Multicore bundling self-supporting optical fiber cable and manufacturing method thereof

A self-supporting fiber optic cable and bundling technology, applied in the direction of light guides, optics, optical components, etc., can solve problems such as inability to branch laying, achieve the effects of reducing the use of raw materials, enhancing tensile strength, and simplifying production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

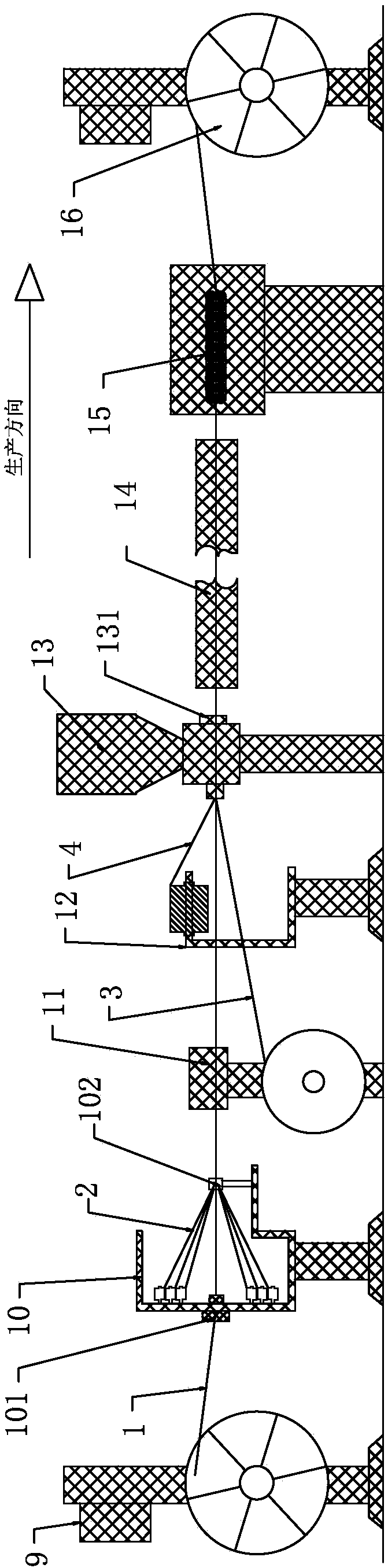

[0027] The multi-core bundled self-supporting optical cable and its manufacturing method of the present invention will be described in detail below with reference to the accompanying drawings.

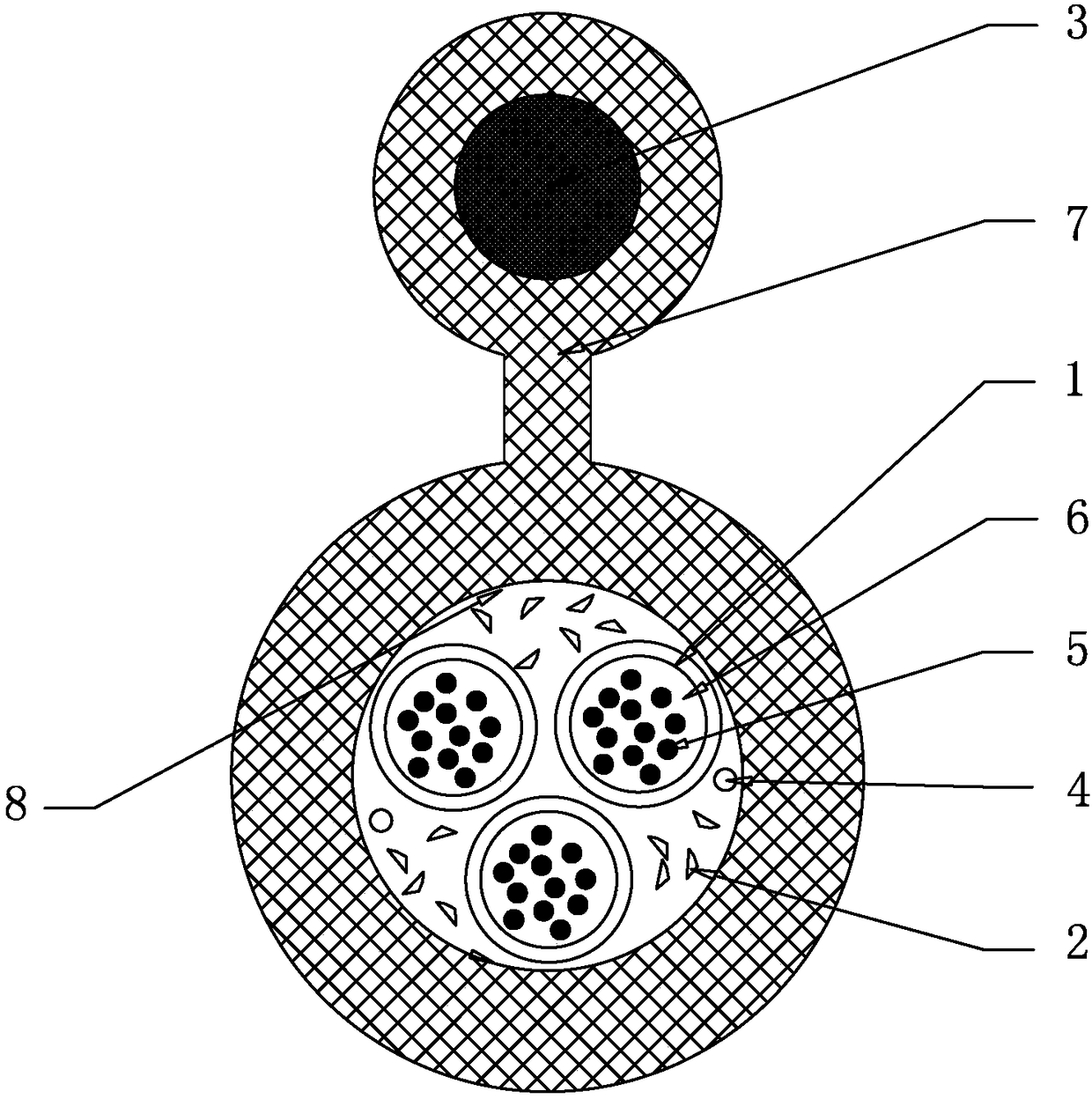

[0028] Such as figure 1 As shown, the multi-core bundled self-supporting optical cable and the manufacturing method thereof of the present invention include a suspension wire part and an optical cable part, and the suspension wire part and the optical cable part are connected by suspenders; the optical cable part is composed of a cable core plus two torn The rope 4 is composed of an extruded low-smoke, halogen-free, flame-retardant sheath 7.

[0029] The cable core 8 is composed of a plurality of loose tubes 1 and aramid yarns 2 placed in parallel. The arrangement of the aramid yarn can wrap the loose tube to prevent the loose tube 1 from sticking to the outer low-smoke, halogen-free, flame-retardant sheathing material.

[0030] Compared with the traditional process, the cabling proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com