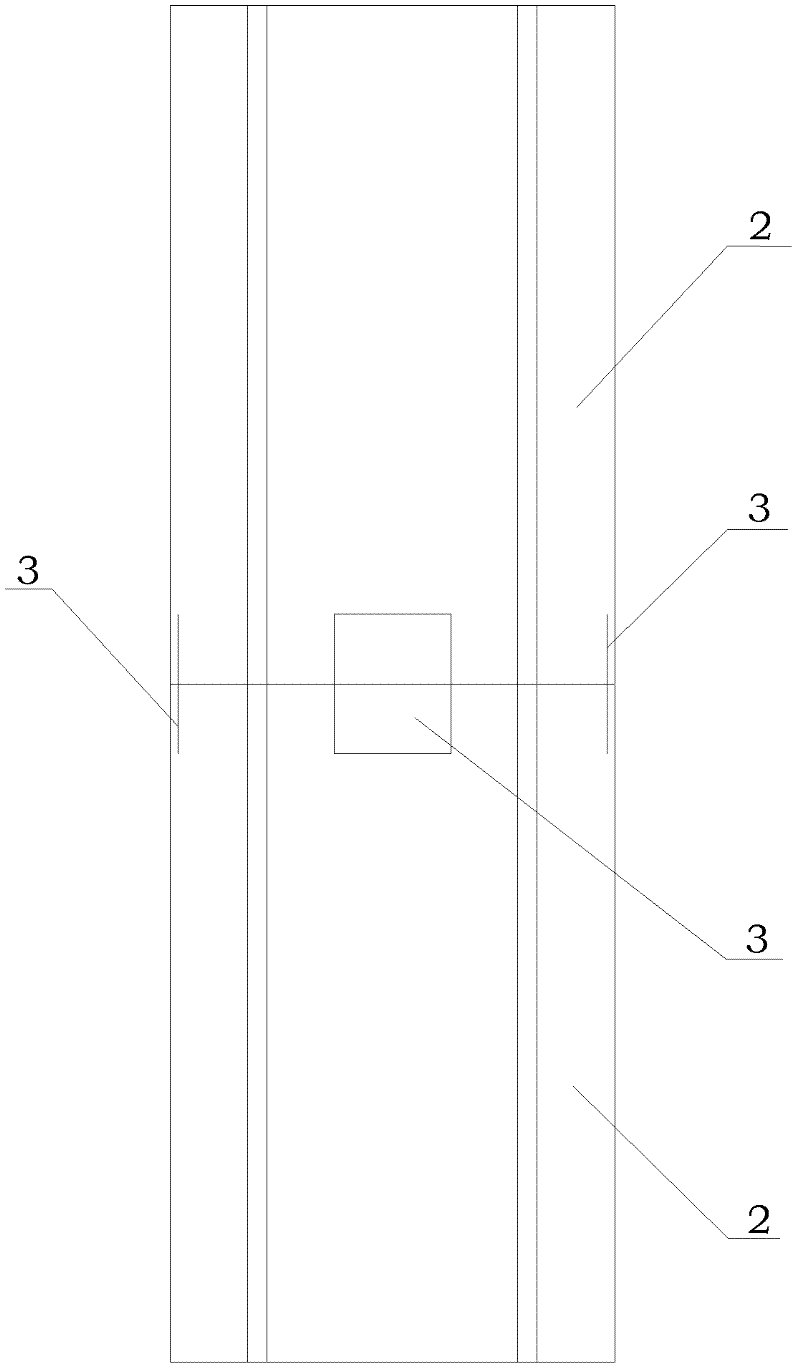

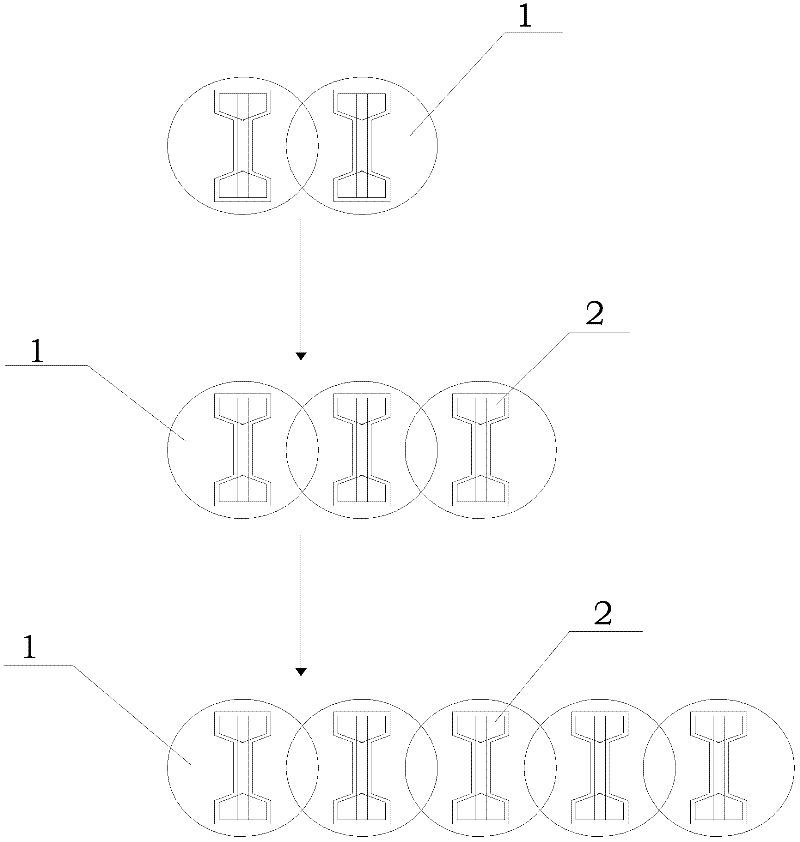

[0026] Such as Figure 1-3 As shown, a prestressed and non-prestressed H-shaped reinforced concrete sheet pile, the H-shaped reinforced concrete sheet pile is an "I"-shaped reinforced concrete sheet pile structure, and is divided into single-section and multi-section according to the length of the sheet pile Sheet piles are divided into multiple sections when the length is long, and if multiple sections are required to connect piles, pre-embedded iron 3 must be installed at the joints. The H-shaped reinforced concrete sheet pile 2 is equipped with prestressed steel bars 4 and non-prestressed steel bars 5 at the same time. Described prestressed reinforcing bar 4 and non-prestressed reinforcing bar 5 are provided with many (can be prepared according to the size requirement of actual pile, as in the present embodiment prestressed reinforcing bar 4 prepares 6, non-prestressed reinforcing bar 5 prepares 14) , respectively evenly distributed in the H-shaped reinforced concrete shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com