Embedded type light wallboard steel structure building structure and construction method

A light-weight wallboard and steel structure technology, which is applied to building structures, building components, buildings, etc., can solve the problem of occupying too much building land, poor building experience for residents, and great differences in thermal expansion properties between steel and light-weight wallboards, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

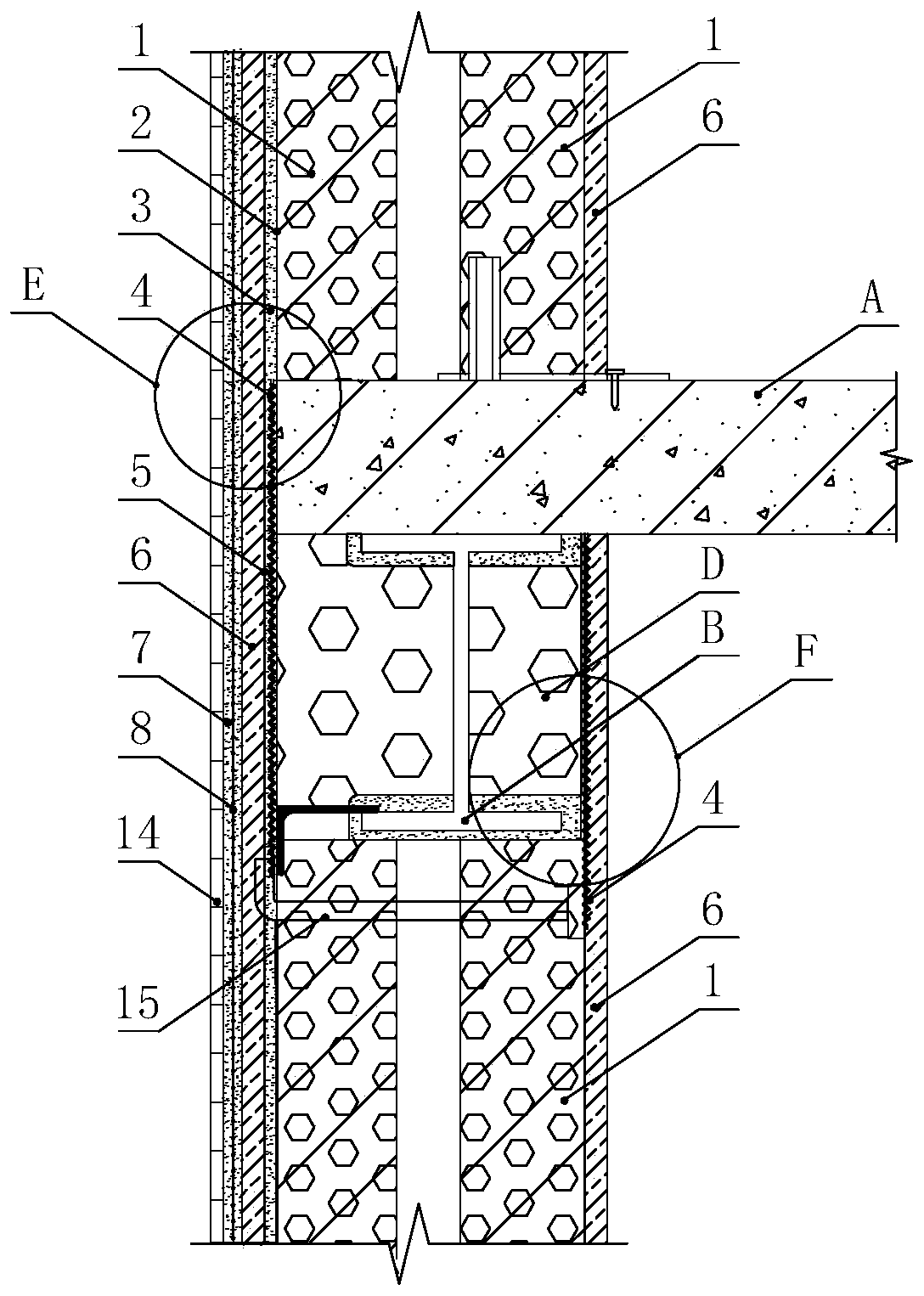

[0092] An embedded lightweight wall panel steel structure building structure, including an interior wall panel structure, a steel beam node structure, a corner column node structure, a flat column node structure and a wall panel splicing joint structure;

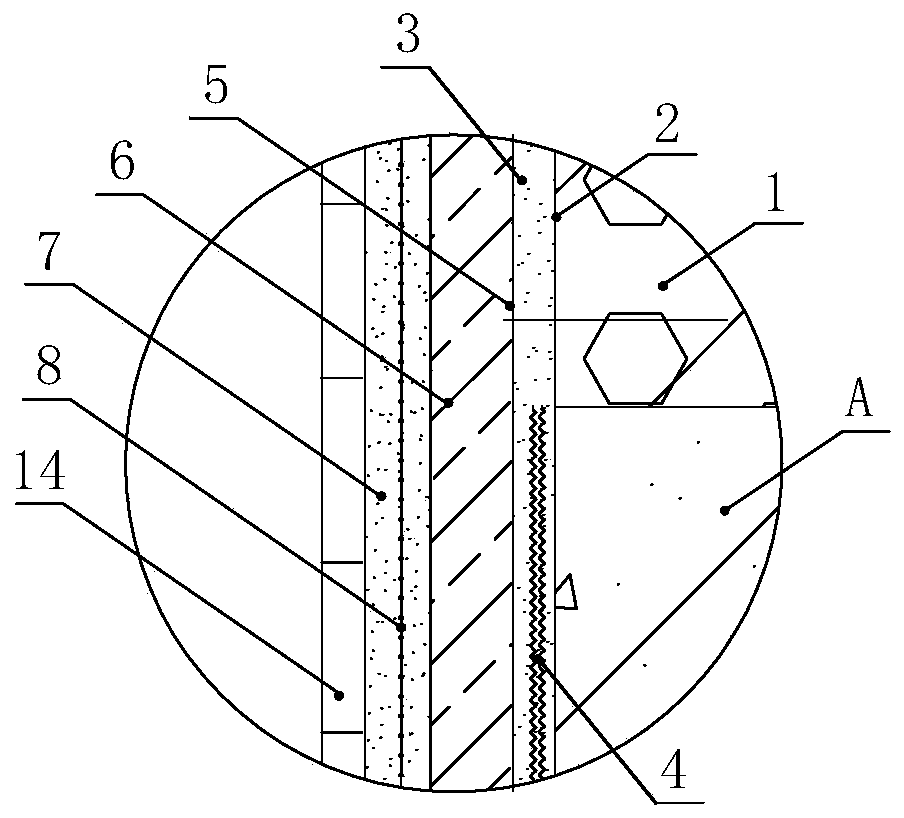

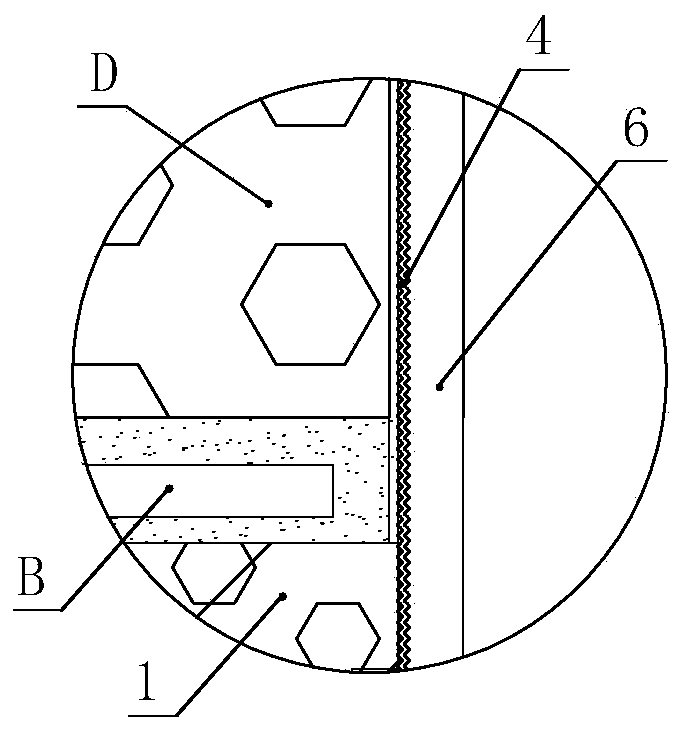

[0093] The interior wall panel construction (see attached Figure 7 ) includes the steel beam groove filling wall of the interior wall and the two side structures of the lightweight wall panels of the interior wall located below it, and the steel beam groove filling wall of the interior wall has the same structure as the two sides of the lightweight wall panels of the interior wall below it The surface of the interior wall steel beam groove filling wall is laid with glass fiber mesh cloth 4, and the glass fiber mesh cloth extends to cover part of the wall surface of the lower interior wall light wallboard, and the interior wall steel beam groove filling wall and The wall surface of the light-weight wallboard of the lower inn...

Embodiment 2

[0112] The method is a construction method of a built-in lightweight wall panel steel structure building structure described in claim 3, the construction method is carried out after the lightweight wall panels are installed and meet the quality requirements, including: seam construction method, The construction method of the exterior wall surface of the exterior wall panel, the construction method of the interior wall surface of the exterior wall panel and the wall surface of the interior wall panel:

[0113] S1 seam construction method:

[0114] S11 Joint construction between lightweight wall panels and steel structure corner columns or steel structure flat columns;

[0115] S111 filling the sponge board (10) in the seam;

[0116] S112 Install PE rods (11) on the inner and outer seams of the seams;

[0117] S113 Fill polyurethane foam caulking agent (13) between PE rod and sponge board;

[0118] S114 Inject weather-resistant sealant (12) into the exposed gap between the PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com