Composite packaging bag

A packaging bag and composite technology, applied in the field of packaging bags, can solve the problems of printing pattern wear, PP melting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

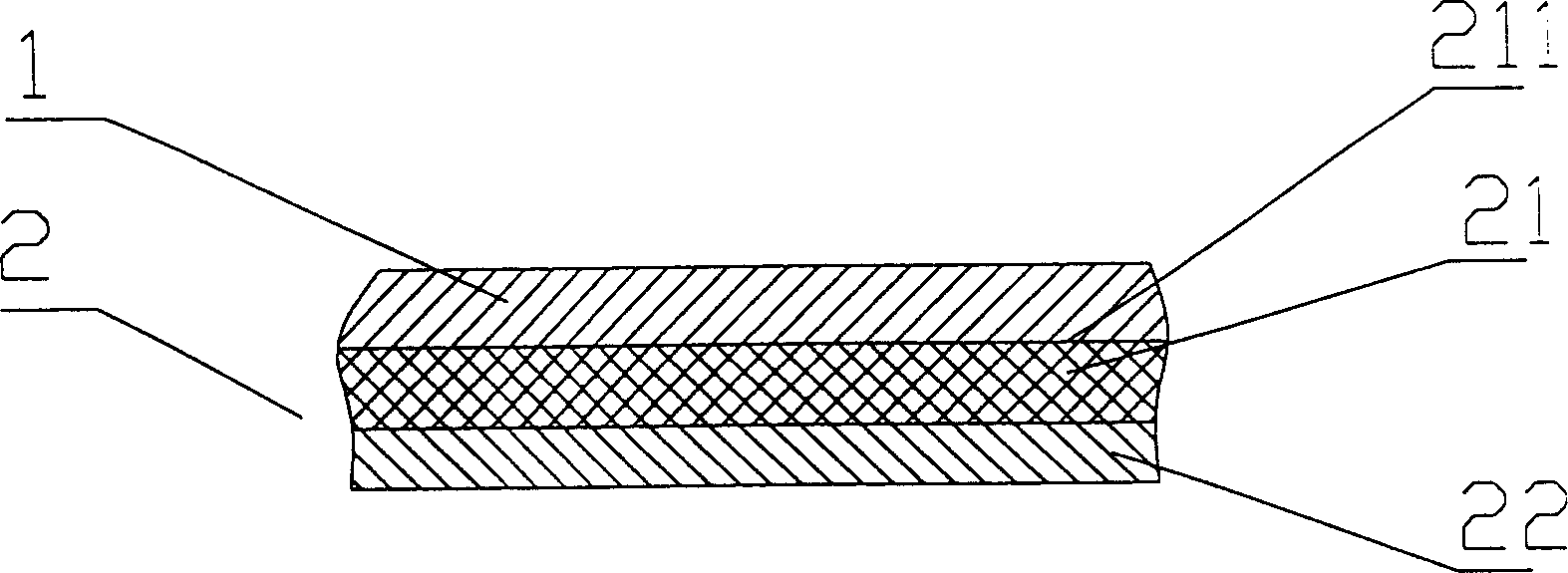

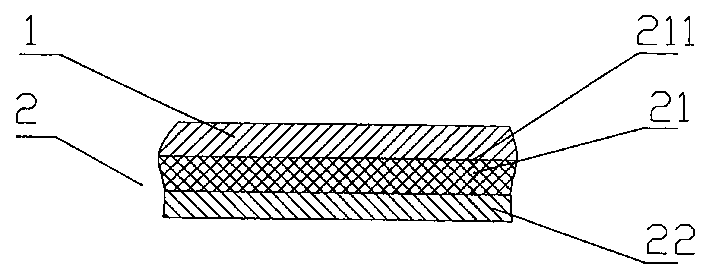

[0011] See attached figure 1 , the present invention is mainly made of PE, PP or other plastic materials, and it includes an inner layer 1 and an outer layer 2 bonded together by pressing, and the inner layer 1 is made of PE material, and the outer layer 2 is made of bidirectional Stretched PP material. The outer layer 2 is divided into two layers, including a tensile layer 21 and a heat-resistant layer 22 . The inner surface of the tensile layer 21 is the printing surface 211 , that is, the printed pattern is interposed between the inner and outer layers, which can effectively protect the pattern from erosion.

[0012] Material

longitudinal tensile strength

Transverse Tensile Strength

Longitudinal elongation at break

Transverse elongation at break

BOPP

135

260

120

40

PP

80

40

420

550

This product

/

120

/

334

[0013] From the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com